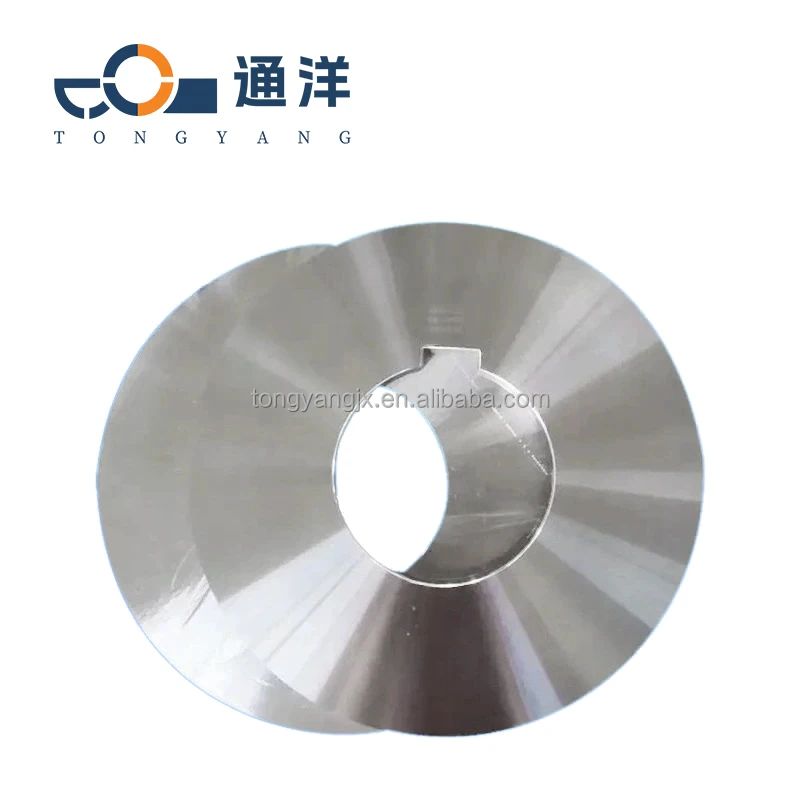

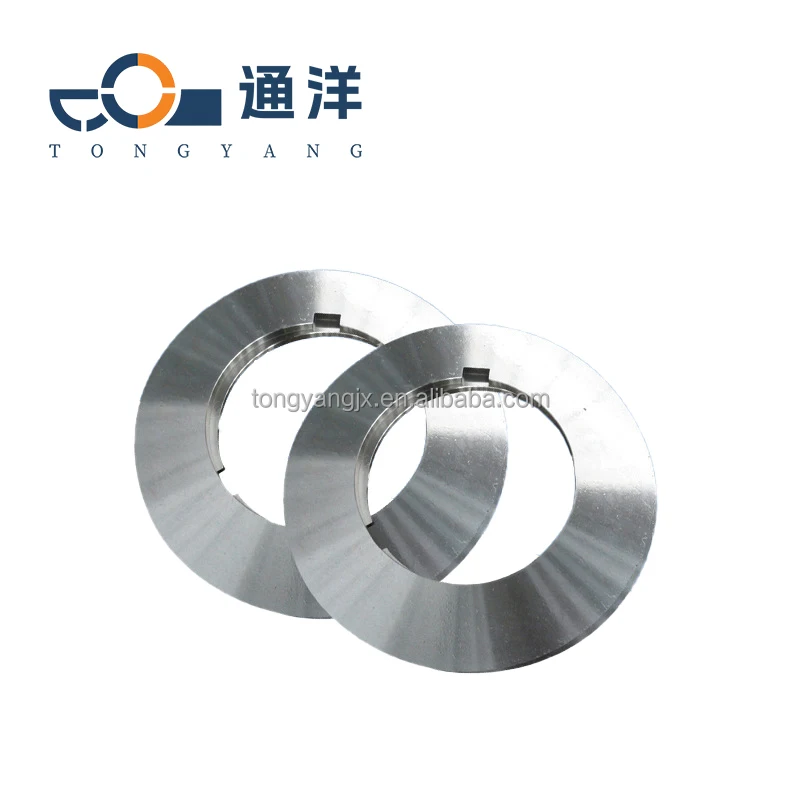

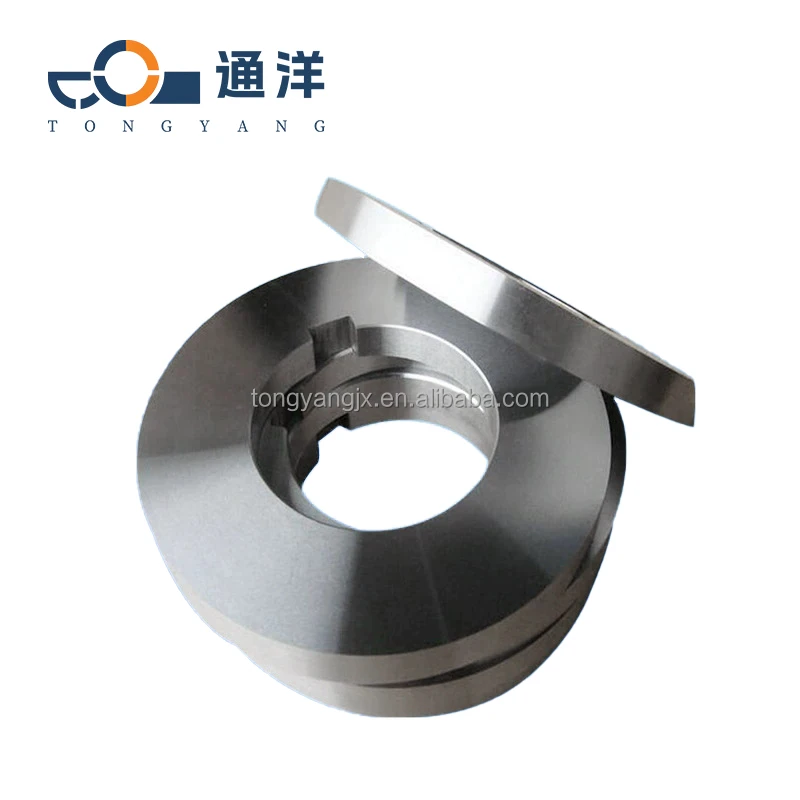

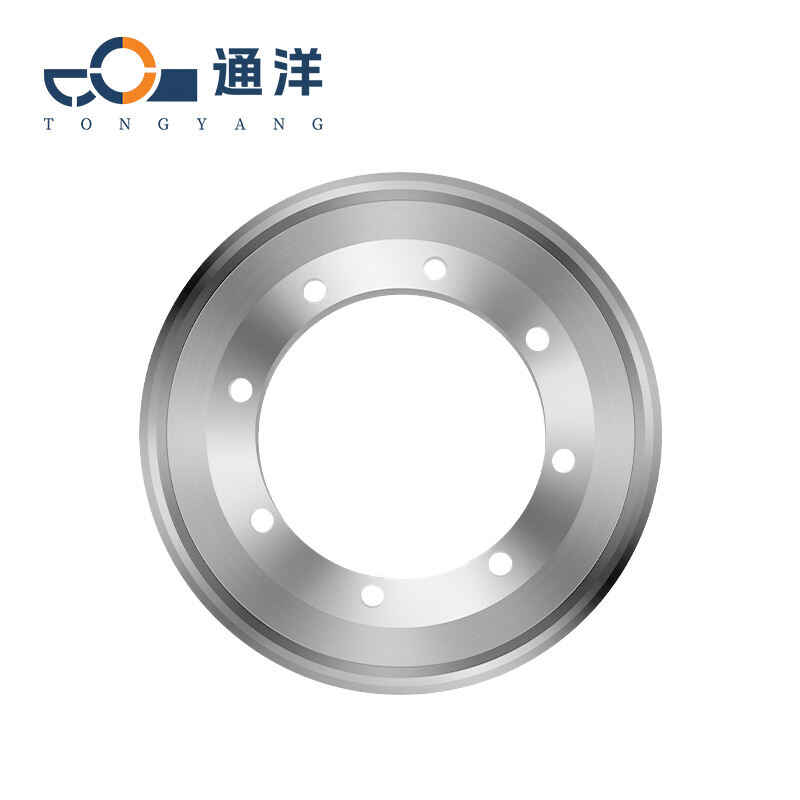

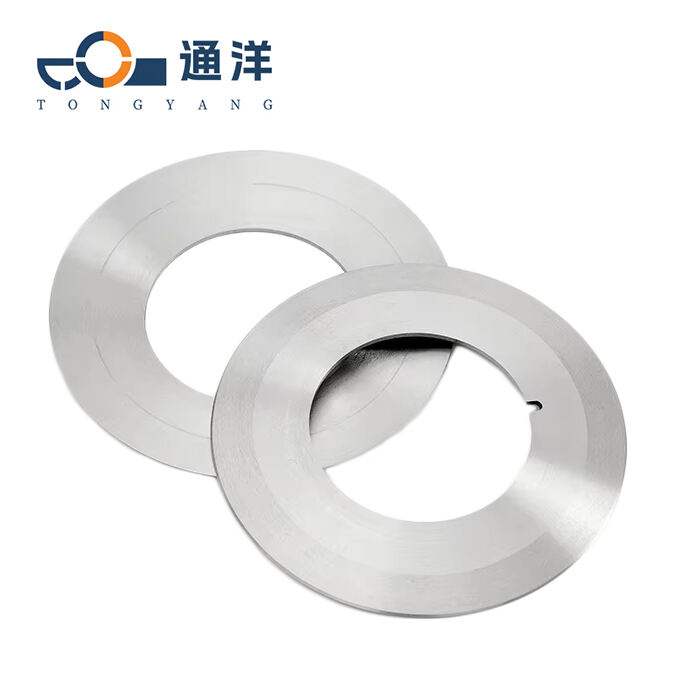

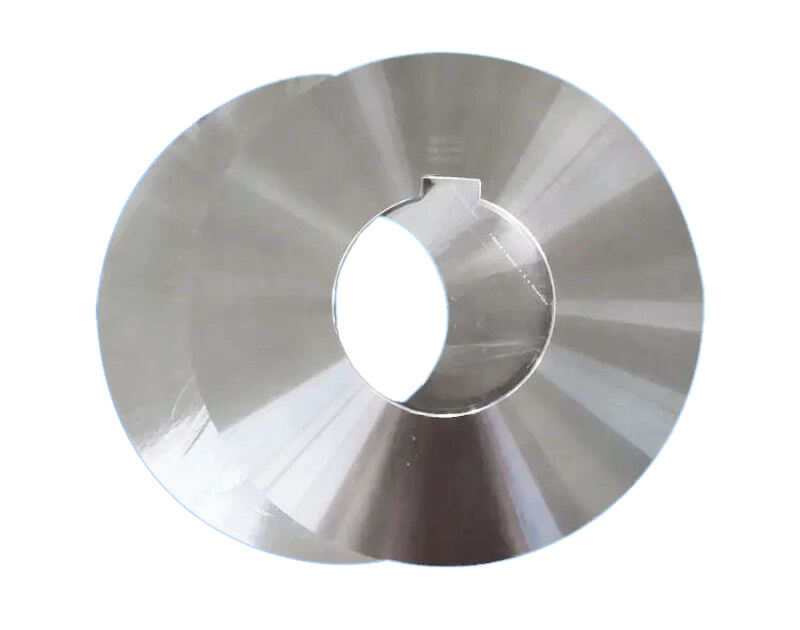

Slab cutting blade

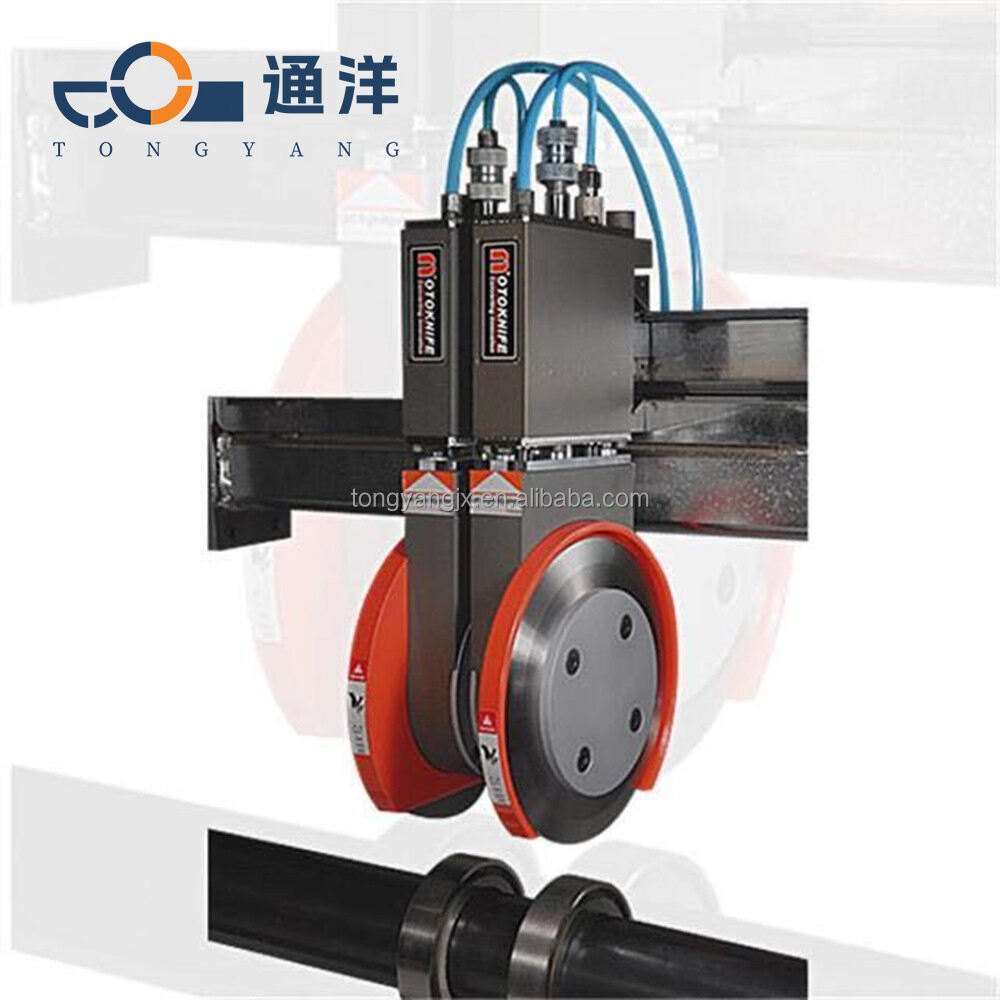

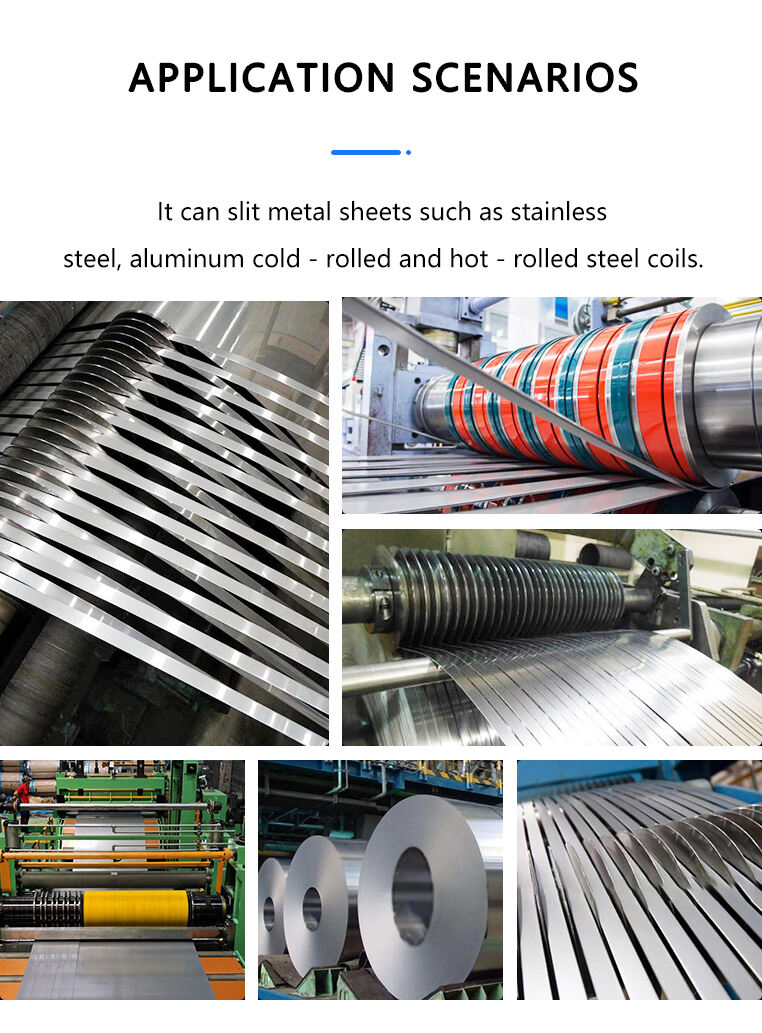

Metal slitting machine blades are primarily used to slit metal sheets into strips, ensuring that the cut edges are flat, burr-free, and free from stretching deformation. The selection of blade materials can be tailored to the thickness of the metal sheets being cut.

- Overview

- Recommended Products

