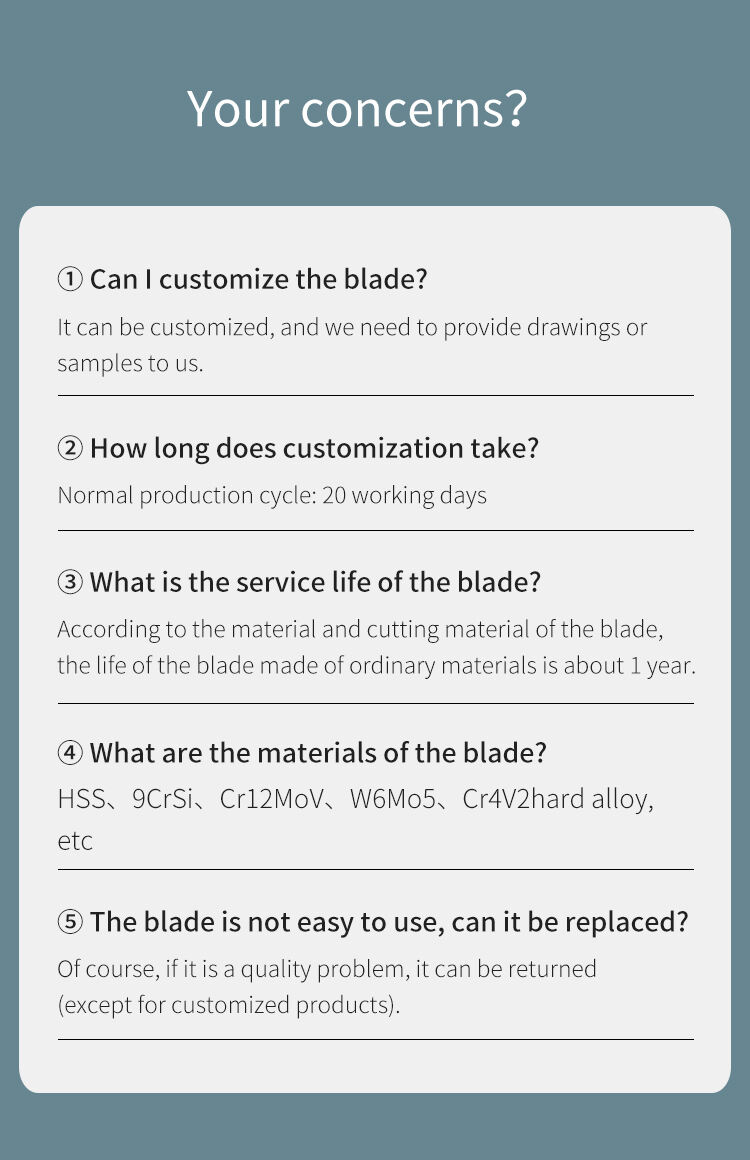

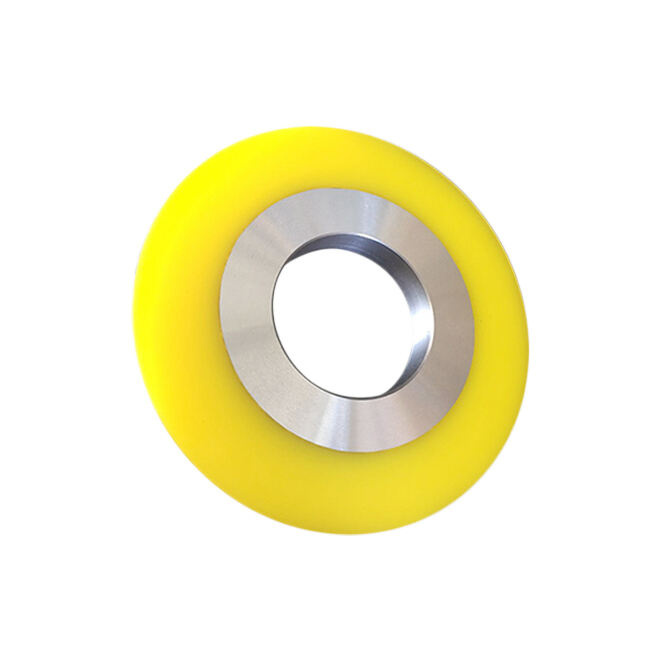

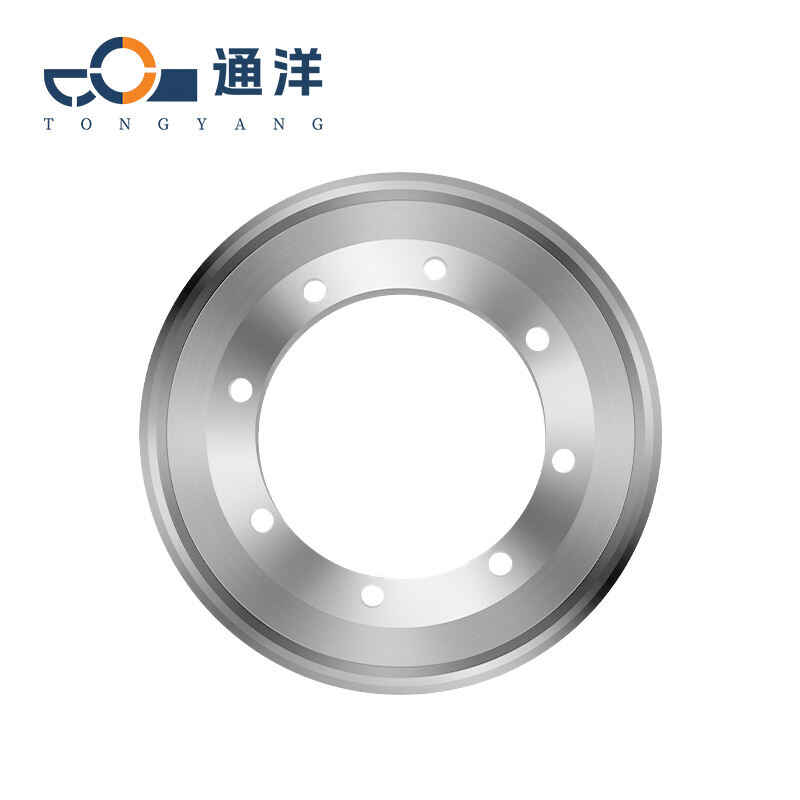

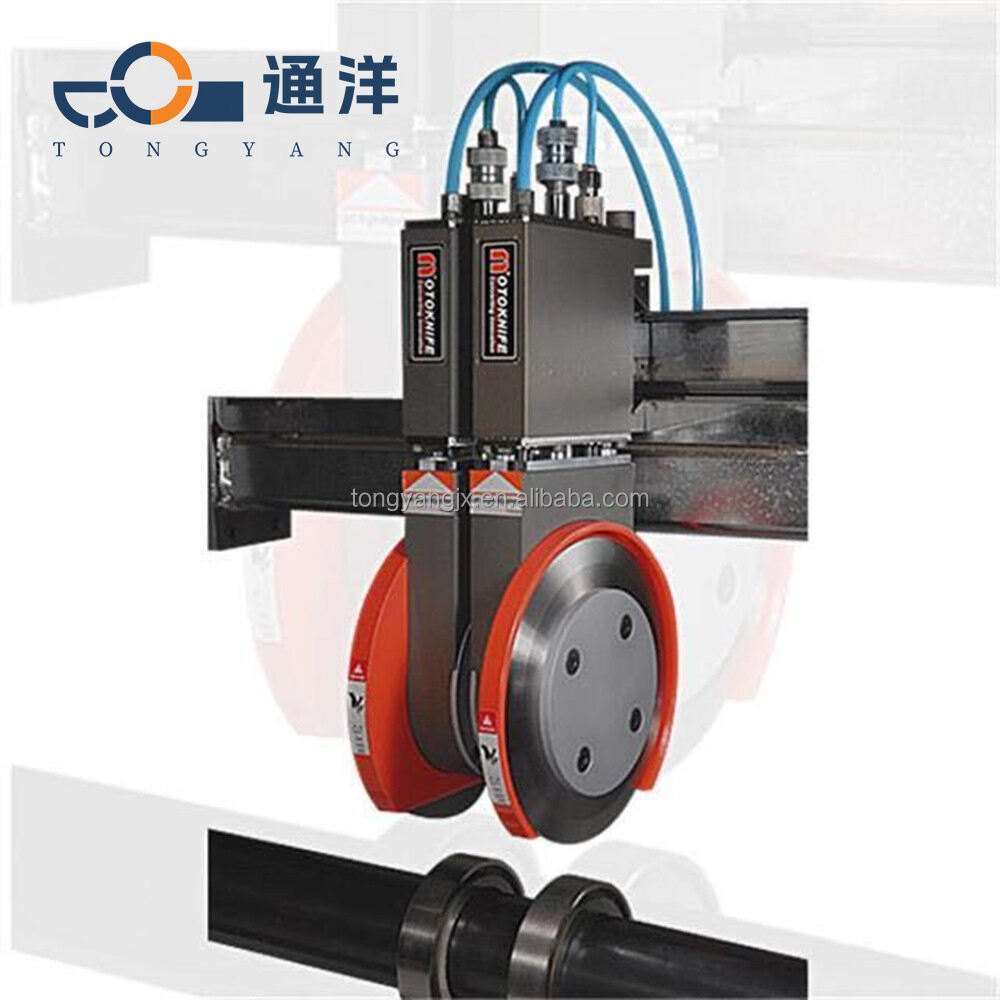

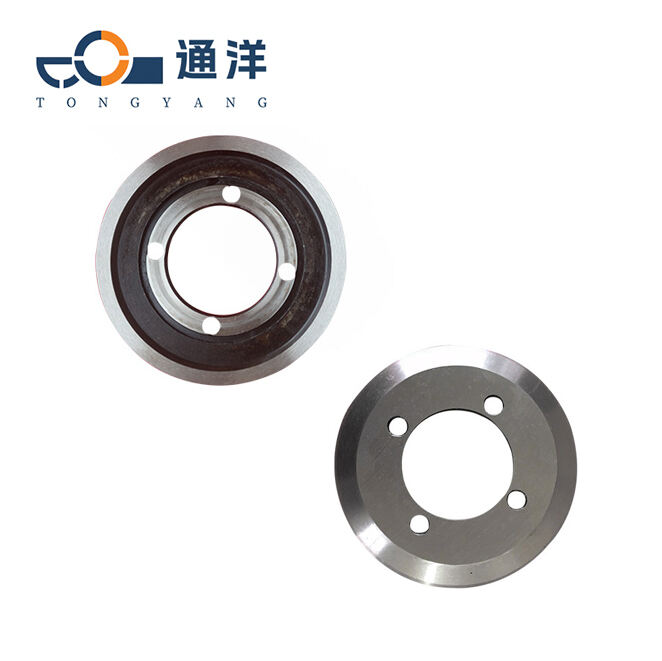

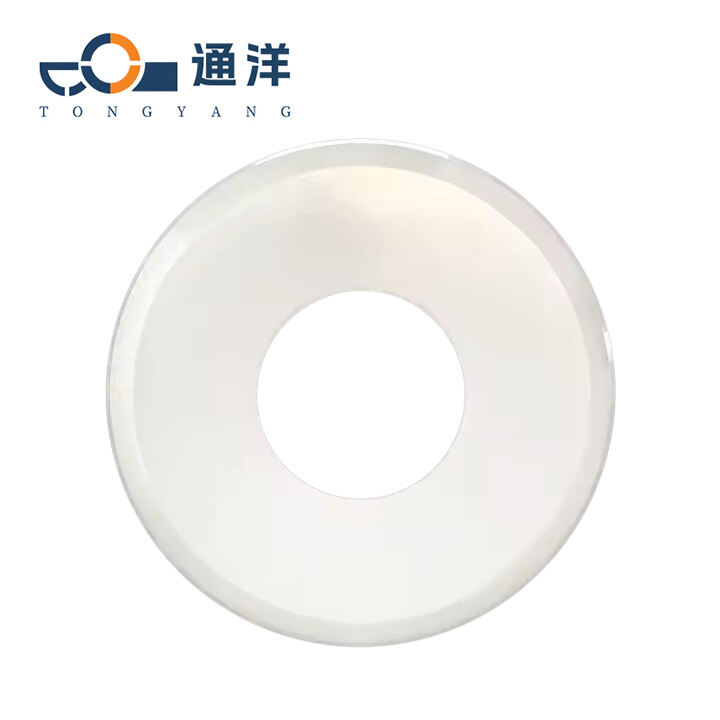

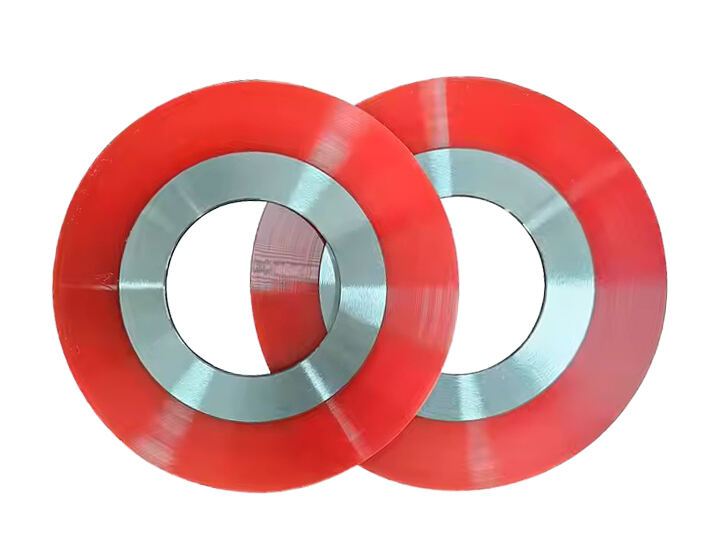

