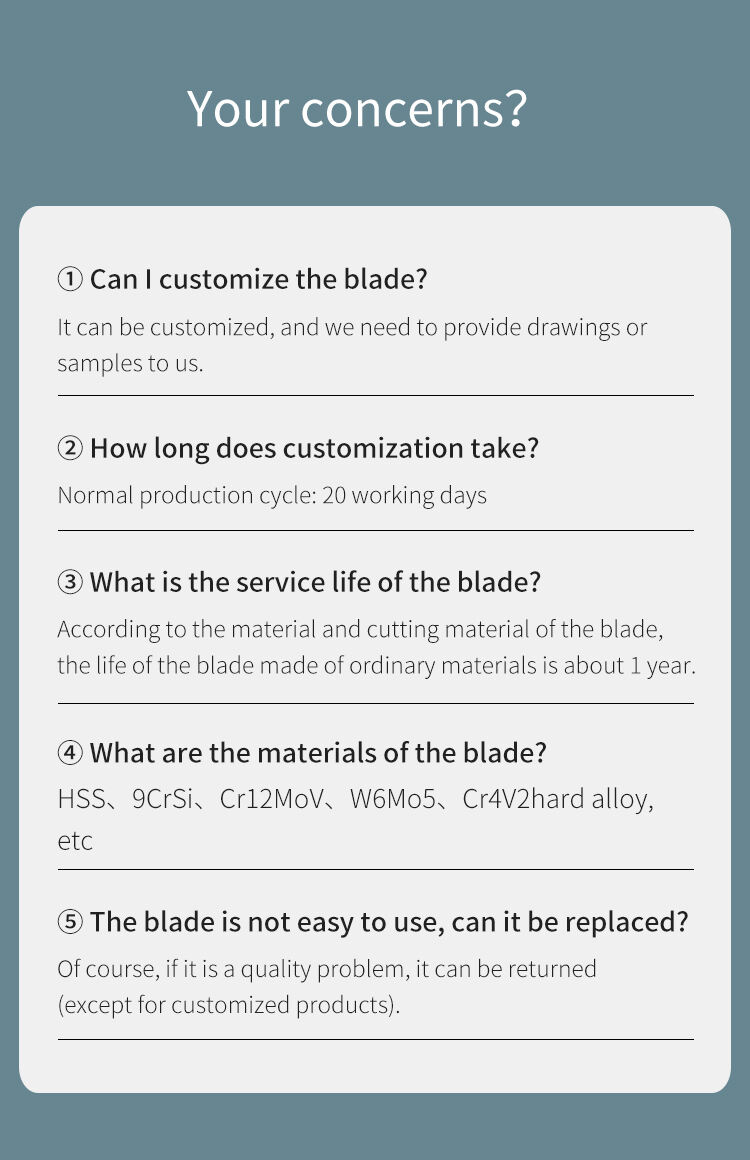

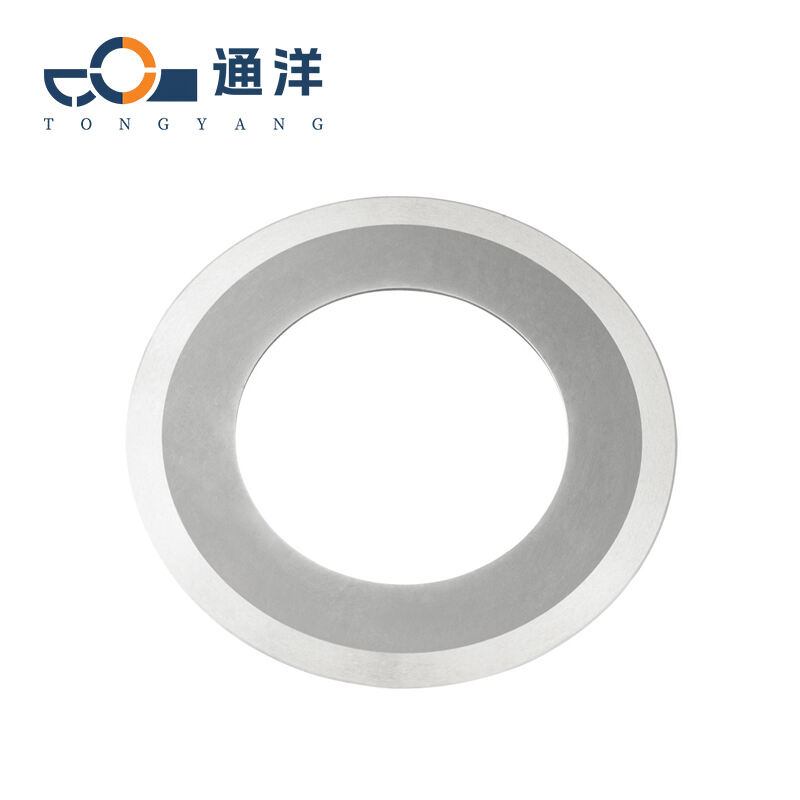

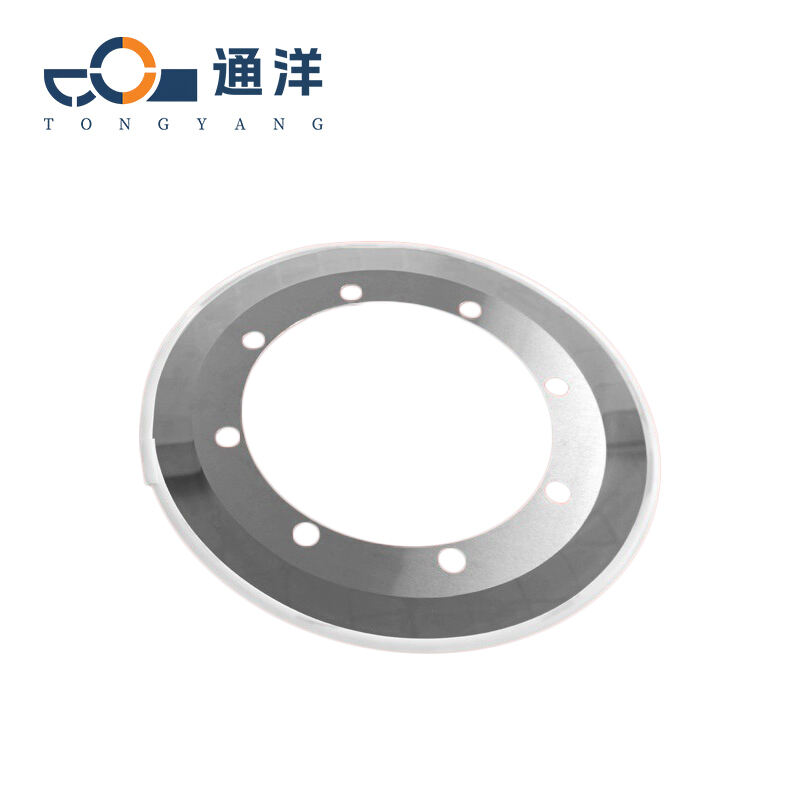

