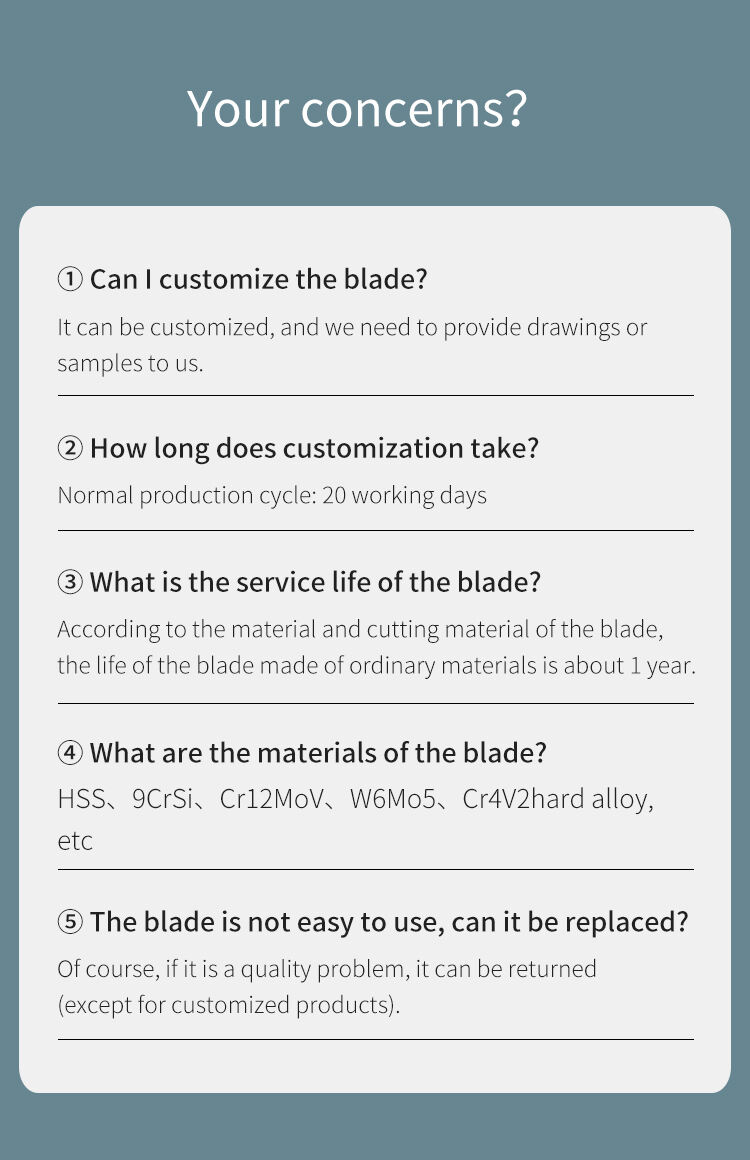

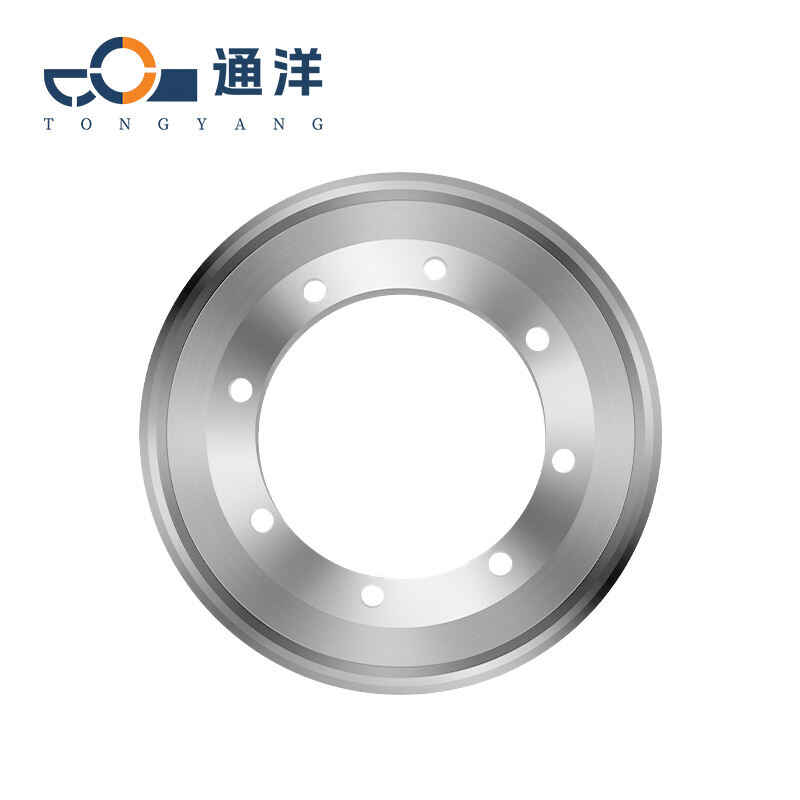

Paper slitting knife

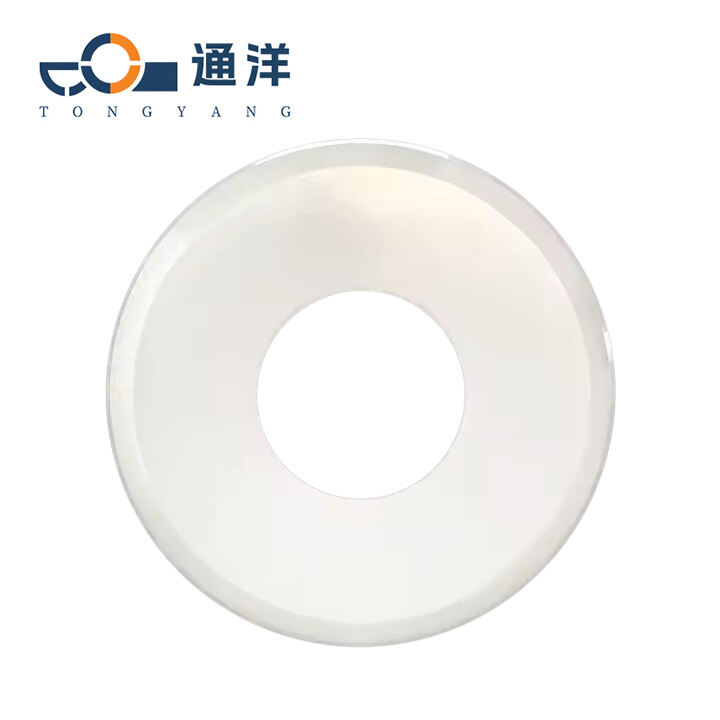

It can slit various plastic films, such as polyethylene (PE) film, polypropylene (PP) film, polyvinyl chloride (PVC) film, etc., to meet the requirements for the dimensions and specifications of plastic films in different fields such as packaging, agriculture, and electronics.

- Overview

- Recommended Products

Common materials and applications

Alloy tool steel

Material characteristics:Alloy tool steel has multiple alloying elements added to it, such as chromium, molybdenum, vanadium, etc., and it has good hardenability and wear resistance. After professional heat treatment, its hardness can reach around HRC60-65. It can withstand a certain degree of impact load and is not prone to edge chipping and edge curling phenomena during the processes of slitting paper, paper tubes, and fabrics. Its cost is relatively moderate, and it has a high cost-performance ratio, making its suitable for large-scale production and application.

Application:For general writing paper, office paper, paper tubes, fabrics, etc., the upper and lower slitting knives made of alloy tool steel are usually used. The slitting requirements for these materials are relatively low, and the alloy tool steel slitting knives can meet the requirements for production efficiency and quality, which can reduce the production cost.

