Leather cutting knife

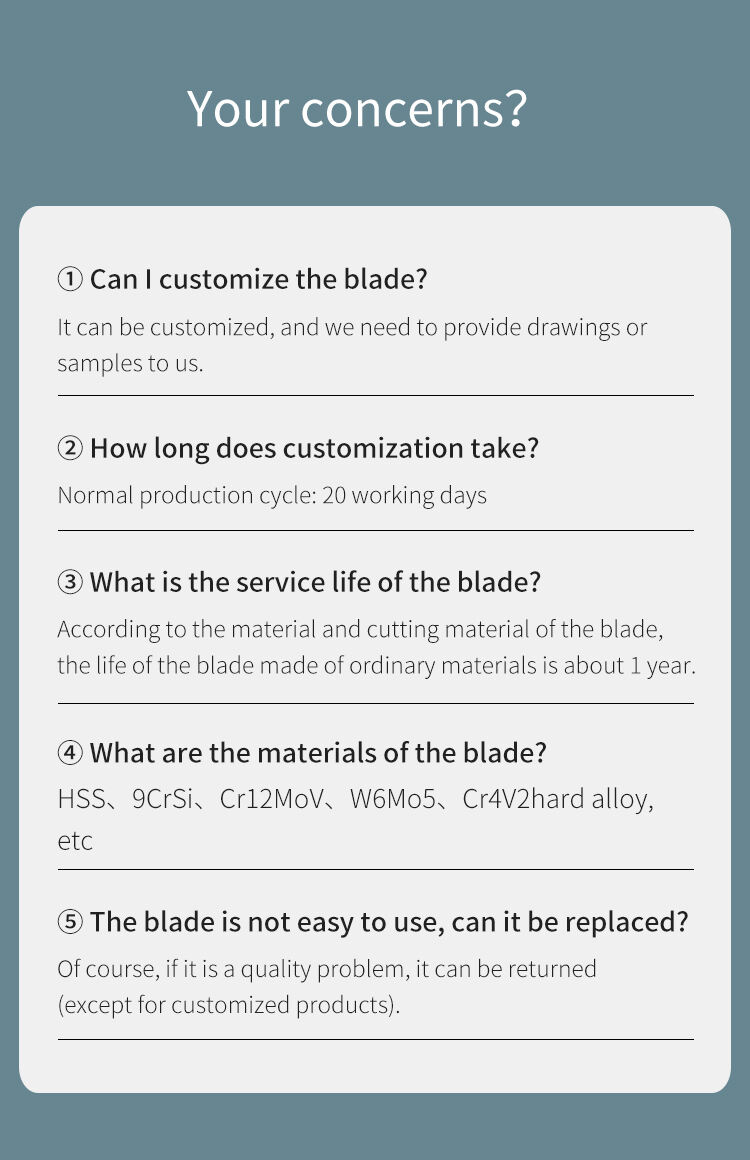

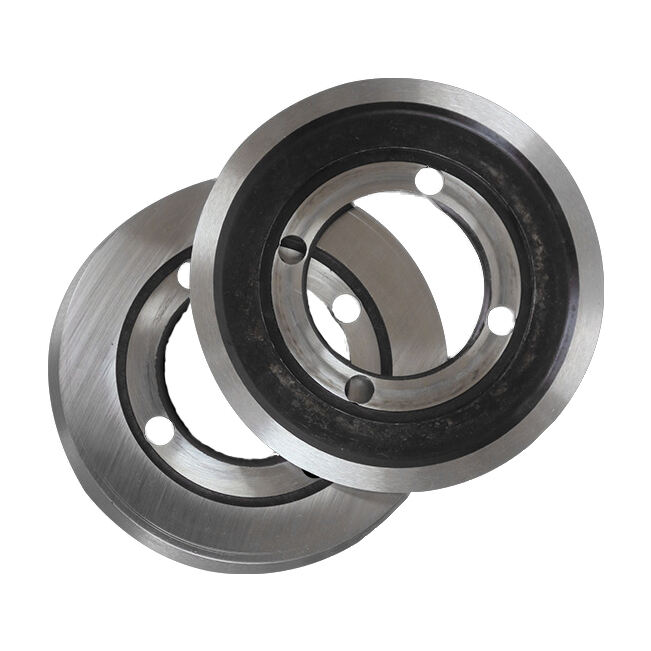

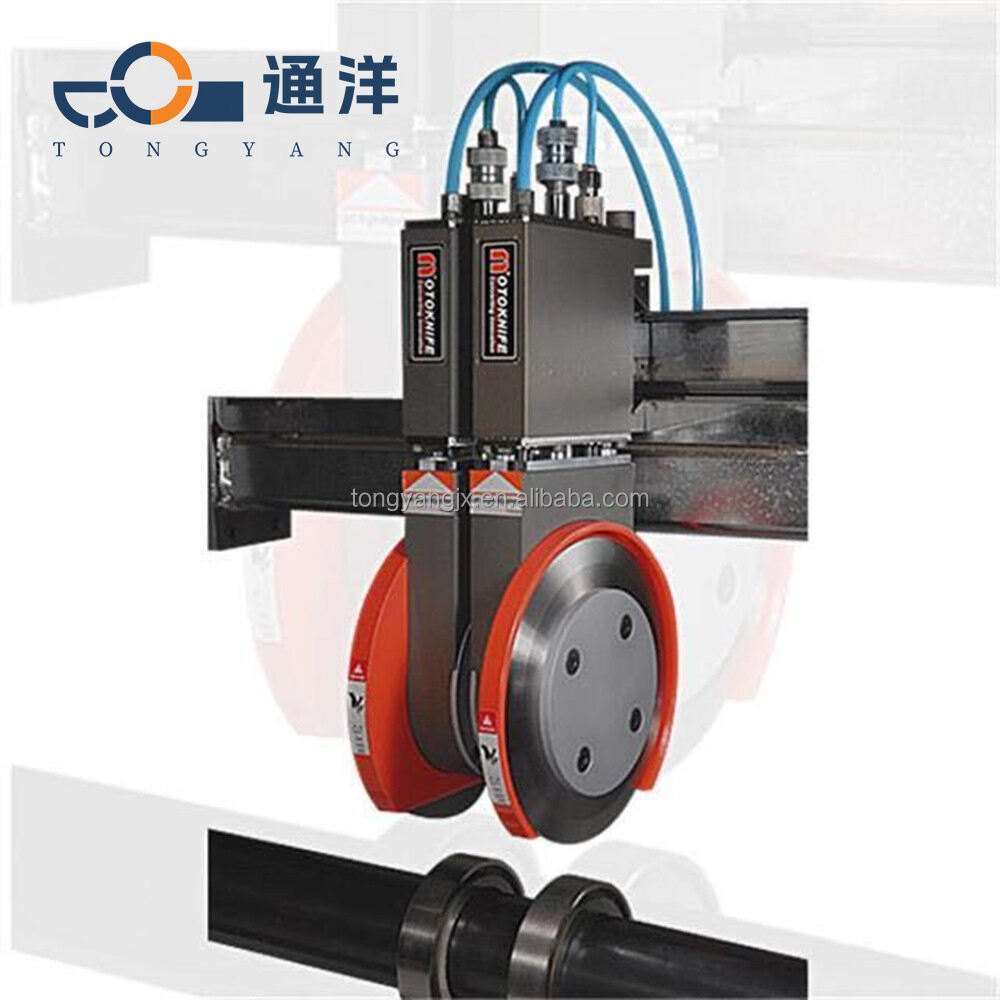

Bowl-type slitting blades are commonly used for slitting and trimming multi-layered and thickened leather. The selection of such blades needs to precisely match the material and specifications of the blades according to the material characteristics of the leather to be cut, such as hardness, thickness, and flexibility, so as to ensure cutting efficiency and edge quality.