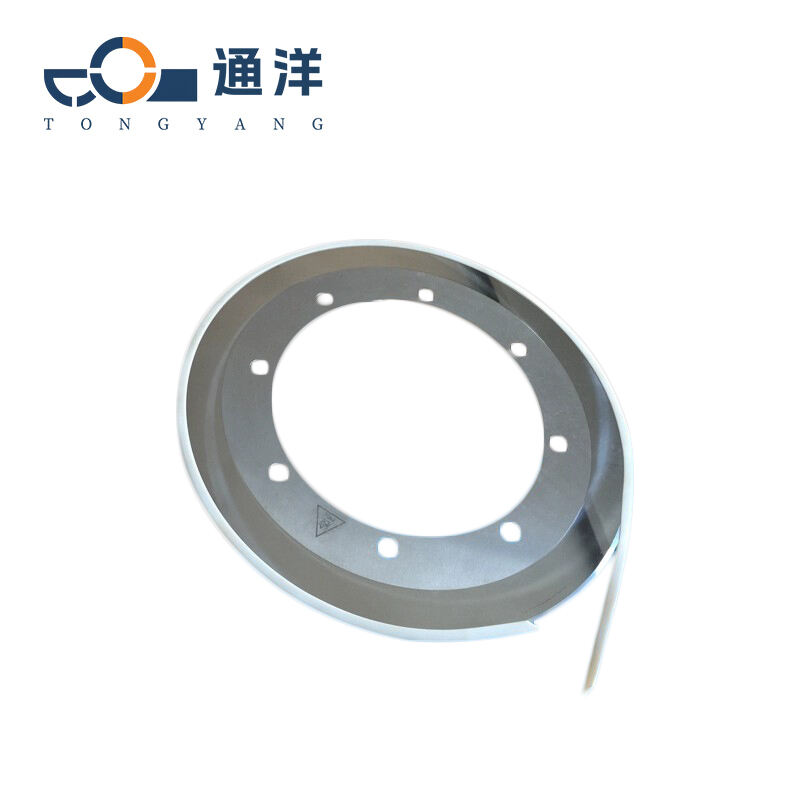

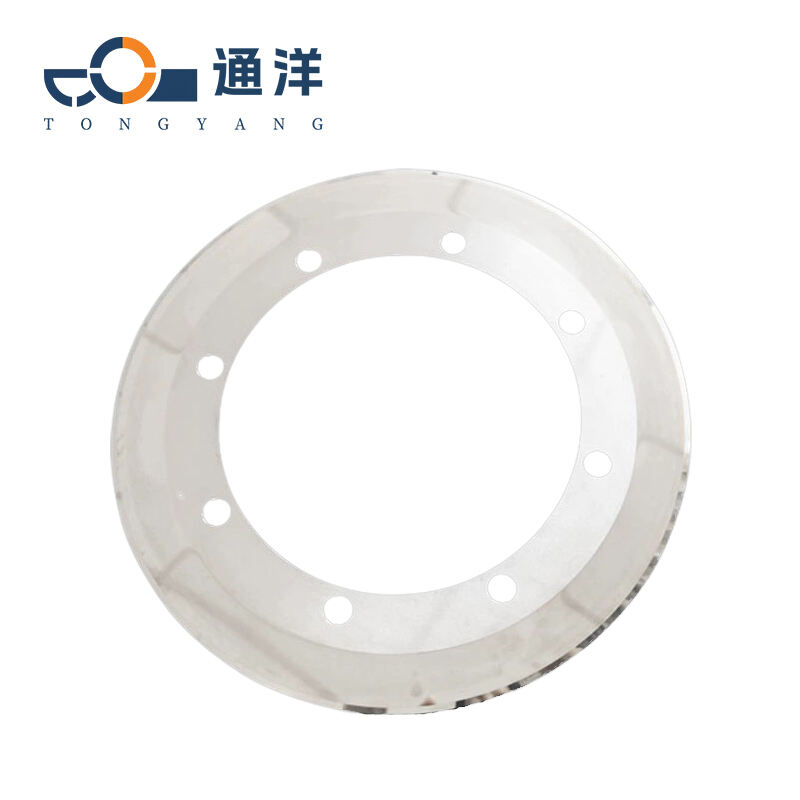

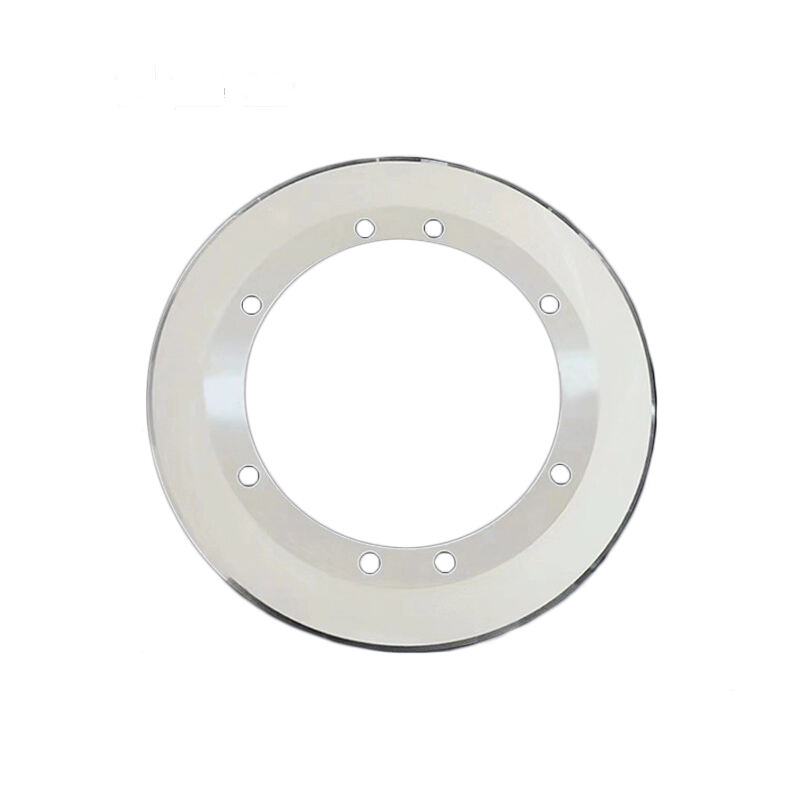

