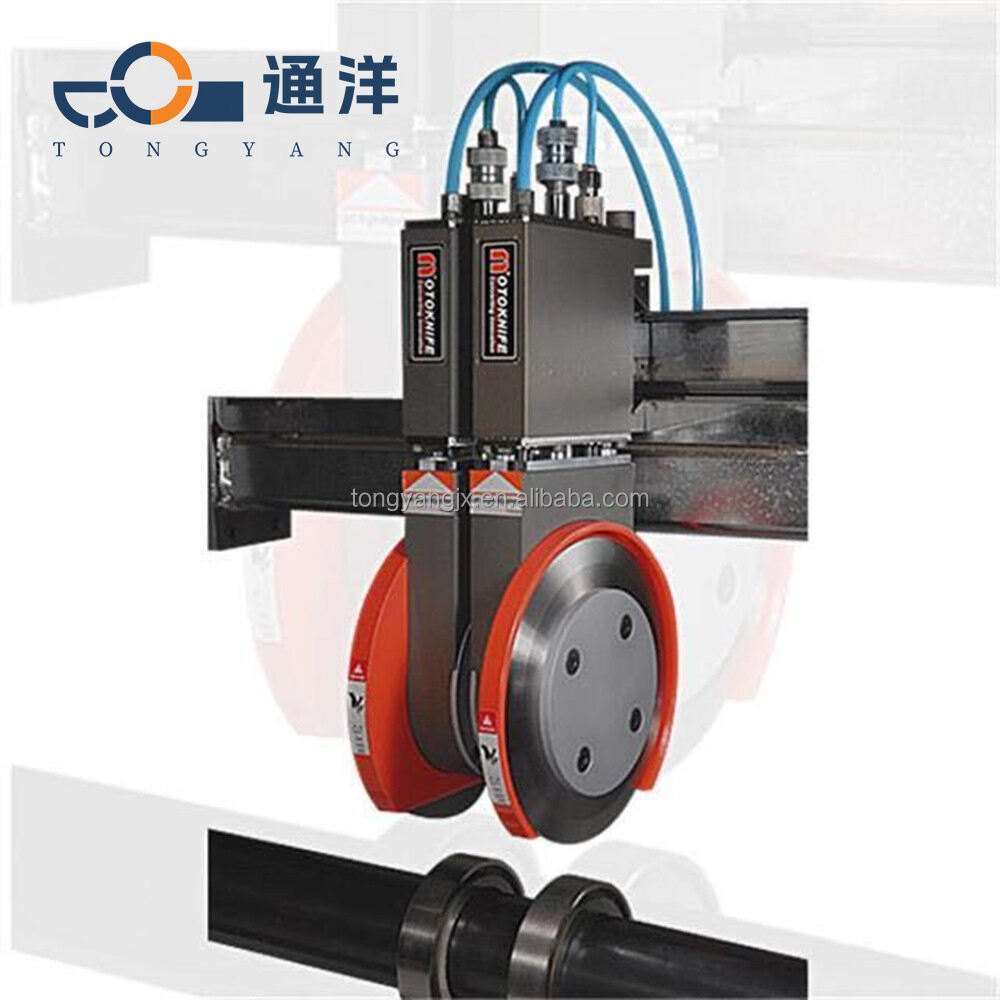

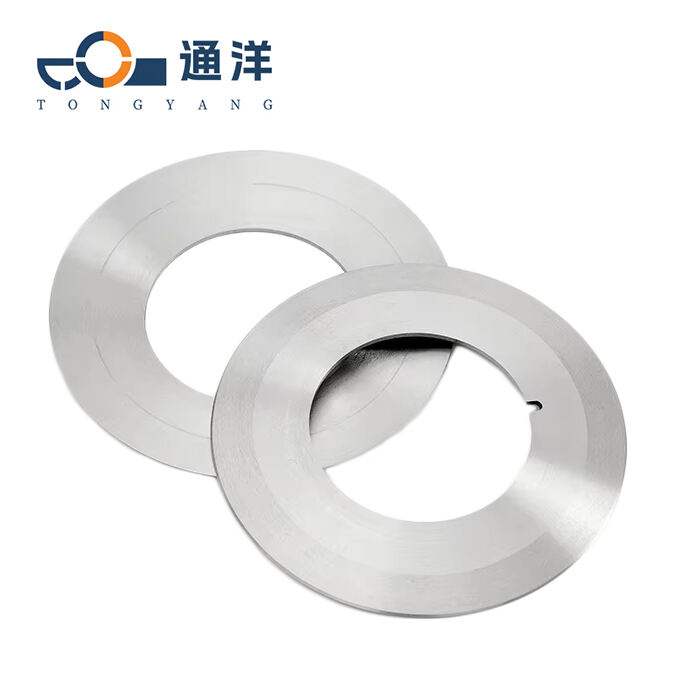

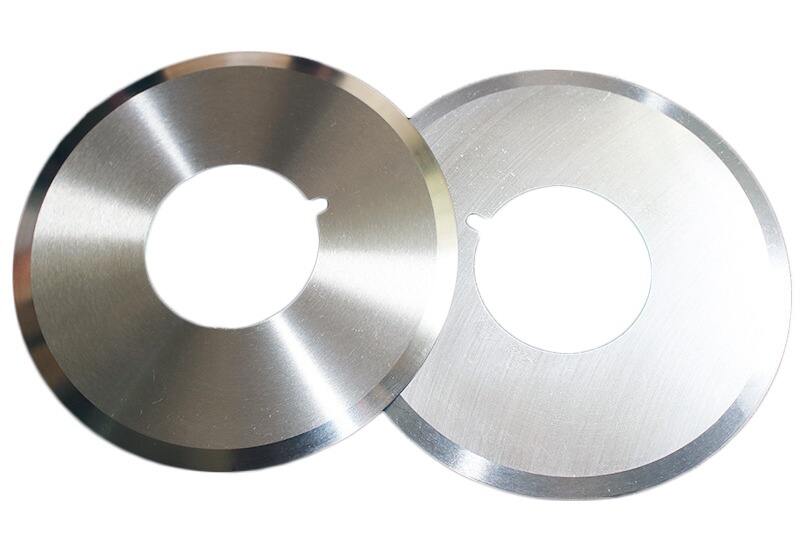

Blades for cloth slitting machines

It is suitable for slitting common fabrics such as ordinary cotton, linen, chemical fibers etc. These fabrics have relatively soft textures and do not have high requirements for the wear resistance and corrosion resistance of the blades. High carbon steel blades, with their cost advantages and basic cutting performance, can meet the daily fabric slitting needs.

- Overview

- Recommended Products

Materials and Their Applications

High carbon steel

Material characteristics:High carbon steel is a kind of material with relatively low price, which can effectively control the production cost. After professional heat treatment, high carbon steel blades can obtain a relatively high hardness, meeting the hardness requirements for general fabric slitting, and ensuring the sharpness and wear resistance of the blades. High carbon steel has excellent cutting and machining properties, and can meet the installation and usage requirements of different fabric slitting machines.

Application:It is suitable for slitting common fabrics such as ordinary cotton, linen, chemical fibers etc. These fabrics have relatively soft textures and do not have high requirements for the wear resistance and corrosion resistance of the blades. High carbon steel blades, with their cost advantages and basic cutting performance, can meet the daily fabric slitting needs.