High-speed steel

Material characteristics:It can meet the requirements of high-speed cutting and automated slitting equipment, maintain relatively high hardness and cutting performanceeven at high temperatures, reduce the wear and replacement frequency of cutting tools,and improve production efficiency.

Application:The upper and lower slitting knives made of high-speed steel are often used in situations where high requirements are placed on slitting accuracy and speed, such as in the printing industry for slitting printed paper, as well as for paper tubes, non-woven fabrics plastic films, etc. The high-speed steel paper slitting knives can maintain good edge sharpness and dimensional accuracy during the high-speed slitting process, ensuring that the edges of the slit paper are neat and smooth, thus meeting the quality requirements of high-precision slitting.

Cemented carbide

Material characteristics:It is mainly composed of hard phases such as tungsten carbide and titanium carbide, and bonding phases such as cobalt and nickel. It has extremely high hardness, which can reach HRA90-93 (equivalent to HRC74-81), and has excellent wear resistance, corrosion resistance and high-temperature resistance. However, it has poor toughness, high brittleness, weak ability to withstand impact loads, and is expensive.

Application:For special papers with coatings, films, or those that are hard and wear-resistant, the upper and lower slitting knives made of cemented carbide are the first choice. Their high hardness and wear resistance can effectively resist wear and ensure the slitting quality and the service life of the knives.