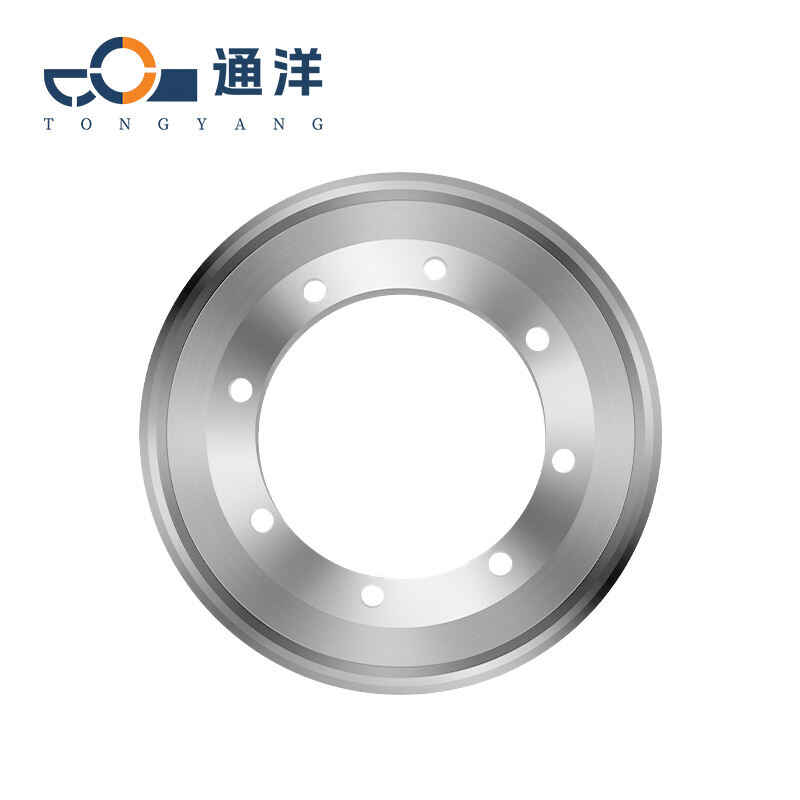

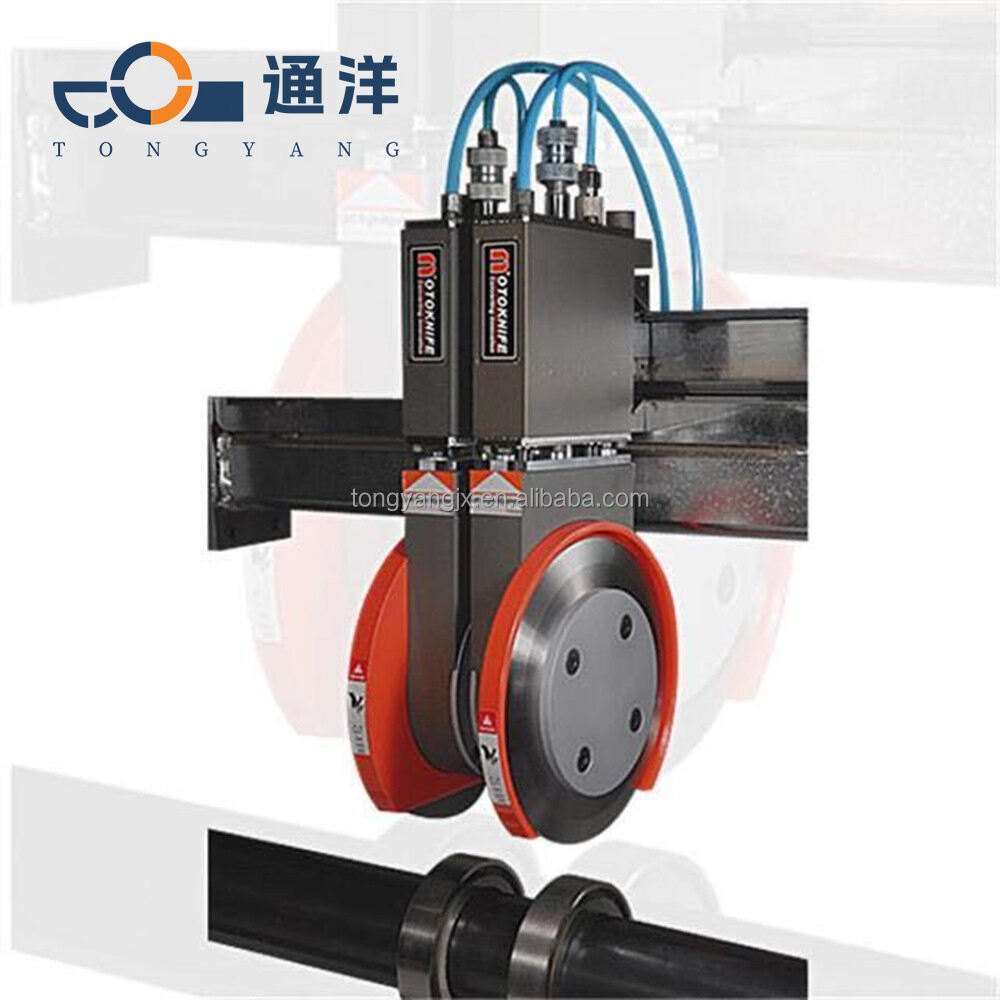

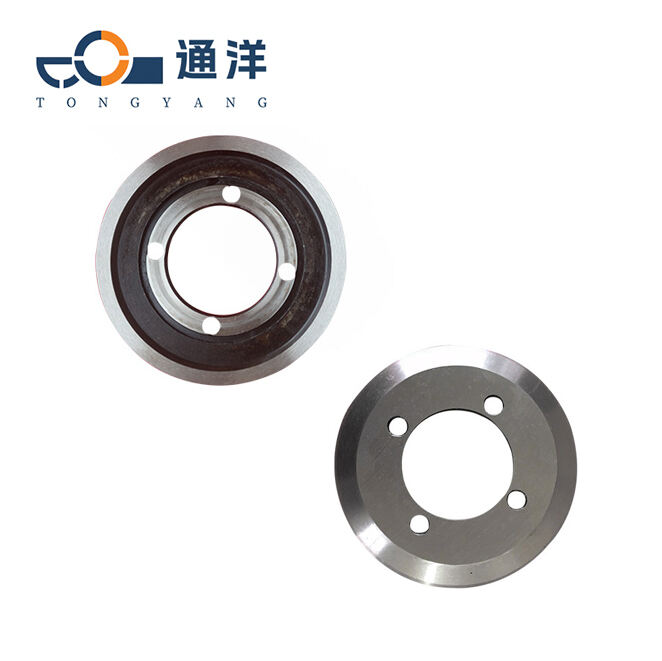

Thin Cardboard Slitting Knife