Rubber spacer for longitudinal shearing machine

Rubber washers feature high precision, wear resistance and heat resistance. The materials of rubber rings mainly include polyurethane rubber rings and nitrile rubber rings. Polyurethane rubber rings are mostly used in most cases. The metal rings are generally made of steel, Gcr15 and 9CrSi, with the precision consistent with that of rolling shear discs.

- Overview

- Recommended Products

Common materials and applications

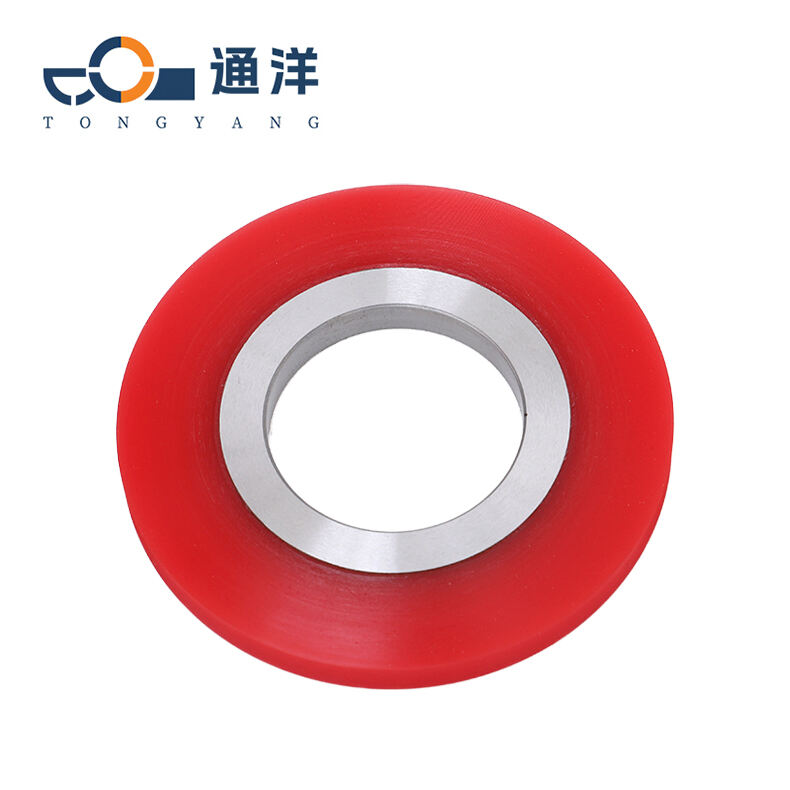

Polyurethane

Material characteristics:It has extremely high strength, wear resistance, tear resistance and good elasticity. Its wear resistance is several times that of natural rubber. At the same time, it also has good oil resistance, chemical corrosion resistance and anti-aging properties and can maintain its performance under significant temperature changes.