Common materials and applications

High-speed steel

Material characteristics:It has relatively high hardness, strength, and wear resistance, and can maintain good cutting performance under high-speed cutting conditions. It is not prone to chipping when cutting metal sheets.

Application:It can achieve a smooth cutting surface without burrs when cutting metal plates. It is widely used for cutting metals such as copper, aluminum, stainless steel, etc.

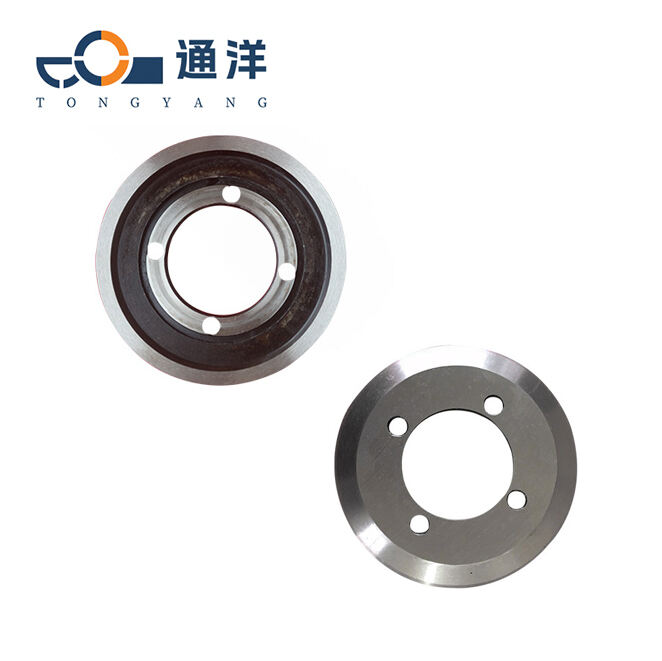

Cemented carbide blade

Material characteristics:Cemented carbide can easily cut metal materials of various hardness levels, such as stainless