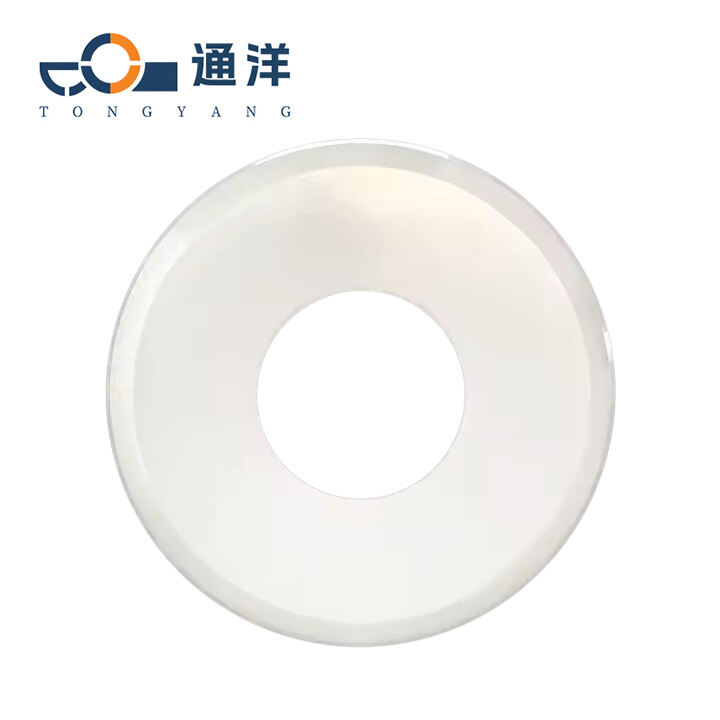

This type of circular blade can meet the cutting needs of different corrugated boards, and the specific blade materials and specifications can also be replaced and customized according to different cutting materials.

