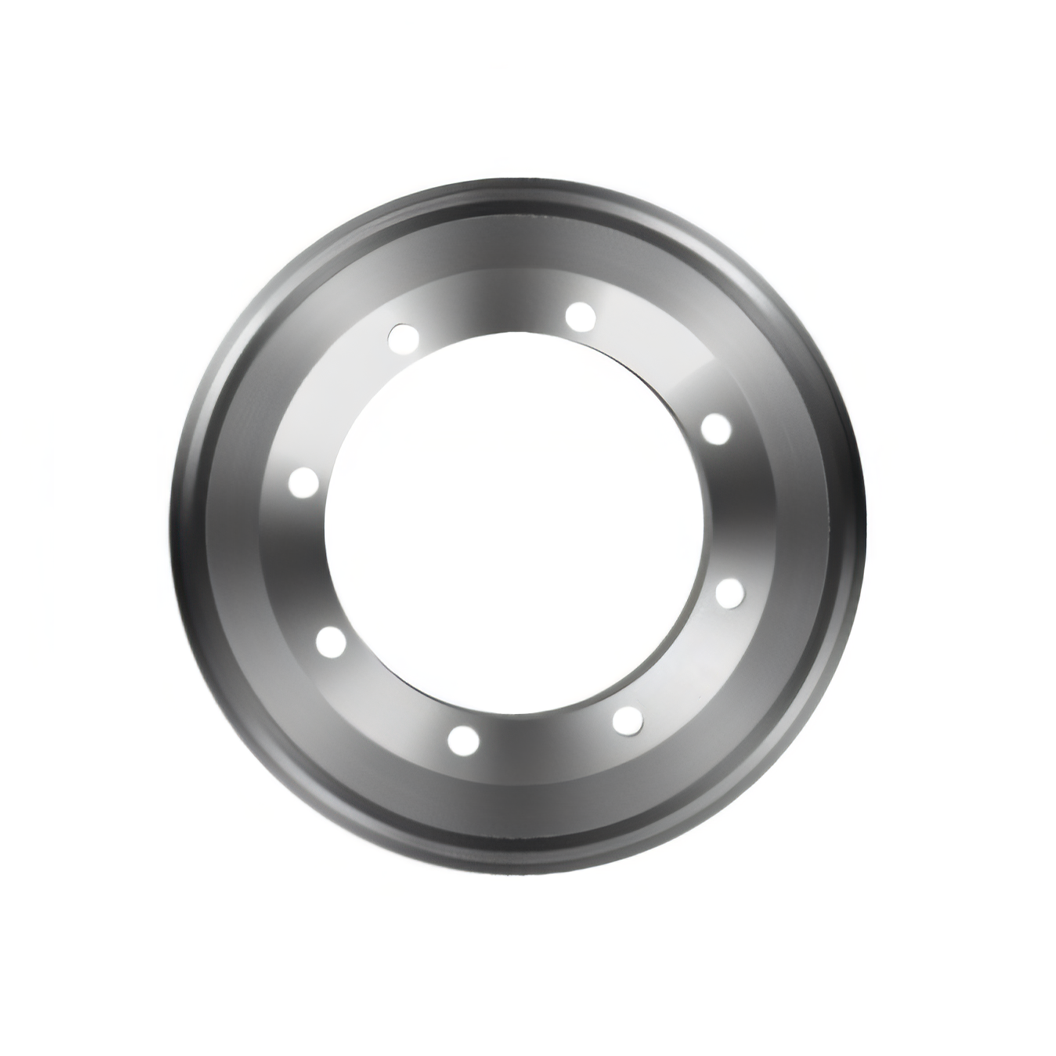

Rubber cutting knife

Rubber cutting blades, as key tools for rubber product processing, have their performance and quality directly affecting the production efficiency and product quality of rubber products. Reasonably selecting and using rubber cutting blades according to different materials to be cut is of great significance for improving the processing level of rubber products.

- Overview

- Recommended Products

Common materials and applications

High-speed steel

Material characteristics:Hardness, wear resistance and material strength enable it to maintain excellent cutting performance even during high-speed cutting, and it has a certain degree of toughness, making it less likely to have chipping.

Application:It is used for cutting rubber materials of various hardness levels, including natural rubber, synthetic rubber, etc. In the rubber product processing industry, it is commonly used for cutting products such as rubber tires, rubber sheets, and rubber tubes. It can achieve high-precision cutting, and the tool has a long service life which can reduce the processing cost.

Cemented carbide

Material characteristics:It has extremely high hardness, excellent wear resistance and heat resistance, and can withstand higher cutting temperatures and pressures. It has stable chemical properties and is not likely to undergo chemical reactions or adhere to rubber.