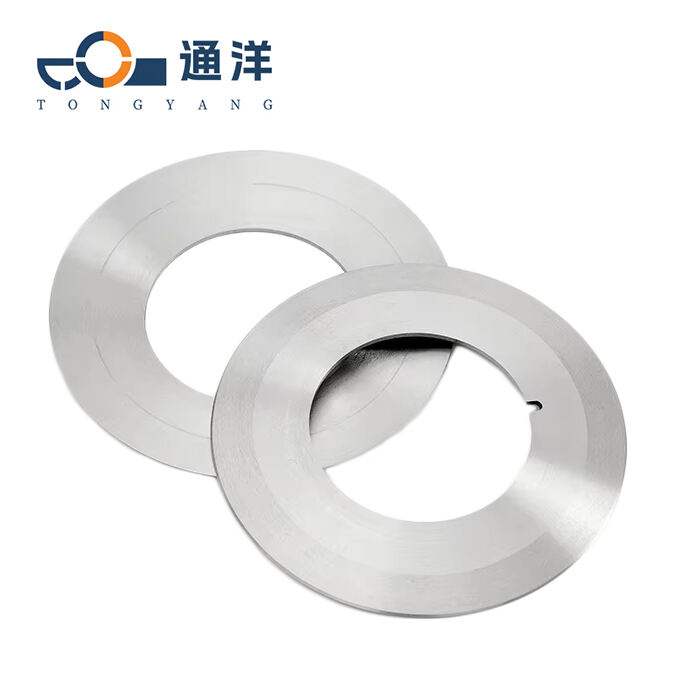

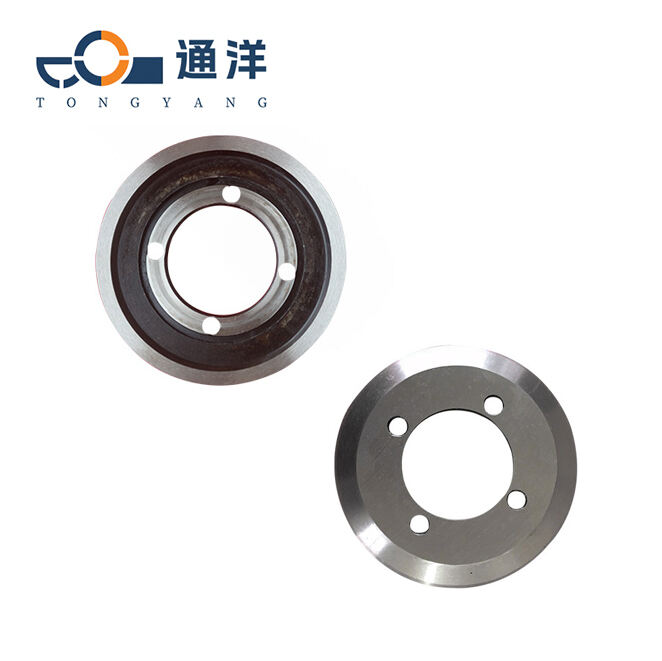

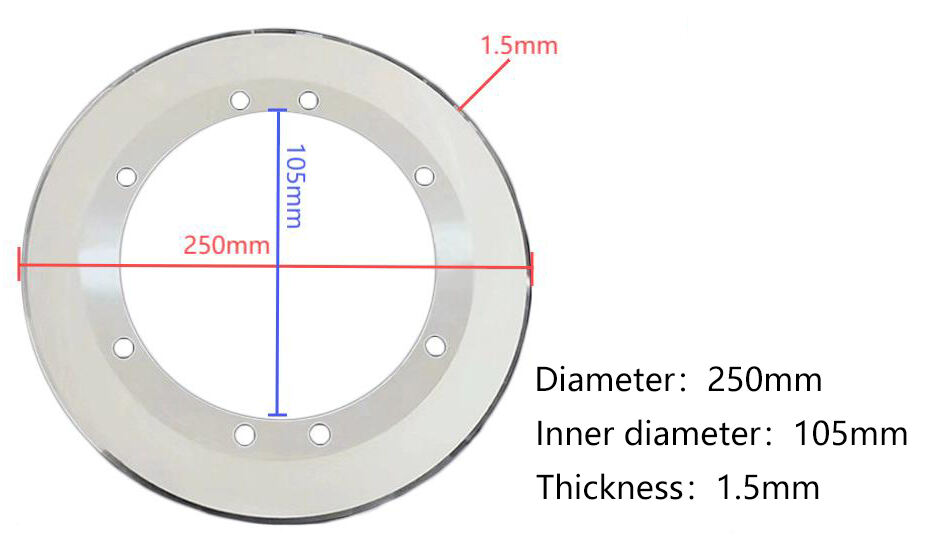

Common specifications

| Specifications(mm) | Outer diameter(mm) | Inner diameter(mm) | Thickness(mm) |

| Φ61×Φ41×1 | 61 | 41 | 1 |

| Φ68×Φ40×1 | 68 | 40 | 1 |

| Φ68×Φ46×0.5 | 68 | 46 | 0.5 |

| Φ70×Φ40×1 | 70 | 40 | 1 |

| Φ75×Φ45×1 | 75 | 45 | 1 |

| Φ90×Φ60×1.2 | 90 | 60 | 1.2 |

| Φ100×Φ75×1 | 100 | 75 | 1 |

| Φ105×Φ66×1.2 | 105 | 66 | 1.2 |

| Φ105×Φ70×1.2 | 105 | 70 | 1.2 |

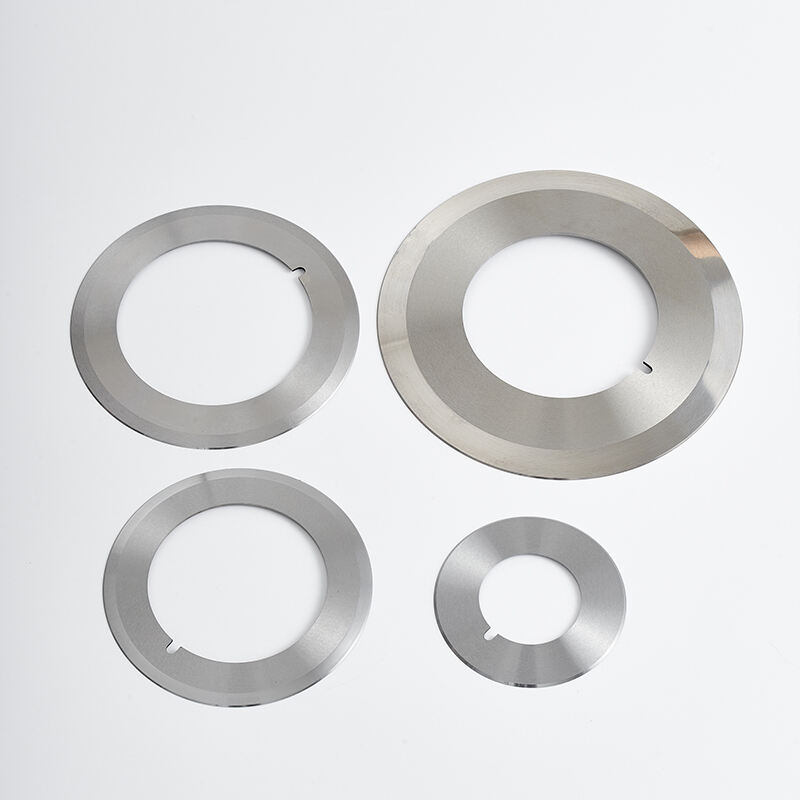

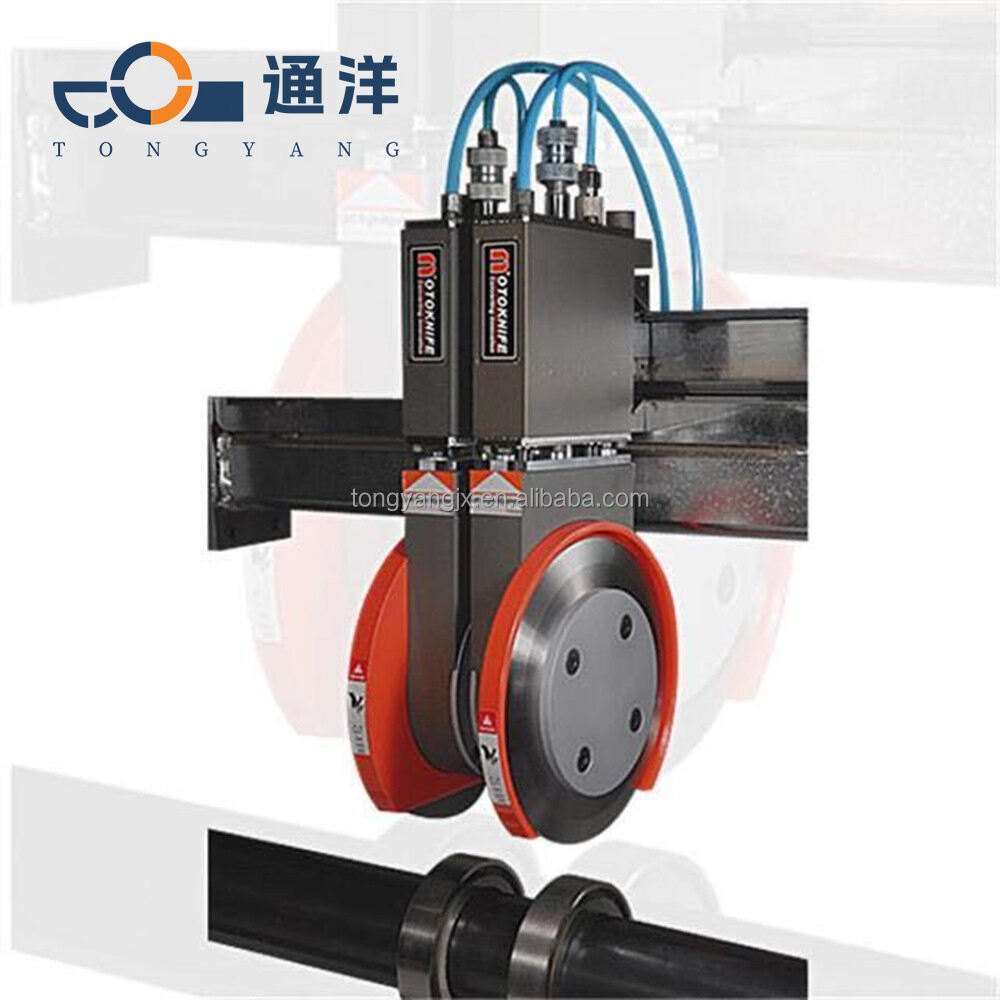

The process and precautions for customizing other specifications