- Overview

- Recommended Products

Materials and Their Applications

Titanium alloy

Material characteristics:In the cutting machine, the titanium alloy knife is relatively light in weight.At the same time, its high strength makes it less likely to deform during the cutting process, and its corrosion resistance enables it to adapt to various working environments.

Application:It is often used for cutting natural leather, plastics, metal casings, etc., and can accurately cut materials. Besides, it has good hygienic properties.

High carbon steel

Material characteristics:After professional heat treatment, high carbon steel can obtain very high hardness and strength, endowing the cutting tool with excellent cutting performance. It can cut materials quickly and accurately, and the cutting surface is relatively smooth. At the same time, it has good economic efficiency.

Application:It is widely applied in fields where the requirements for material cutting precision and tool performance are not particularly high, such as the edge trimming of inexpensive artificial leather, thin cardboard, and simple plastic films.

Alloy steel

Material characteristics:Alloy steel has relatively high hardness and strength, which can ensure the sharpness and durability of cutting. It also has good toughness, making it less likely to experience edge chipping or breakage during the cutting process. Additionally, it can adapt to the cutting of materials with different materials and thicknesses.

Application:It is suitable for cutting some materials with relatively high hardness or large thickness, such as multi-layer leather, rubber, thick paper, etc., and is widely used in industries such as leather processing and rubber product manufacturing.

High-speed steel

Material characteristics:In a high-speed rotating cutting machine, it can maintain good cutting performance at high temperatures and is not likely to have its cutting performance reduced due to heat generation. Its cutting edge maintains good sharpness, allowing for continuous cutting over a long period of time, reducing the frequency of sharpening and improving production efficiency.

Application:In industries such as automotive parts manufacturing, it is used for the edge trimming of materials like thin metal sheets, automotive interiors, plastic sheets, etc. It is also applied in some paper processing industries with high requirements, such as the edge trimming of high-end packaging paper and specialty paper.

Material customization

We also provide customization services for other materials

For each piece of custom-made product, the material inspection will be completed by a spectrometer during the factory shipment process.