- Overview

- Recommended Products

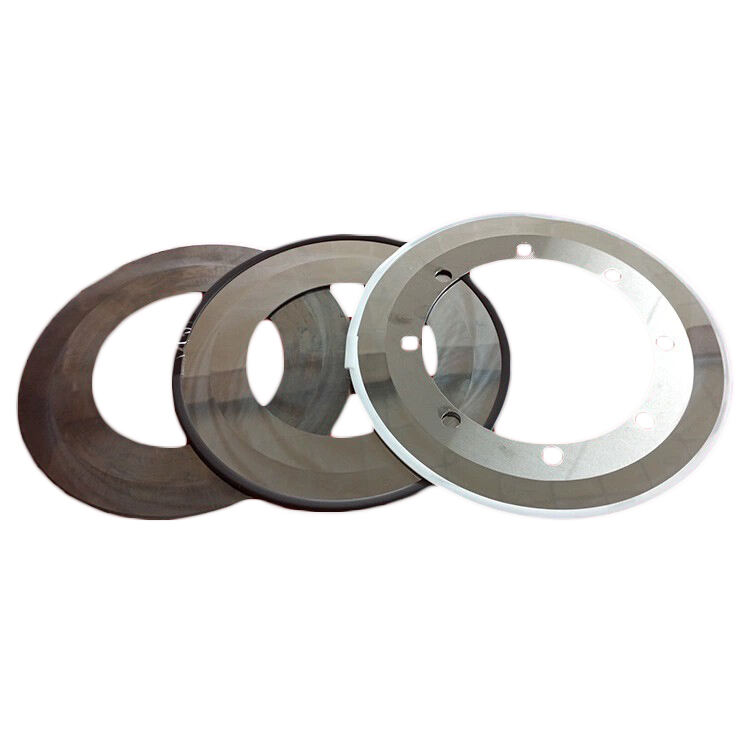

Materials and Their Applications

High-speed steel

Material characteristics:It has high hardness, high wear resistance and good toughness, excellent red hardness, and can still maintain good cutting performance at high temperatures.

Application:It can adapt to corrugated cardboard and thin cardboard with various hardness levels. The cutting edge is sharp and durable, which can ensure the slitting quality, reduce burrs and damage at the edges of the cardboard. It is suitable for production scenarios where there are certain requirements for slitting accuracy and efficiency.

Cemented carbide

Material characteristics:It has extremely high hardness, excellent wear resistance and corrosion resistance, good thermal stability, and can withstand higher cutting speeds and pressures.

Application:When slitting corrugated cardboard and thin cardboard at high speed, it can maintain the dimensionalaccuracy and cutting performance of the tool. The edges of the slit cardboard are smooth, neat, and free of burrs.It is suitable for high-speed automated slitting production lines and scenarios with strict requirements for slitting quality.

Alloy steel

Material characteristics:By adding alloying elements, it has good strength, toughness and a certain degree of wear resistance, with excellent comprehensive performance.

Application:It can meet the requirements for slitting general corrugated cardboard and thin cardboard. While ensuring the slitting quality, it has a good cost-performance ratio. It is suitable for small-scale production and can save the cost of tool replacement.

Tungsten steel

Material characteristics:It has high hardness, high density, high wear resistance, and good compressive strength as well as strong chemical stability and corrosion resistance.

Application:It can withstand relatively large cutting forces, is not prone to deformation during the slitting process,and can be used to slit corrugated cardboard with relatively large thickness and high hardness. It can maintain a long-term and stable slitting effect and improve production efficiency.

Precautions for Customizing Tools of Other Materials

It is necessary to clarify the purpose of the cutting tool (such as cutting or slicing) and the characteristics of the processing material (hardness, toughness, thickness, etc.). The requirements for the material of the cutting tool vary significantly when cutting cardboard, corrugated cardboard, and cartons of different qualities. At the same time, the processing accuracy should be taken into account. For high-precision processing, the cutting tool needs to have good dimensional stability and sharpness.