steel, copper, aluminum, etc. It is not prone to breakage or chipping during the cutting process, which improves the service life and stability of the cutting tool.

Application:The cemented carbide longitudinal shearing machine blades can accurately cut the metal plates to the required dimensions, and are widely used in the processing of metal plates in the automotive manufacturing field. By strictly controlling the precision and quality of the processed materials, they can effectively improve the manufacturing level of key automotive components and provide a solid guarantee for the safety of the whole vehicle.

Alloy steel

Material characteristics:Alloy steel, with elements such as chromium, nickel and molybdenum added, has excellent toughness and impact resistance, and is suitable for high-speed and heavy load cutting. After heat treatment, its hardness reaches HRC55-65. It is wear-resistant has a long service life, features good thermal stability, and can ensure the cutting accuracy. Compared with cemented carbide, it has strong machinability, can be made into blades of various specifications and is applicable to all kinds of longitudinal shearing machines.

Application:Alloy steel blades have excellent adaptability for the longitudinal shearing processing of common metal plates such as carbon steel and low alloy steel. They can not only ensure the cutting accuracy but also efficiently complete the operation. In the processing of metal plates of building materials such as color-coated steel plates and galvanized steel plates, alloy steel longitudinal shearing machine blades also perform outstandingly and can fully meet the strict requirements of building materials for the dimensional accuracy and surface quality of the plates.

Material customization

We also provide customization services for other materials

For each customized product, the material inspection will be carried out by a spectrometer.