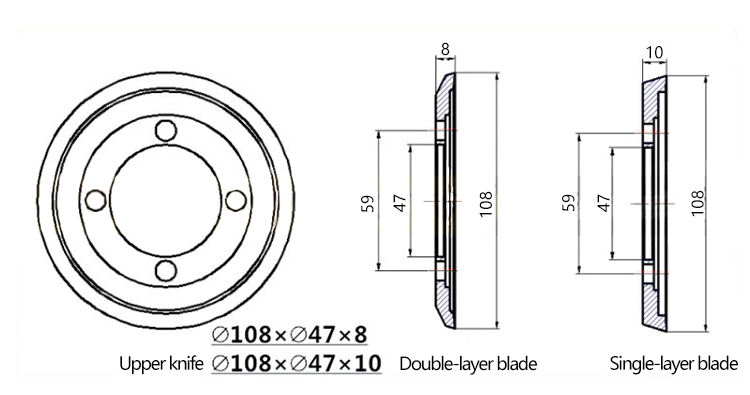

Common specifications

| Diameter | Inner diameter | Thickness |

| 135mm | 75mm | 17.5mm |

| 130mm | 60mm | 17.5mm |

| 108mm | 47mm | 20mm |

| 108mm | 47mm | 8mm |

| 108mm | 47mm | 10mm |

| 62mm | 22mm | 8mm |

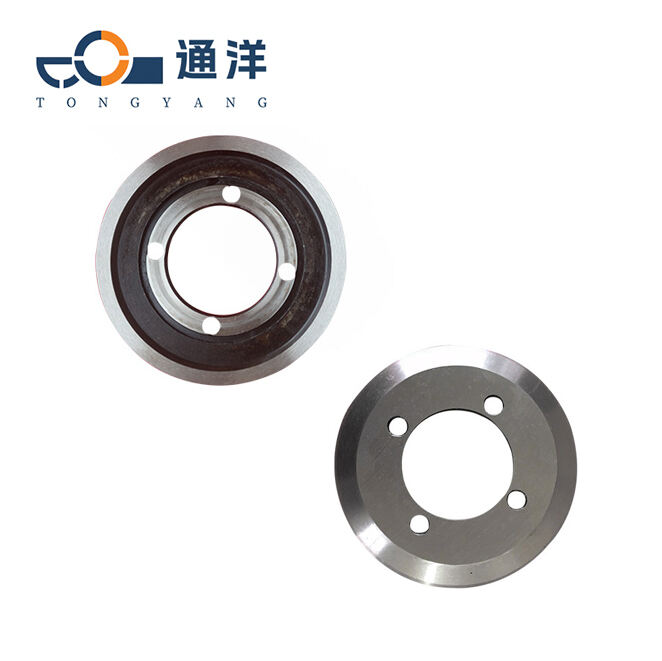

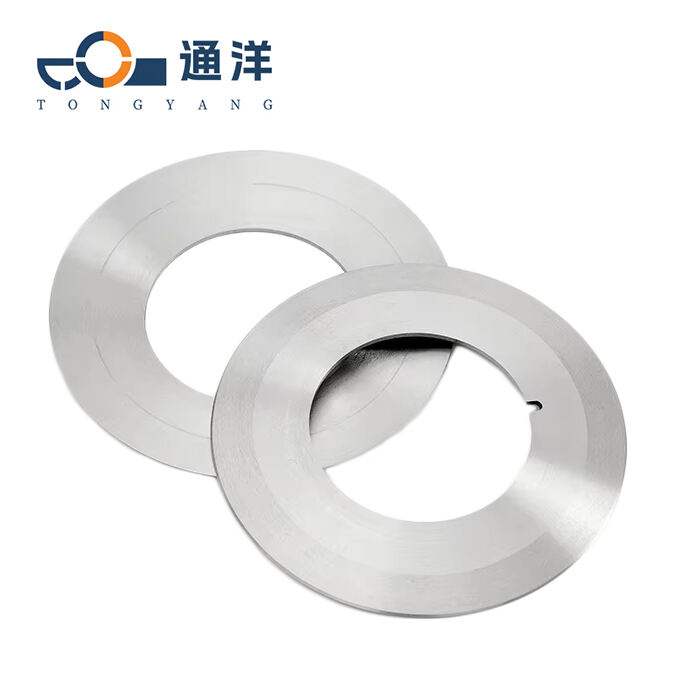

Upper and lower bowl - shaped knives: Differences between single - layer blades and double - layer blades

Cutting performance

Cut - in ability: An additional bevel on the double - layer blade enables it to cut into the material at a sharper angle. The double - layer blade can more easily cut through the surface of the material, with relatively less cut - in resistance. In contrast, the single - layer blade has a relatively single cut - in angle, and may encounter slightly greater difficulty when cutting into materials of the same hardness.

Cutting efficiency: Since the double-layer blade has two bevel edges participating in the cutting process, its cutting efficiency is relatively high during the cutting stroke. In contrast, the single-layer blade has only one cutting edge in operation, so its cutting efficiency is lower than that of the double layer blade.

Cutting quality

Flatness of the cutting edge: The two bevel edges of the double-layer blade work in coordination, resulting in balanced cutting force and a flatter cutting edge. In the case of a single-layer blade, if it is worn out or the operation is improper, burrs are likely to appear on the cutting edge.

Burr control: For materials prone to burrs, such as leather, the additional bevel edge of the double layer blade can, to a certain extent, perform secondary cutting on the burrs, reducing the generation of burrs. The single-layer blade is relatively weaker in burr control and may require subsequent edge trimming treatment. The double-layer blade is more suitable for precision machining fields with high requirements, and it is cost is also relatively high. The single-layer blade can cut some soft materials with not particularly high precision requirements, and its cost is relatively low.