During the customization process, it is of vital importance to accurately measure whether the slitting machine has any openings (if applicable) and the width of the cutter shaft. This can ensure that the customized components fit perfectly, enabling seamless operation and preventing potential malfunctions or inefficiencies that may be caused by improper fitting of the components.

Our advantages

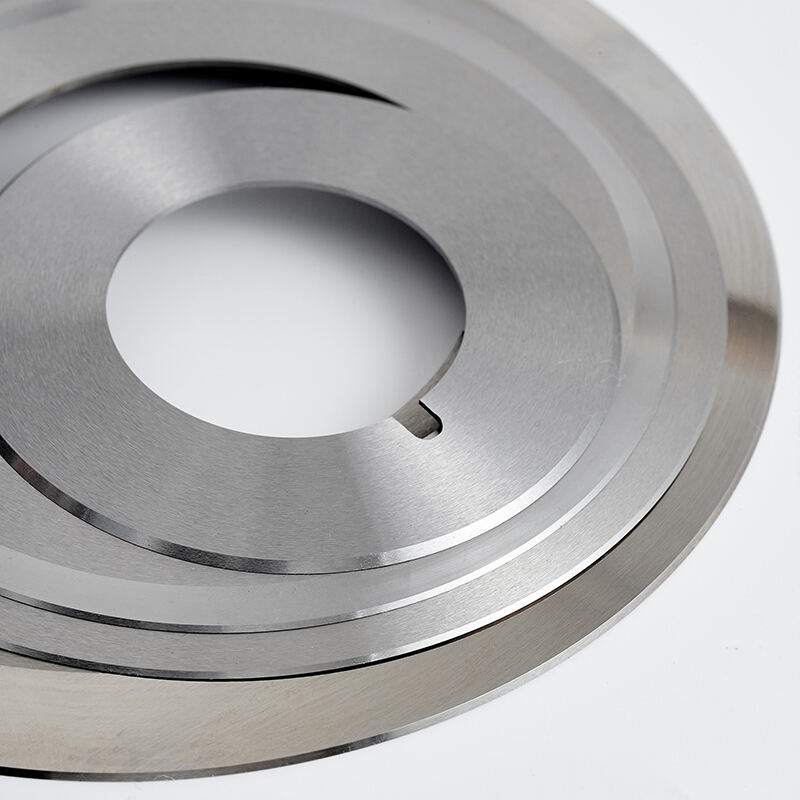

From material selection, production to quality inspection, we strictly follow the Standard Operating Procedure (SOP). In the material selection process, we have in-depth cooperation with top suppliers in the industry and carefully select high-purity and high-performance raw materials such as high-quality steel and cemented carbide to ensure that every industrial blade has excellent hardness, wear resistance, and red hardness from the source.During the production process, we use numerically controlled precision machining equipment and cutting edge manufacturing processes, implementing precision requirements throughout every single procedure. Whether it is the edge grinding of the blade, heat treatment strengthening, or the shaping of the overall structure, we strive for perfection. In the quality inspection stage, we adopt a multi-dimensional inspection system, covering dozens of strict indicators such as hardness testing, sharpness inspection, wear resistance simulation, and dimensional accuracy calibration.Through the dual verification of professional instruments and manual rechecking, we prevent any defective products from entering the market.