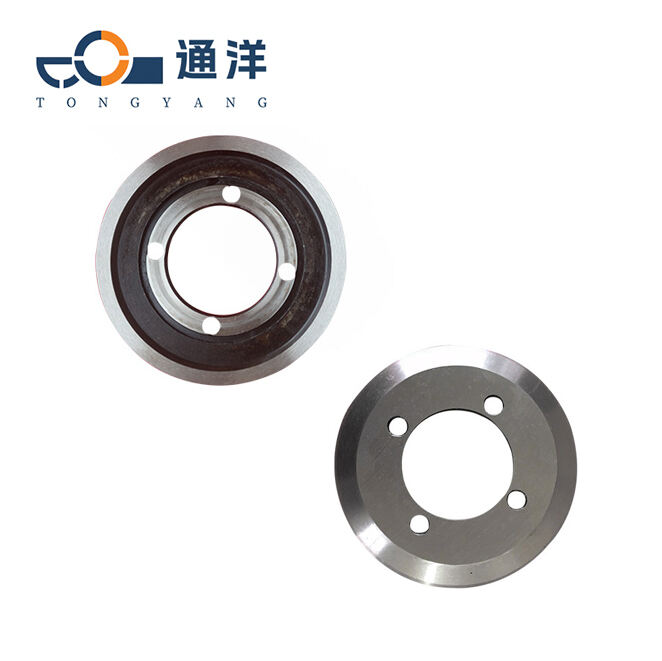

High-speed steel

Material characteristics:After quenching and tempering,high-speed steel blades have excellent wear resistance. They can keep the blade edge sharp during long-time slitting, reducing the replacement frequency. During high-speed or long-time continuous operation, they can maintain hardness and strength at high temperatures, preventing the blade edge from softening and ensuring the slitting quality and efficiency. Compared with high-carbon steel, high-speed steel has better toughness. It can withstand impact and vibration, is less prone to chipping or breaking, and significantly improves the service life and stability of the blade.

Application:It is commonly used for slitting some fabrics with relatively hard textures and high strength,such as denim, canvas, leather, etc. High-speed steel blades can meet the requirements of high-speed and high-efficiency slitting, while ensuring the slitting quality and reducing problems such as burrs on the fabrics and uneven cut edges. For special fabrics that require high-precision slitting, high-speed steel blades can also meet the slitting precision requirements with their excellent performance.

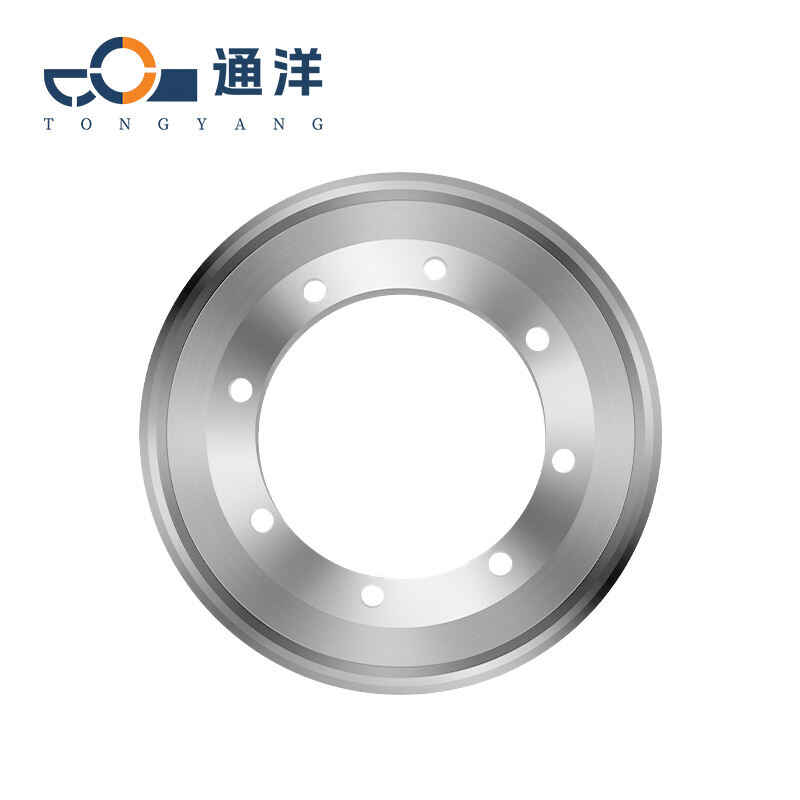

Tungsten steel

Material characteristics:Tungsten steel has good corrosion resistance and is not easily corroded by the chemical substances in the fabric or the external environment. Tungsten steel also has excellent wear resistance. During the slitting process, it can maintain the straightness and perpendicularity of the blade edge, enabling high-precision fabric slitting.

Application:It is mainly used for the slitting of high-end textile fabrics such as silk and cashmere. Tungsten steel blades are suitable for high-speed and high-precision slitting, which can improve production efficiency and product quality. At the same time, in the slitting of special fabrics with high strength and high toughness, such as bulletproof fabrics and fireproof fabrics, tungsten steel blades are also widely used due to their excellent performance.

Material customization

We also provide customization services for other materials

For each piece of custom-made product, the material inspection will be completed by a spectrometer during the factory shipment process.