Our advantages

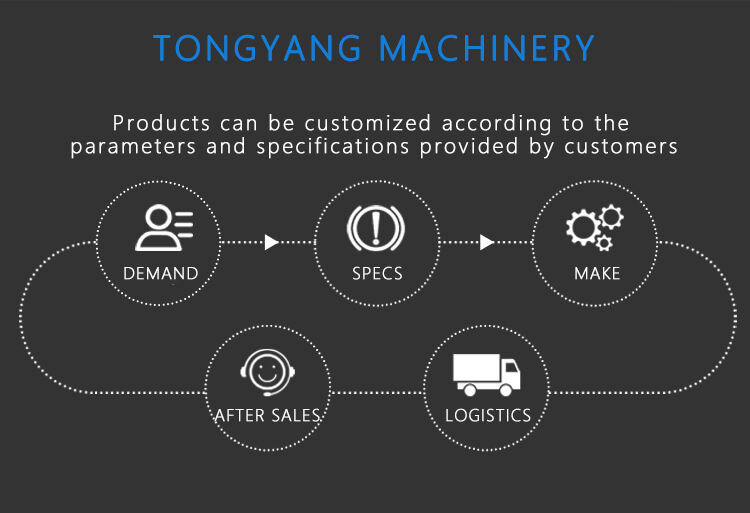

Customize

Precise Specification Adherence: Our experienced engineers and technicians are proficient in handling various specification requirements. Once your requirements are clear, we ensure that every parameter, from the dimensions of components to the performance indicators of the entire machine,is strictly adhered to. This precision guarantees that the final customized product not only meets but often exceeds your expectations.

Efficient Production Execution: Equipped with advanced manufacturing equipment and streamlined production processes, we can promptly transform the approved specifications into high - quality products. The optimized production workflow minimizes delays, ensuring that you receive your customized machinery within the promised time frame.

Comprehensive After - sales Support: Our service commitment extends beyond delivery. Our after sales team is always ready to assist you. Whether it's maintenance guidance, spare parts supply, or troubleshooting, we provide prompt and effective support to ensure the long - term smooth operation of your customized equipment.

Reliable Logistics Assurance: We ensure that your customized products are carefully packaged and safely transported to the designated location. Timely tracking and communication during the logistics process keep you informed of every step of the progress.

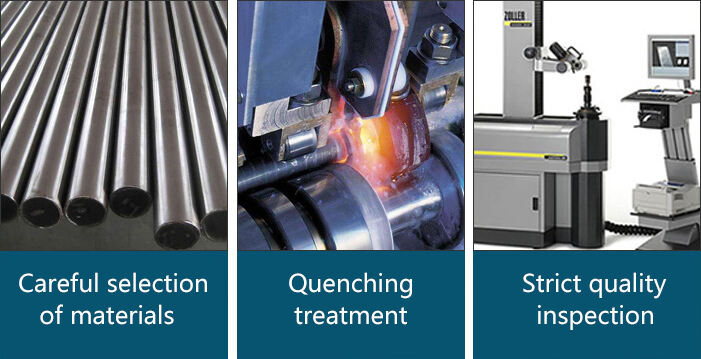

Quality inspection

From material selection, production to quality inspection, we strictly follow the Standard Operating Procedure (SOP). In the material selection process, we have in-depth cooperation with top suppliers in the industry and carefully select high-purity and high-performance raw materials such as high-quality steel and cemented carbide to ensure that every industrial blade has excellent hardness, wear resistance, and red hardness from the source. During the production process, we use numerically controlled precision machining equipment and cutting edge manufacturing processes, implementing precision requirements throughout every single procedure. Whether it is the edge grinding of the blade, heat treatment strengthening, or the shaping of the overall structure, we strive for perfection. In the quality inspection stage, we adopt a multi-dimensional inspection system, covering dozens of strict indicators such as hardness testing, sharpness inspection, wear resistance simulation, and dimensional accuracy calibration. Through the dual verification of professional instruments and manual rechecking, we prevent any defective products from entering the market.