Application:In some situations where extremely high requirements are placed on cutting precision and surface quality, such as in the processing of rubber components in the automotive industry and other fields, it can ensure the smoothness and flatness of the cutting surface and improve product quality.

Material customization

We also provide customization services for other materials

For each customized product, the material inspection will be carried out by a spectrometer.

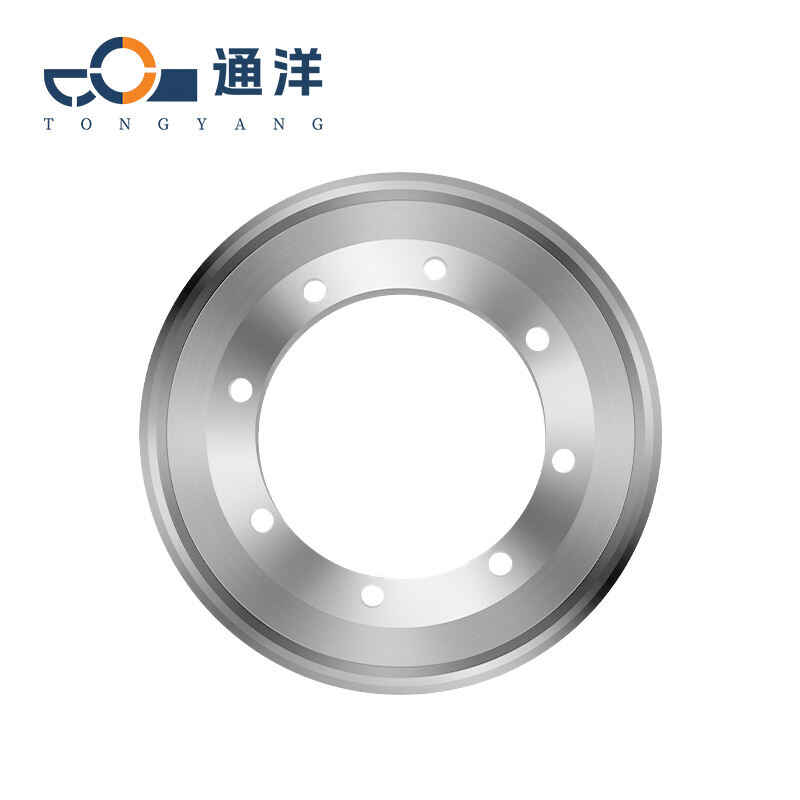

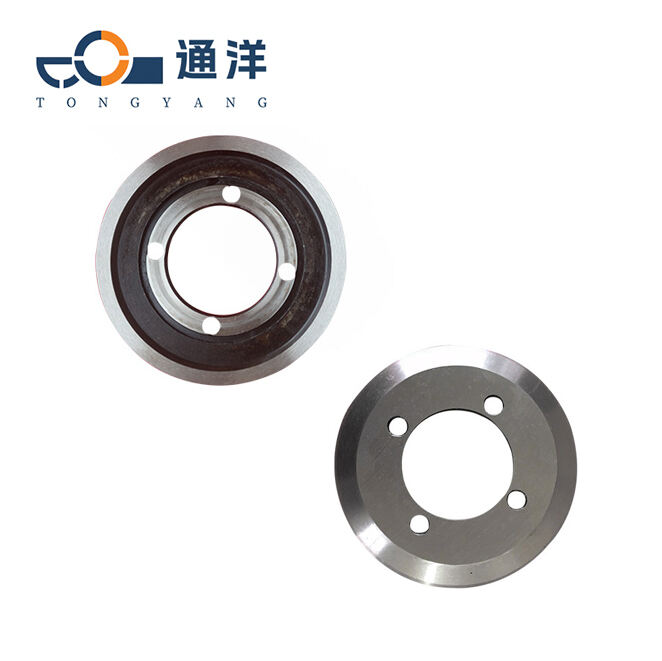

Common specifications

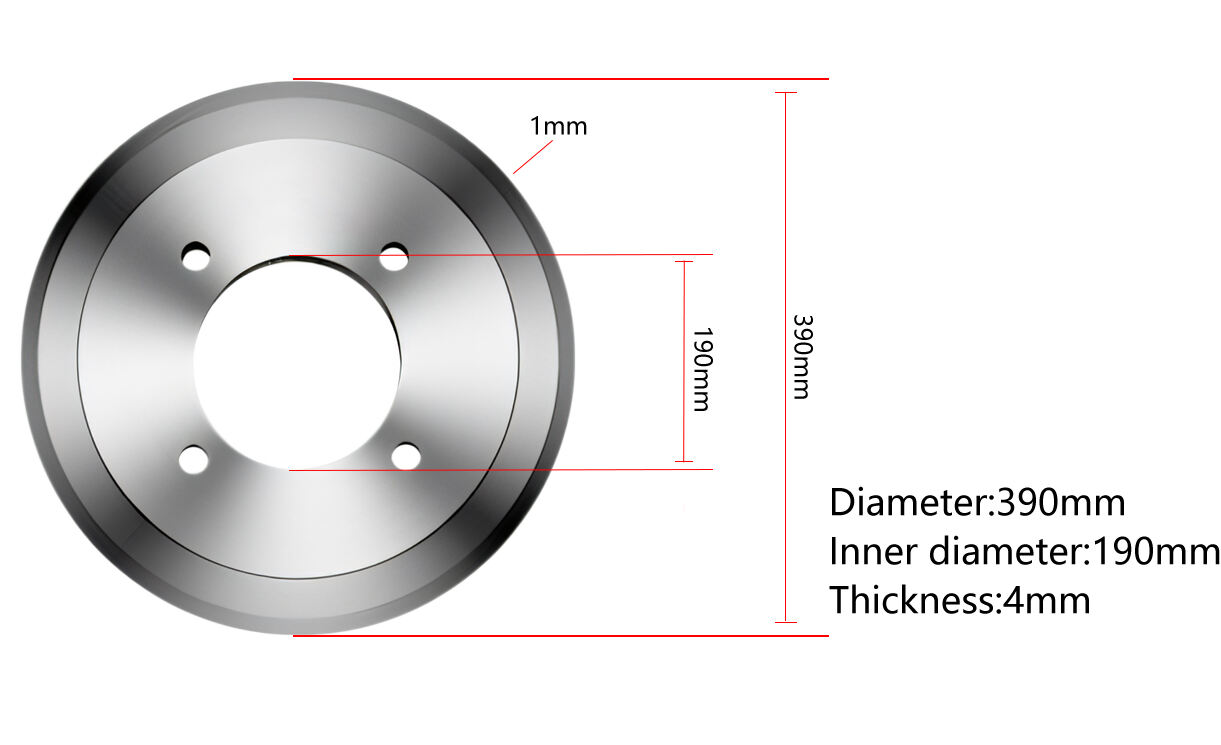

| Diameter | Inner diameter | Thickness | Application |

| 390mm | 190mm | 4mm | It is commonly used for the trimming treatment of rubber tires and relatively thick leather, as well as the production of small and medium-sized rubber products. |

| 420mm | 190mm | 6mm | The increased diameter and thickness can enable high-speed shearing of multi-layer rubber products. |

| 450mm | 200mm | 6mm | A larger diameter can be used to cut natural rubber, and it is not easy for the natural rubber to stick to the cutting machine. |

| 480mm | 225mm | 10mm | With a thickness of 10mm, it can easily cut scrap tires and is widely used in the rubber recycling industry. |

When customizing, it is necessary to provide the drawings or specific parameters of the cutting tool Please measure the specifications that are suitable for the mechanical blade before customization(Parameters such as diameter, inner diameter, thickness, and punching)

