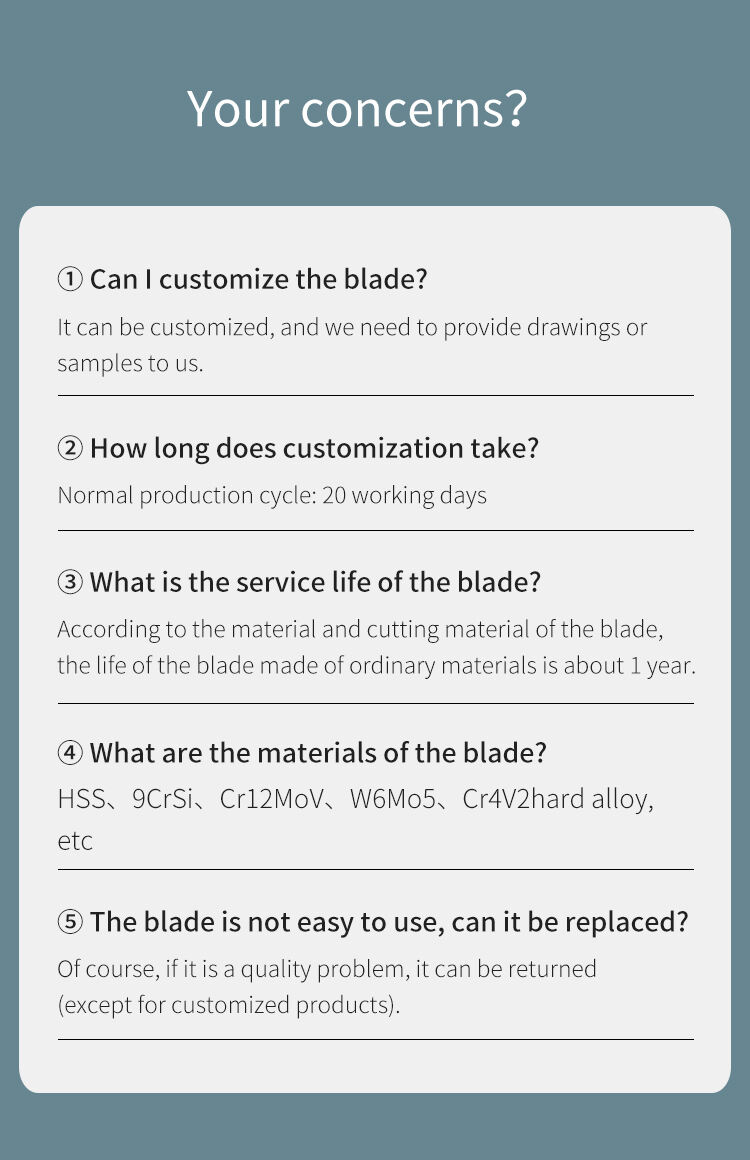

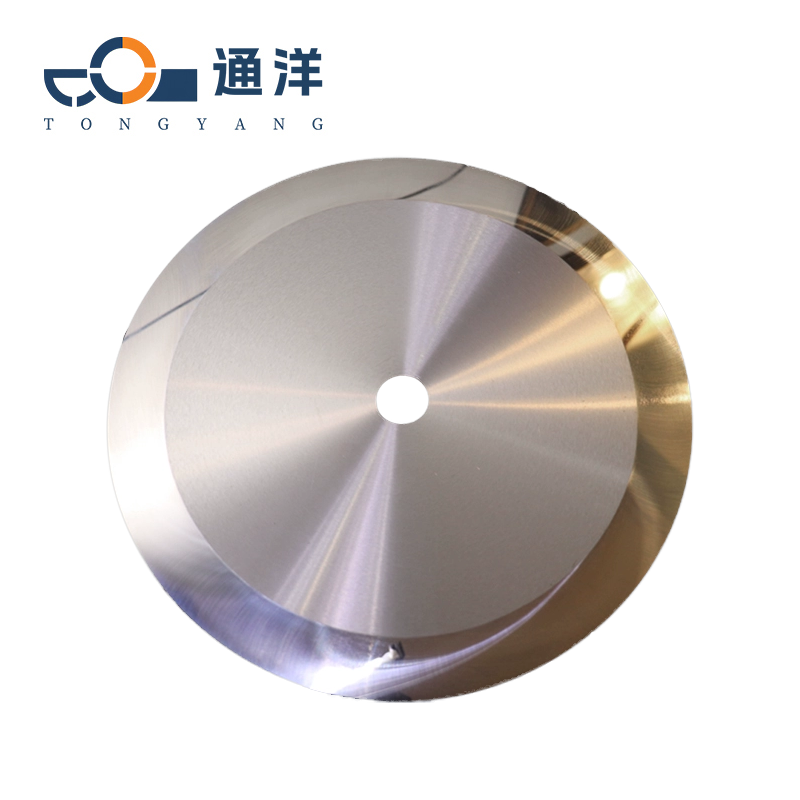

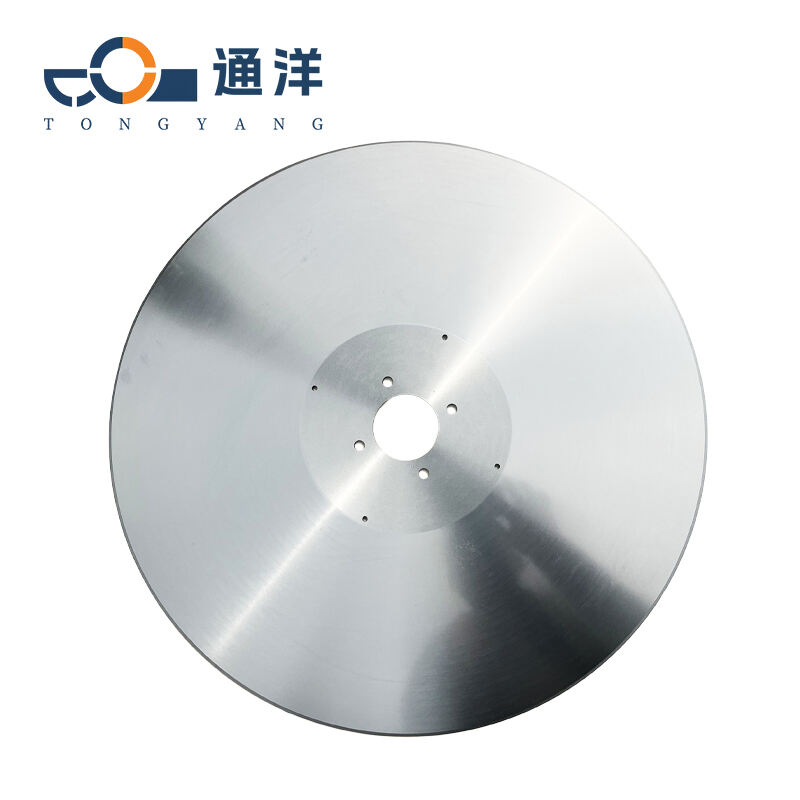

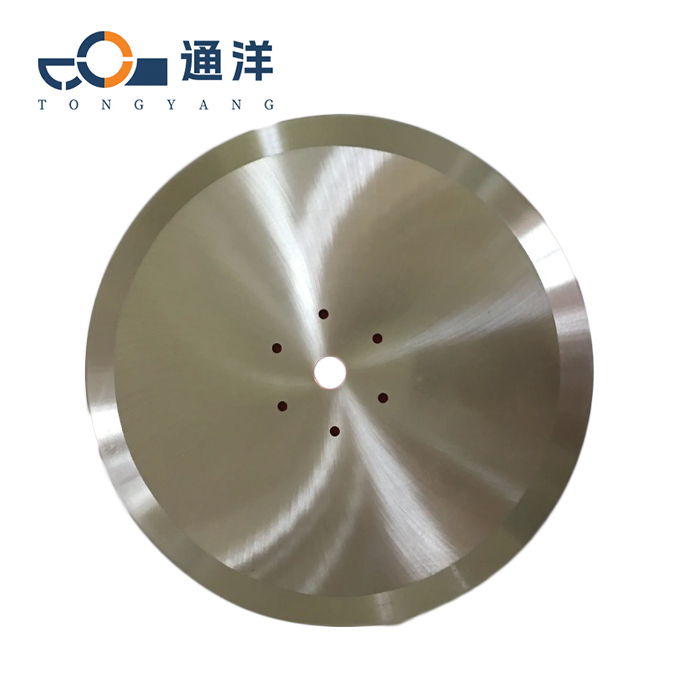

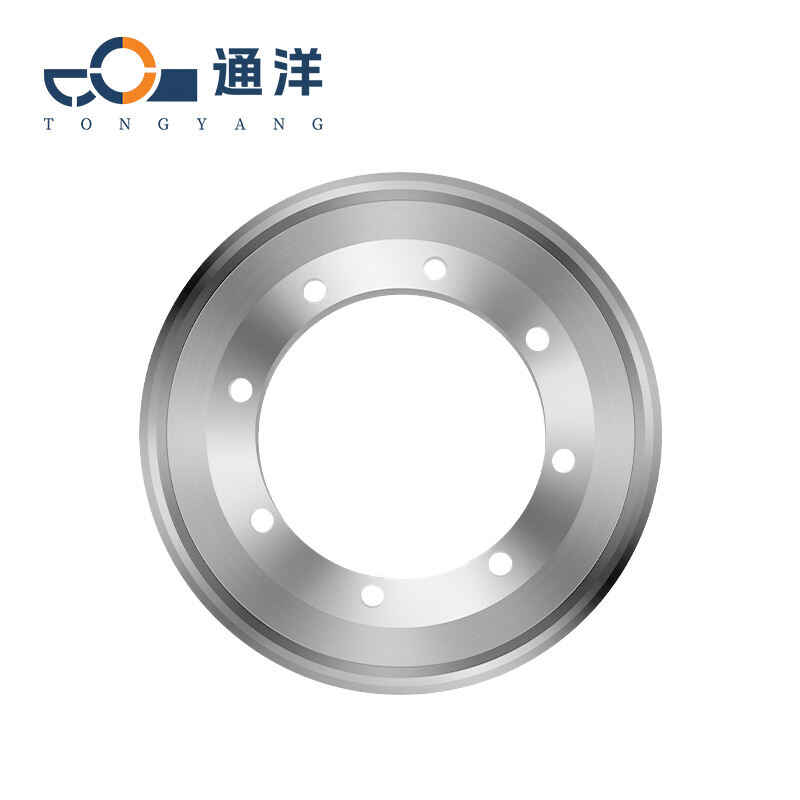