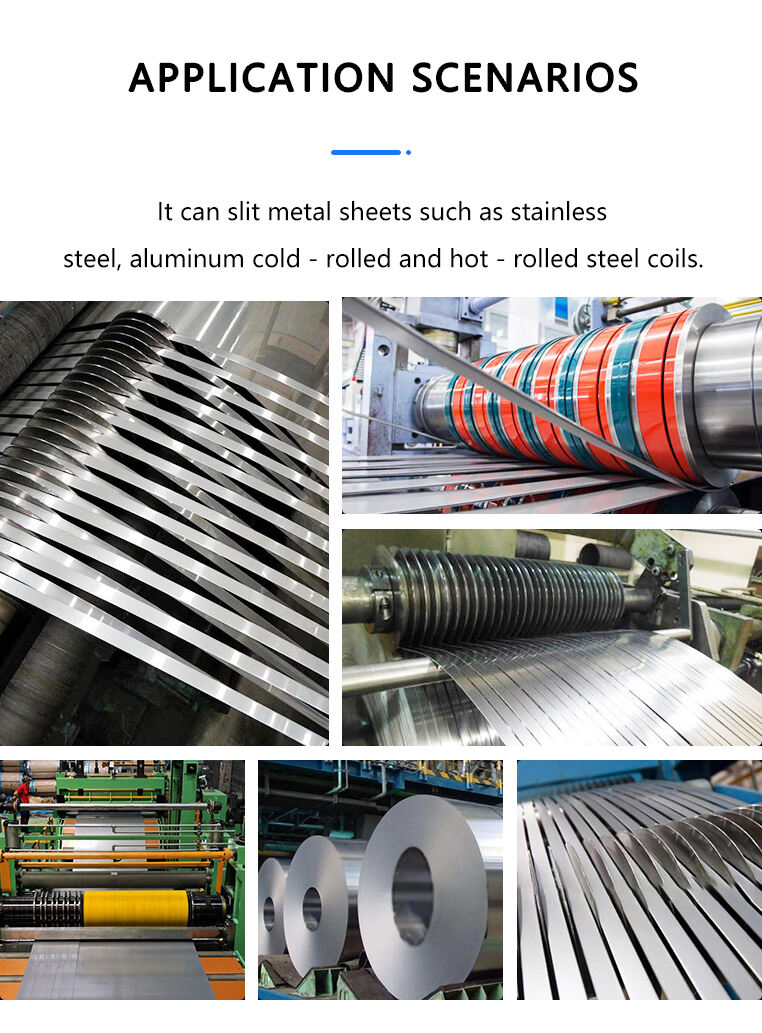

Application:It is suitable for longitudinal shearing machines with high precision requirements and fast shearing speed. It is commonly used for processing metal materials with high hardness such as stainless steel and high-strength alloy steel.

Nitrile rubber

Material characteristics:Excellent oil resistance, with good resistance to mineral oils, animal and vegetable oils, etc.; also has good wear resistance, anti-aging properties, and a certain degree of elasticity, with relatively low cost.

Application:It is widely applied in some situations with high requirements for oil resistance and is used for processing metal sheets with an oil-coated surface. Nitrile rubber can effectively prevent the erosion of oil on metals and extend the service life.