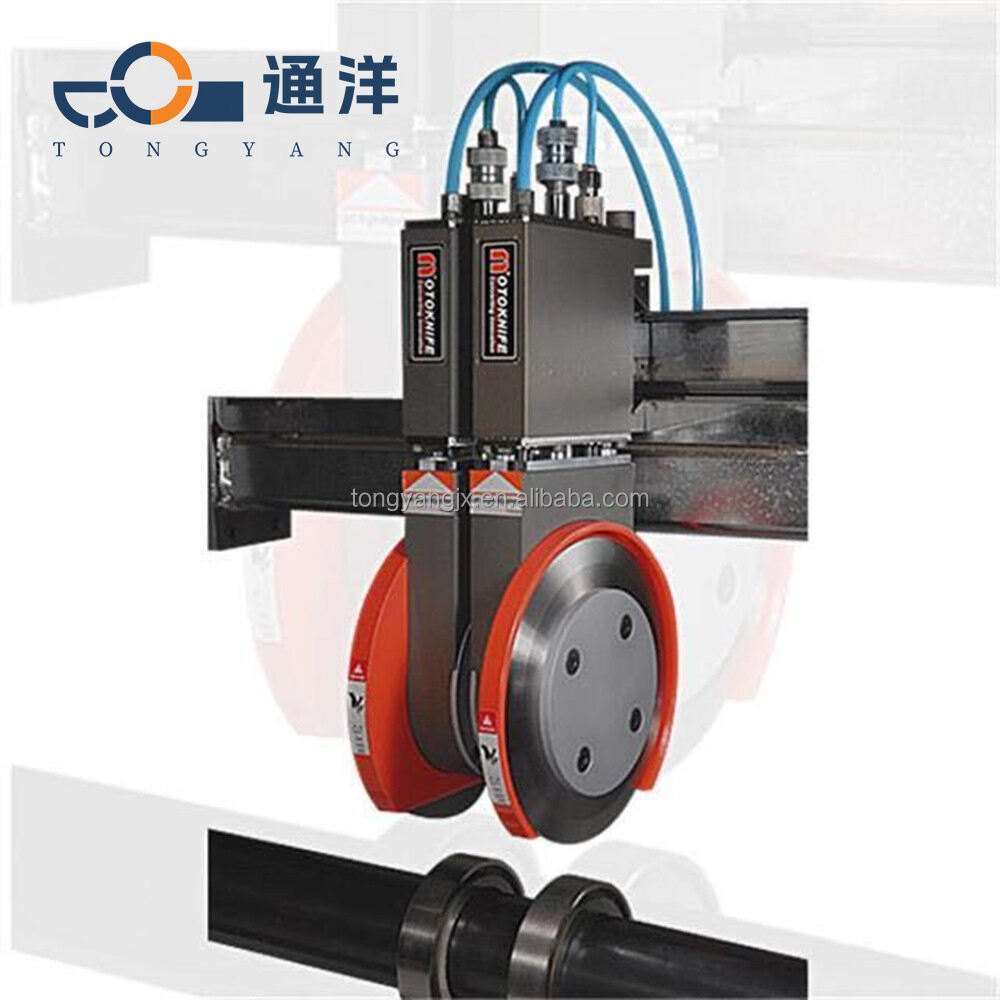

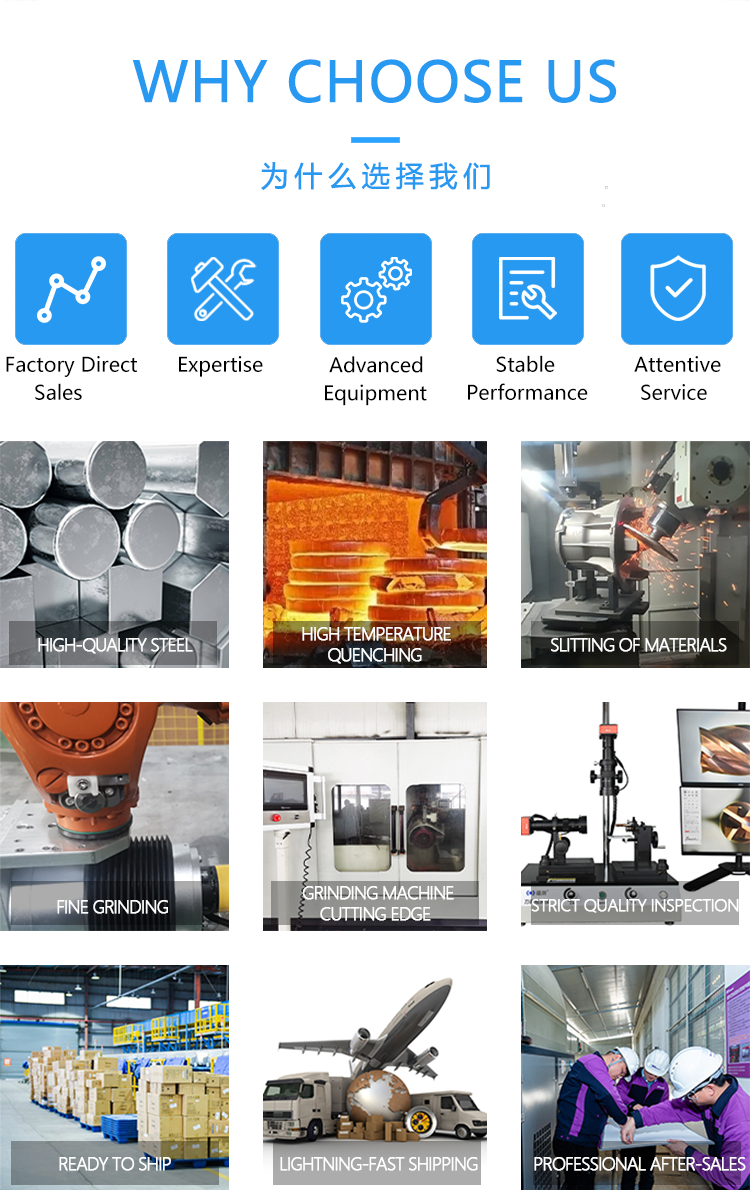

Our advantages

The cutting tools we produce are compatible with various types of slitting machines on the market. All of them have passed strict on-machine tests, ensuring stable and efficient operation. Whether it is the slitting of materials such as adhesive tapes, non-woven fabrics, rubber products, or toilet paper rolls, precise and smooth cutting can be achieved, providing a reliable guarantee for your production and processing. Reliable Logistics Assurance: We ensure that your customized products are carefully packaged and safely transported to the designated location. Timely tracking and communication during the logistics process keep you informed of every step of the progress.