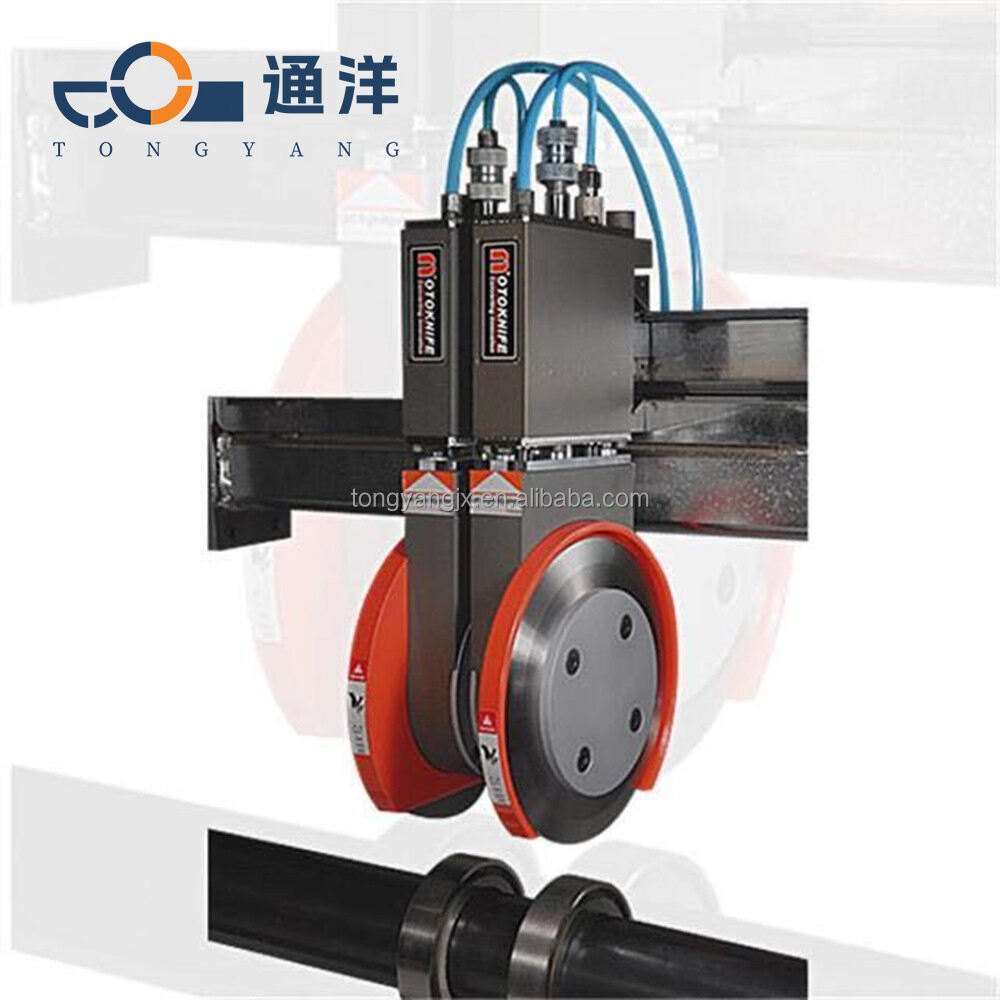

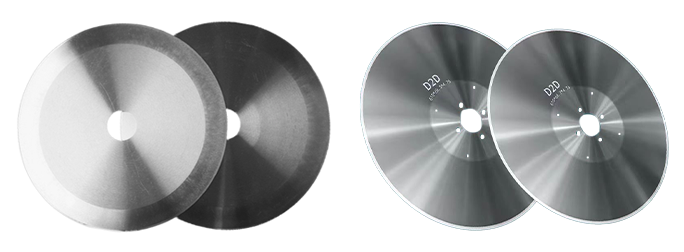

Paper roll slitting knife

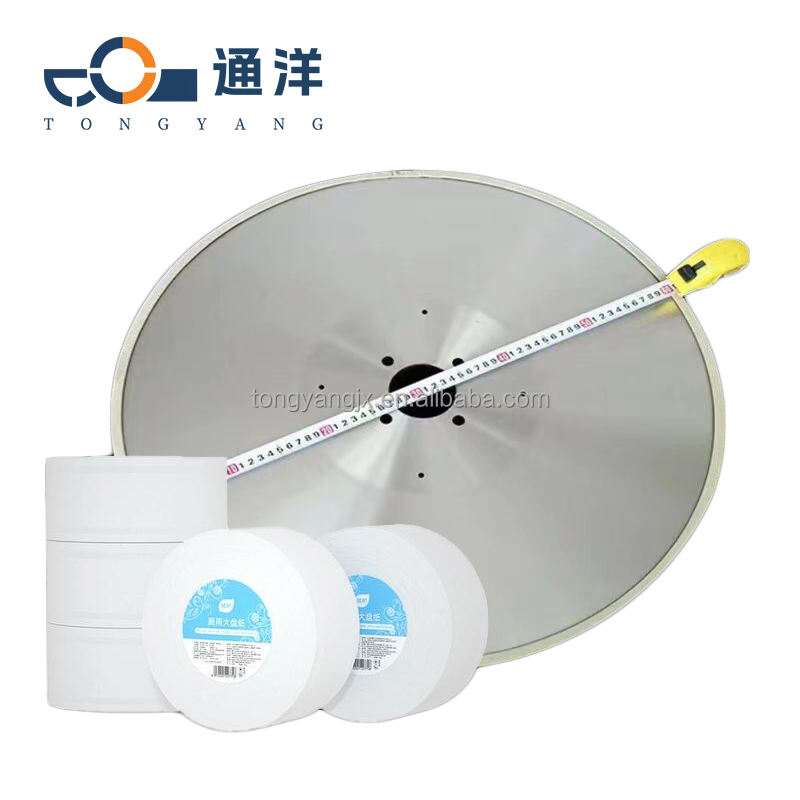

Roll paper cutting blades are professional tools used to slit large rolls of paper (such as mother reels of base paper) into small rolls of specific width or length (such as toilet paper, printing paper, packaging paper, etc.), which are widely applied in the paper making and paper product processing industries. Their core function is to ensure smooth edges, no burrs, and no tears through precise cutting, while meeting the efficiency and tool life requirements of high-speed production lines.