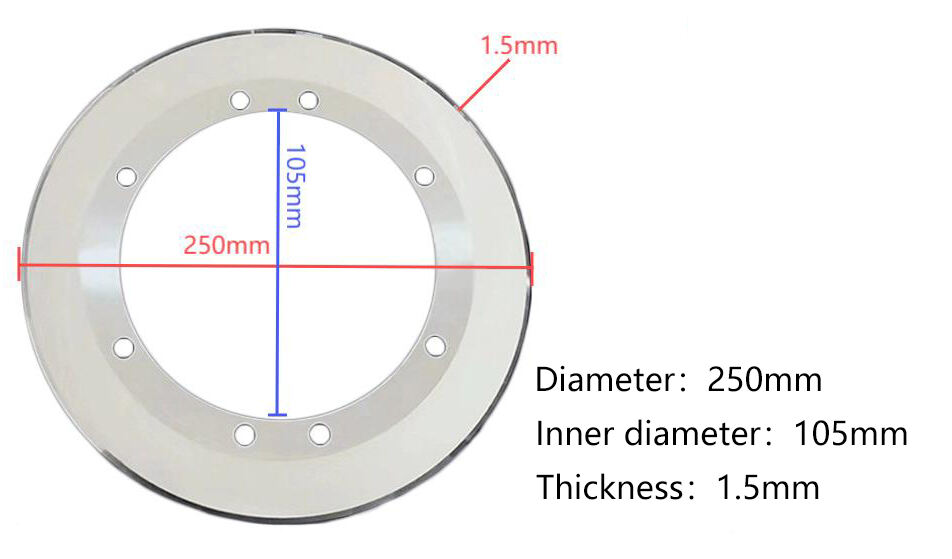

Common Specifications

| Diameter | Inner diameter | Thickness | Number of holes |

| 200mm | 122mm | 1.2mm | --- |

| 230mm | 110mm | 1.5mm | --- |

| 260mm | 140mm | 1.4mm | --- |

| 250mm | 105mm | 1.5mm | --- |

| 260mm | 158mm | 1.5mm | 8 |

| 260mm | 158mm | 1.4mm | --- |

| 270mm | 168mm | 1.5mm | 8 |

In addition to the common specifications, we can also provide customization services.

Precautions for Customization

When making a customization, attention should be paid to the specifications of the diameter and inner diameter. It shall be subject to the specific measurement in practice.

Our advantages

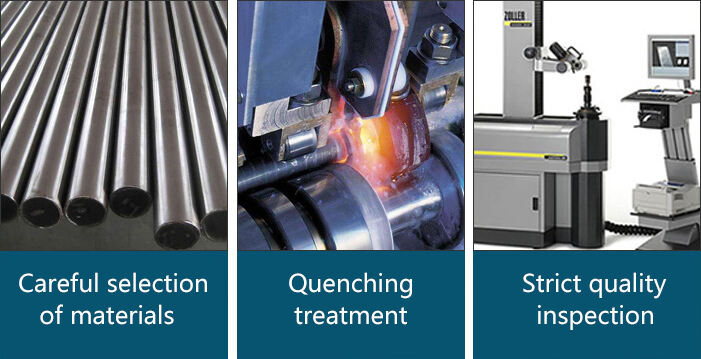

From material selection, production to quality inspection, we strictly follow the Standard Operating Procedure (SOP). In the material selection process, we have in-depth cooperation with top suppliers in the industry and carefully select high-purity and high-performance raw materials such as high-quality steel and cemented carbide to ensure that every industrial blade has excellent hardness, wear resistance,and red hardness from the source. During the production process, we use numerically controlled precision machining equipment and cutting edge manufacturing processes, implementing precision requirements throughout every single procedure. Whether it is the edge grinding of the blade, heat treatment strengthening, or the shaping of the overall structure, we strive for perfection. In the quality inspection stage, we adopt a multi-dimensional inspection system, covering dozens of strict indicators such as hardness testing, sharpness inspection, wear resistance simulation, and dimensional accuracy calibration. Through the dual verification of professional instruments and manual rechecking, we prevent any defective products from entering the market.

We always adhere to the concept of quality first and, with standardized and regulated processes, continuously provide customers with industrial blades that feature high precision, long service life, and stable performance, safeguarding our customers' efficient production.