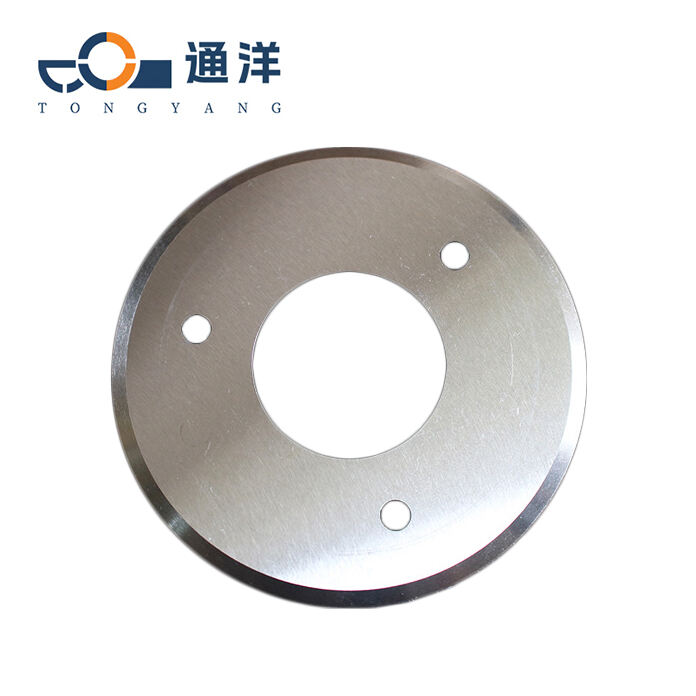

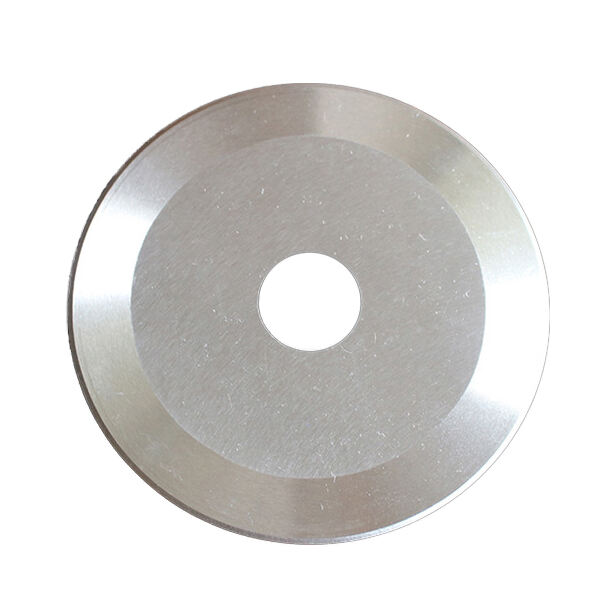

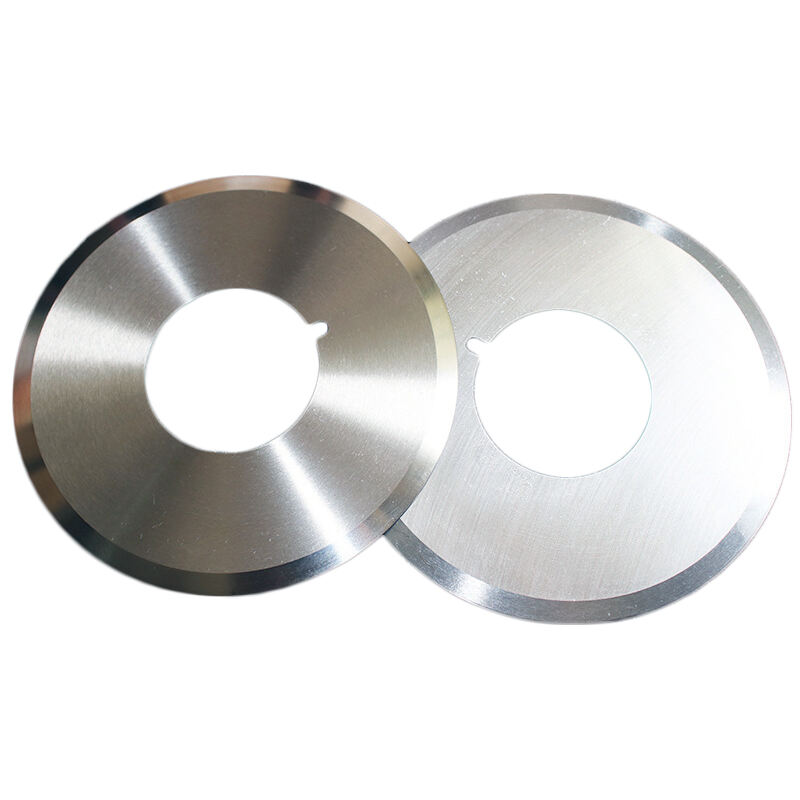

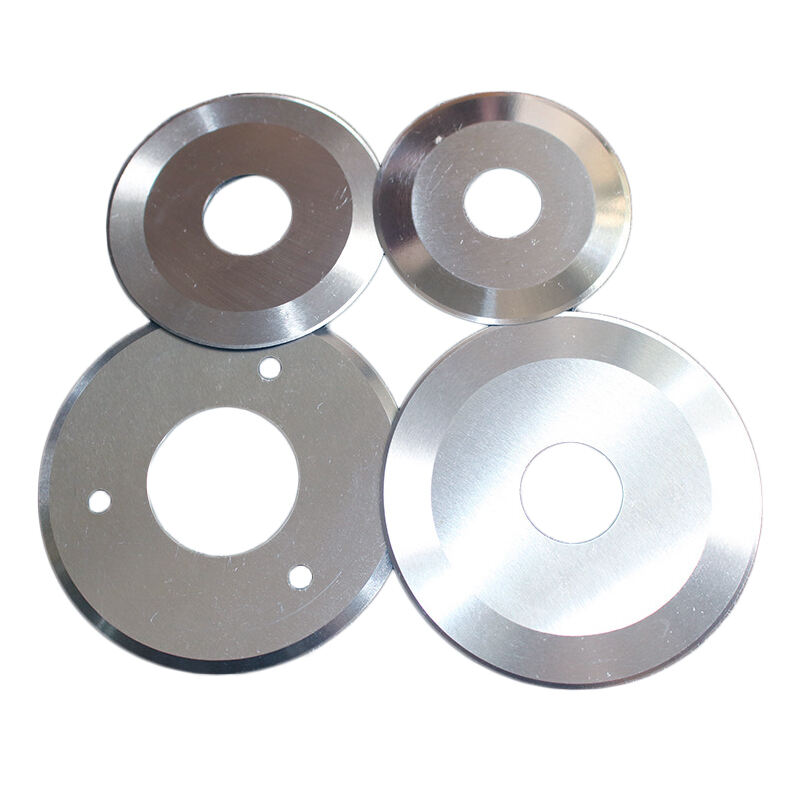

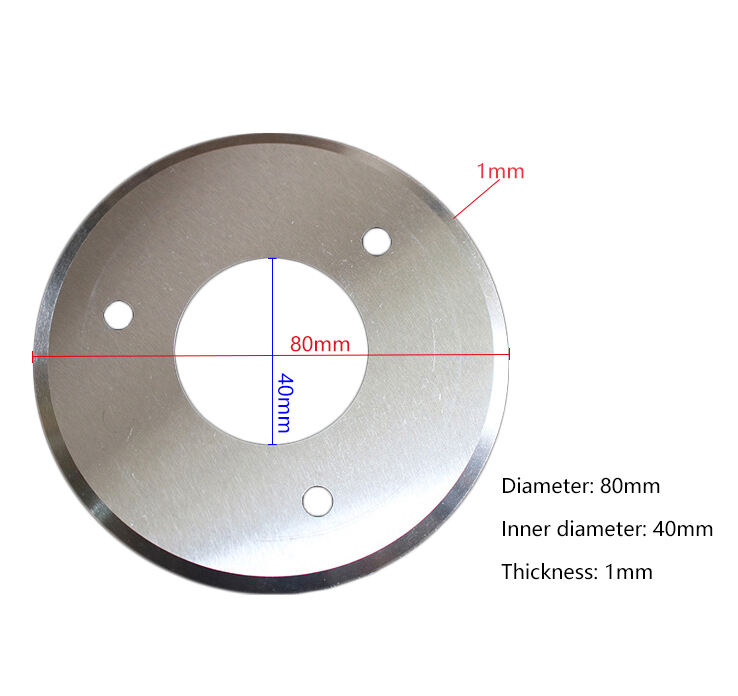

Common specifications

| Diameter | Inner diameter | Thickness | Application |

| 80mm | 40mm | 1mm | This specification is often used for the slitting of natural leather. With a relatively small diameter, it enables high-precision slitting, and the cutting surface is smooth, making it less likely to damage the leather. |

| 90mm | 25.4mm | 1.5mm | When cutting fabrics, it can handle curves and details, and is suitable for the slitting of fabrics with high precision requirements. It can reduce the extrusion of the fabric during high-speed cutting, and decrease the possibility of the fabric wrinkling or deforming. |

| 100mm | 25.4mm | 2mm | The larger diameter and thicker blade body give it more advantages when cutting thick leather or multiple layers of leather stacked together, ensuring the cutting precision and quality, and making the cutting surface free of burrs or tearing phenomena. |

When customizing, it is necessary to provide the drawings or specific parameters of the cutting tool (diameter, inner diameter, thickness, material).

Our advantages

Customize