- Overview

- Recommended Products

Common Materials and Applications

High-speed steel

Material characteristics:It has relatively high hardness, good toughness and wear resistance, excellent red hardness, can maintain cutting performance at a certain high temperature, and can withstand a certain impact loadi

Application:It is suitable for the slitting of various paper rolls, including the slitting of daily-use papers such as ordinary toilet paper and napkins. It is widely used in some small-sized paper roll processing enterprises. These enterprises have certain requirements for the comprehensive performance of the slitting knives, and he high-speed steel slitting knives can meet their needs quite well.

SKD-11

Material characteristics:It belongs to the high-carbon and high-chromium cold work die steel. It has extremely high hardness, strength and wear resistance, and shows little deformation after quenching. It is not easy to deform during the cutting process.

Application:It is often used for slitting paper rolls with hard texture and large thickness, such as thick paper rolls for industrial use, special paper rolls, etc. It is widely applied in some professional paper product processing enterprises that have high requirements for slitting accuracy and tool life. For example, in enterprises that produce high-precision packaging paper rolls, the SKD-11 slitting knife can maintain a stable slitting effect during long-term use.

9CrSi

Material characteristics:It has relatively high hardness and good wear resistance, can maintain excellent sharpness of the cutting edge, has a certain degree of toughness, and its price is moderate.

Application:It is suitable for the slitting of ordinary paper rolls, such as general cultural paper rolls and office paper rolls. It can meet the daily slitting requirements of paper rolls and, with its cost-performance advantage, help customers reduce production costs.

SKH-51

Material characteristics:SKH-51 is a high-performance high-speed steel, which has high hardness, high wear resistance, high red hardness and good cutting performance. It can still maintain excellent edge sharpness and strength under high-temperature and high-speed cutting conditions.

Application:It is mainly applied to high-speed and high-precision paper roll slitting production lines, such as the automated paper roll slitting processes in large-scale paper mills, as well as the slitting of special paper rolls with extremely high requirements for slitting quality, such as electronic-grade dust-free paper rolls and high-grade artistic paper rolls. It can achieve precise slitting on high-speed operating equipment, ensuring the quality and precision of the paper rolls.