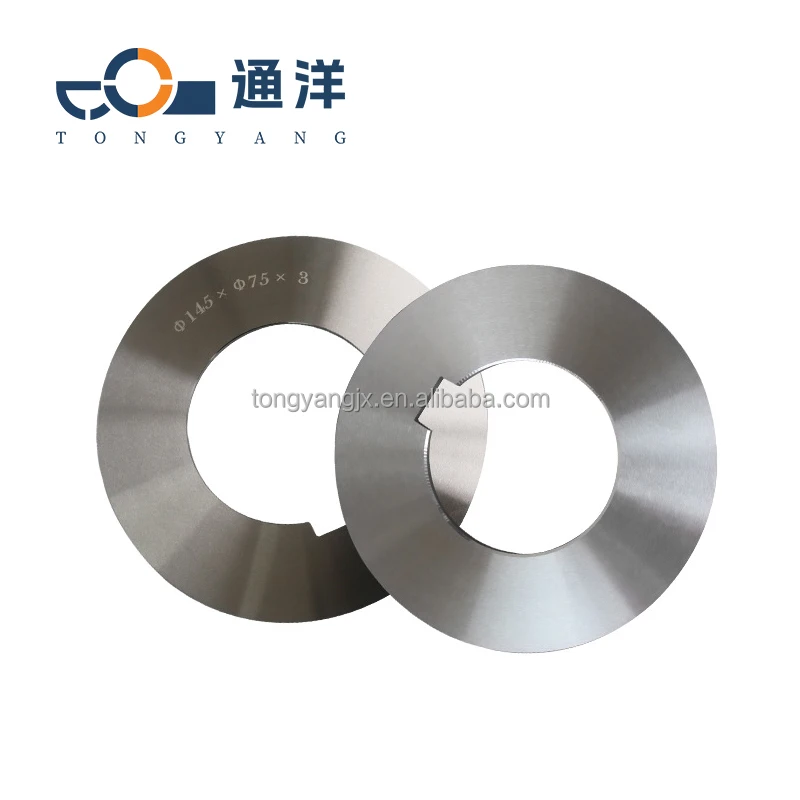

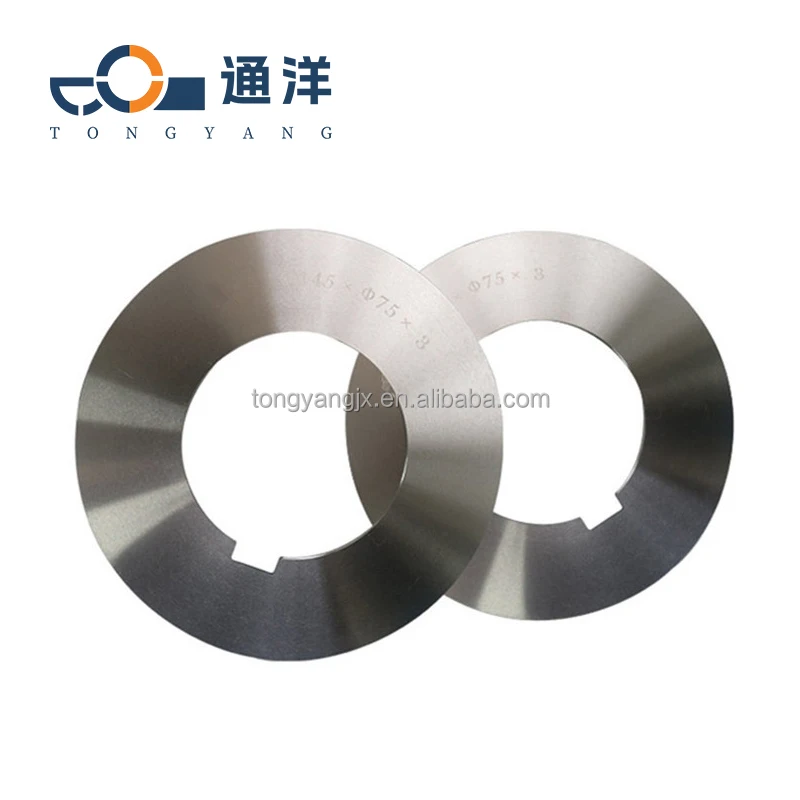

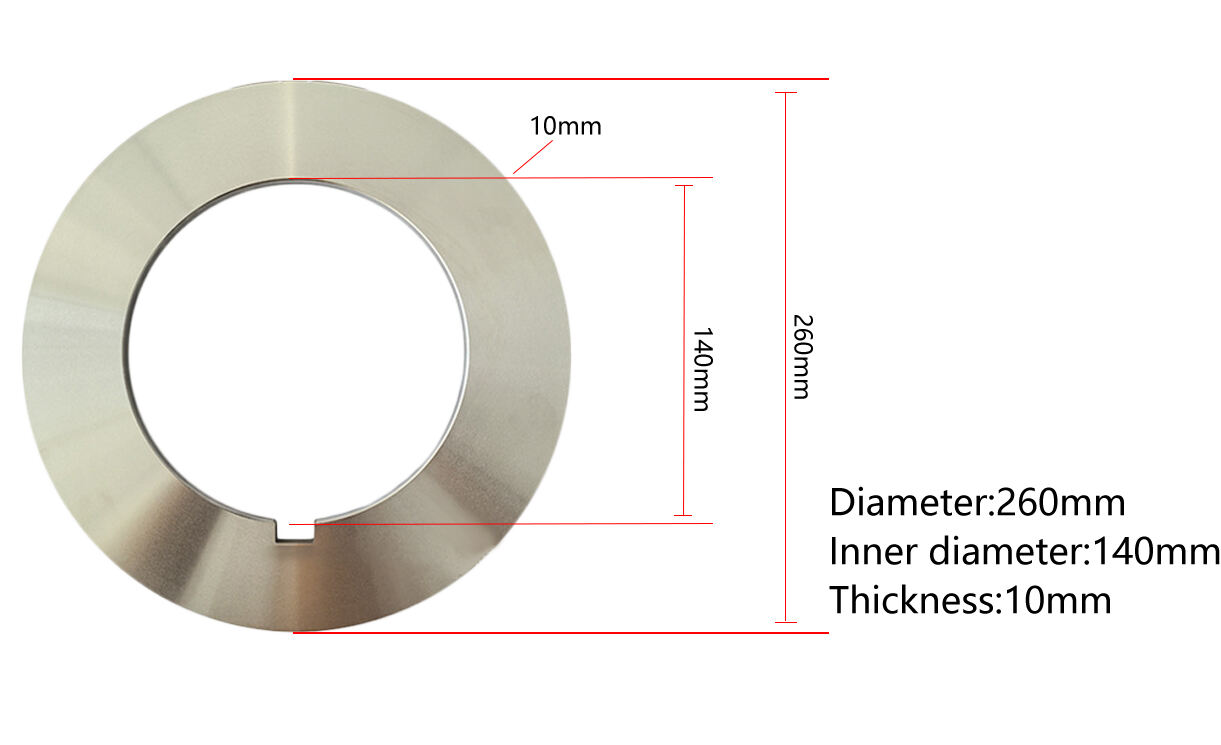

Common specifications

| Diameter | Inner diameter | Thickness | Application |

| 260mm | 140mm | 10mm | Suitable for longitudinal shearing of thin - gauge carbon steel and low - alloy steel sheets in small - scale processing. |

| 280mm | 160mm | 10mm | Can be used for continuous longitudinal shearing operations of common - thickness metal sheets in general machinery manufacturing. |

| 360mm | 200mm | 10mm | Applied to the longitudinal shearing of metal sheets in the production of small - and medium - sized electrical enclosures. |

| 380mm | 200mm | 10mm | Ideal for longitudinal shearing of metal sheets in light industrial product manufacturing, like small - sized metal containers. |

| 400mm | 260mm | 10mm | Used for longitudinal shearing of metal sheets in the production of some precision - required small - sized metal structural parts. |

| 440mm | 280mm | 30mm | Applicable to the longitudinal shearing of medium - thickness metal sheets in the construction of general - sized steel structures. |

| 500mm | 300mm | 40mm | Suited for longitudinal shearing of thicker metal sheets in large - scale equipment manufacturing, such as parts of heavy machinery. |

| 550mm | 380mm | 40mm | Applied to the longitudinal shearing of metal sheets in the manufacturing of large - sized construction machinery components. |

| 650mm | 420mm | 50mm | Used for longitudinal shearing of thick metal sheets in large - scale shipbuilding and bridge construction projects. |

| 800mm | 500mm | 60mm | Ideal for longitudinal shearing of extra - thick metal sheets in large - scale heavy - duty industrial equipment manufacturing. |