Precise Specification Adherence: Our experienced engineers and technicians are proficient in handling various specification requirements. Once your requirements are clear, we ensure that every parameter, from the dimensions of components to the performance indicators of the entire machine,is strictly adhered to. This precision guarantees that the final customized product not only meets but often exceeds your expectations.

Efficient Production Execution: Equipped with advanced manufacturing equipment and streamlined production processes, we can promptly transform the approved specifications into high - quality products.The optimized production workflow minimizes delays, ensuring that you receive your customized machinery within the promised time frame.

Comprehensive After - sales Support: Our service commitment extends beyond delivery. Our after sales team is always ready to assist you. Whether it's maintenance guidance, spare parts supply, or troubleshooting, we provide prompt and effective support to ensure the long - term smooth operation of your customized equipment.

Reliable Logistics Assurance: We ensure that your customized products are carefully packaged and safely transported to the designated location. Timely tracking and communication during the logistics process keep you informed of every step of the progress.

Quality inspection

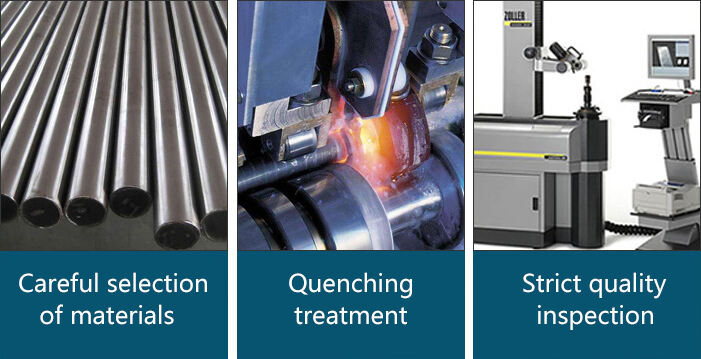

From material selection, production to quality inspection, we strictly follow the Standard Operating Procedure (SOP). In the material selection process, we have in-depth cooperation with top suppliers in the industry and carefully select high-purity and high-performance raw materials such as high-quality steel and cemented carbide to ensure that every industrial blade has excellent hardness, wear resistance, and red hardness from the source. During the production process, we use numerically controlled precision machining equipment and cutting edge manufacturing processes, implementing precision requirements throughout every single procedure. Whether it is the edge grinding of the blade, heat treatment strengthening, or the shaping of the overall structure, we strive for perfection. In the quality inspection stage, we adopt a multi-dimensional inspection system, covering dozens of strict indicators such as hardness testing, sharpness inspection, wear resistance simulation, and dimensional accuracy calibration. Through the dual verification of professional instruments and manual rechecking, we prevent any defective products from entering the market.

We always adhere to the concept of quality first and, with standardized and regulated processes, continuouslyprovide customers with industrial blades that feature high precision, long service life, and stable performance, safeguarding our customers' efficient production.