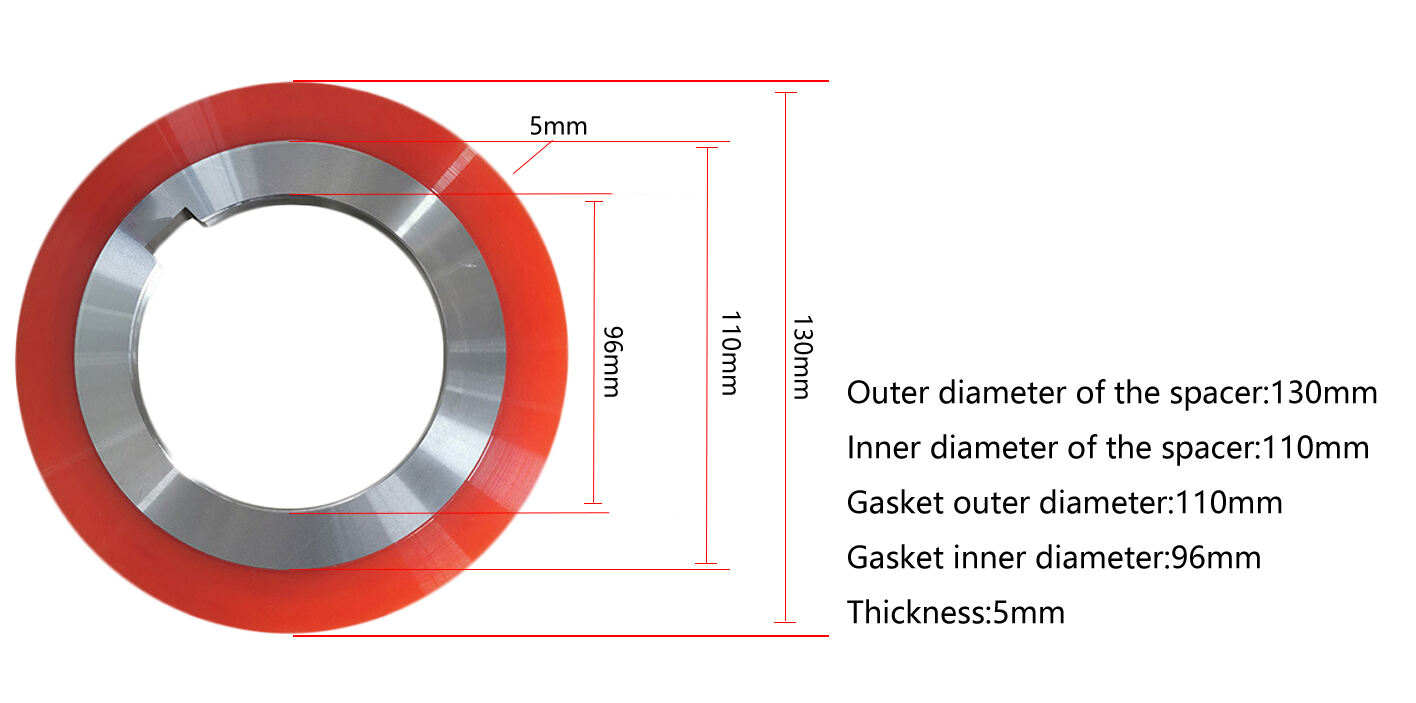

Common specifications

| Outer diameter of spacer | Inner diameter of thr spacer | Gasket outer diameter | Gasket inner diameter | Thickness |

| 130mm | 110mm | 110mm | 96mm | 5mm |

| 130mm | 110mm | 110mm | 96mm | 10mm |

| 130mm | 110mm | 110mm | 96mm | 18mm |

| 170mm | 150mm | 150mm | 130mm | 50mm |

When customizing, it is necessary to provide the drawings or specific parameters of the cutting tool Please measure the specifications that are suitable for the mechanical blade before customization(Parameters such as diameter, inner diameter, thickness, and punching)

Our advantages

The longitudinal shearing machine blades we produce are compatible with various types of metal slitting machines on the market. They have passed strict in - machine tests to ensure stable and efficient operation.Smooth cutting can be achieved when slitting materials such as copper, aluminum stainless steel, and low carbon steel, providing a reliable guarantee for your production and processing.

From material selection, production to quality inspection, we strictly follow the Standard Operating Procedure (SOP) In the material selection process, we have in-depth cooperation with top suppliers in the industry and carefully select high-purity and high-performance raw materials such as high quality steel and cemented carbide to ensure that every industrial blade has excellent hardness, wear resistance, and red hardness from the source.During the production process, we use numerically controlled precision machining equipment and cutting edge manufacturing processes, implementing precision requirements throughout every single procedure. Whether it is the edge grinding of the blade, heat treatment strengthening, or the shaping of the overall structure, we strive for perfection.In the quality inspection stage, we adopt a multi-dimensional inspection system, covering dozens of strict indicators such as hardness testing, sharpness inspection, wear resistance simulation, and dimensional accuracy calibration.Through the dual verification of professional instruments and manual rechecking, we prevent any defective products from entering the market.