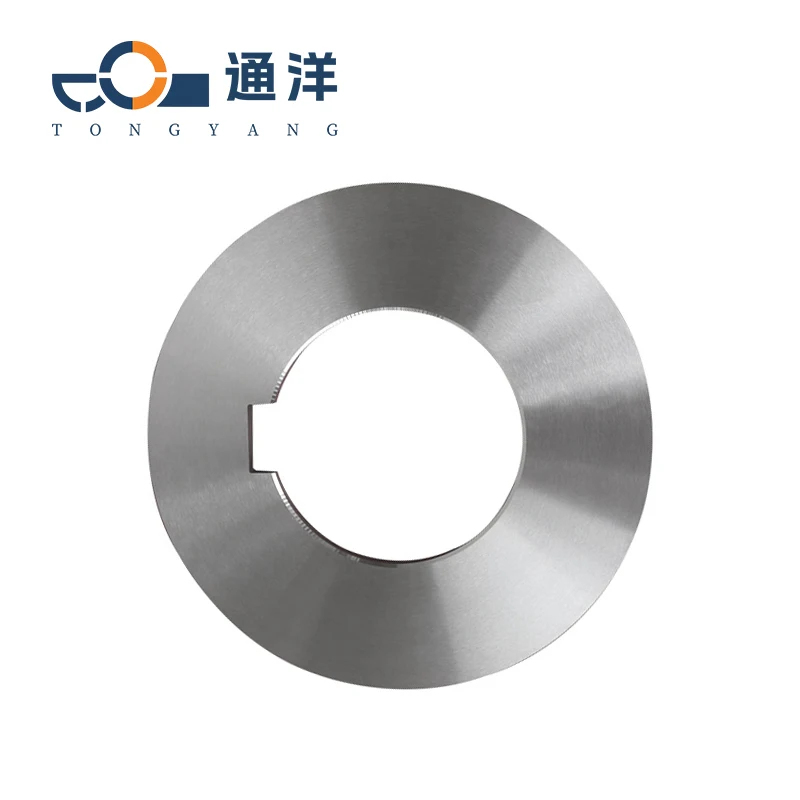

When customizing, it is necessary to provide the drawings or specific parameters of the cutting tool. Please measure the specifications that are suitable for the mechanical blade before customization(Parameters such as diameter, inner diameter, thickness, and punching)

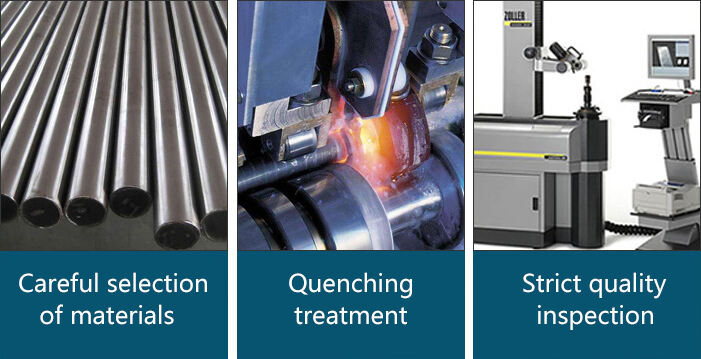

Our advantages

From material selection, production to quality inspection, we strictly follow the Standard Operating

Procedure (SOP). In the material selection process, we have in-depth cooperation with top suppliers in the industry and carefully select high-purity and high-performance raw materials such as high-quality steel and cemented carbide to ensure that every industrial blade has excellent hardness, wear resistance, and red hardness from the source.

During the production process, we use numerically controlled precision machining equipment and cutting edge manufacturing processes, implementing precision requirements throughout every single procedure. Whether it is the edge grinding of the blade, heat treatment strengthening, or the shaping of the overall structure, we strive for perfection.In the quality inspection stage, we adopt a multi-dimensional inspection system, covering dozens of strict indicators such as hardness testing, sharpness inspection, wear resistance simulation, and dimensional accuracy calibration. Through the dual verification of professional instruments and manual rechecking, we prevent any defective products from entering the market.

Each in-stock model will go through a strict on-machine testing process. By simulating real cutting scenarios, a comprehensive inspection will be carried out on key indicators such as the sharpness, cutting precision, and stability of the blade to ensure that each blade can achieve excellent cutting results.