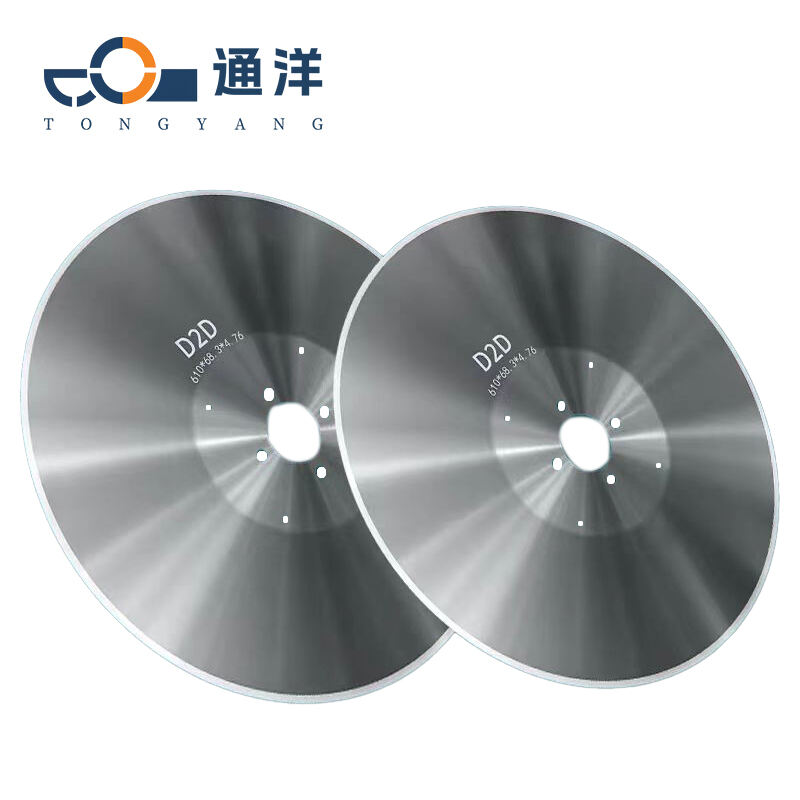

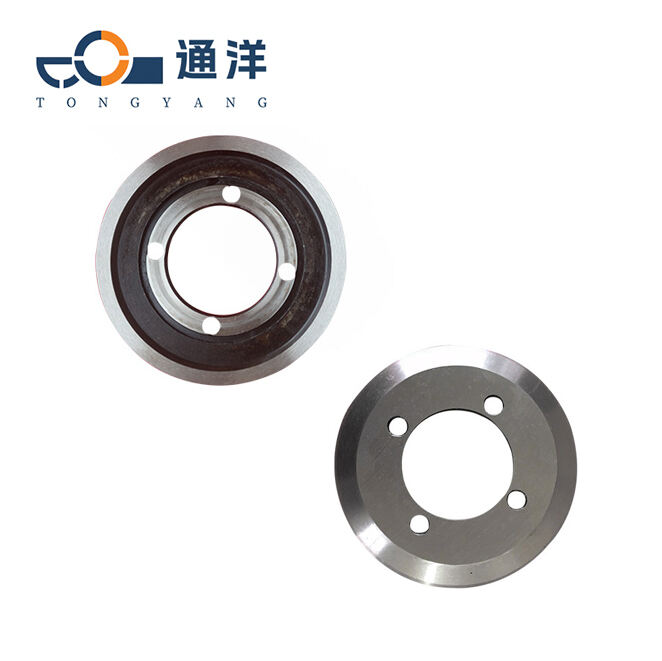

Common specifications

| Diameter | Inner diameter | Thickness | cutting edge |

| 610mm | 68.3mm | 4.76 | Single edge / Double edge |

| 200mm | 25.4mm | 2.5/3mm | --- |

| 250mm | 25.4mm | 2.3/3mm | --- |

| 300mm | 25.4mm | 2.5/3mm | --- |

| 350mm | 32mm | 3mm | Single edge / Double edge |

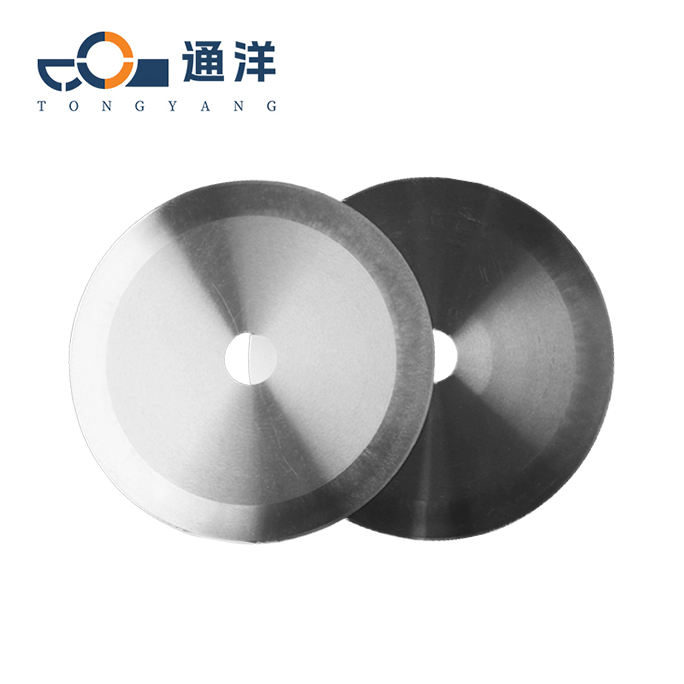

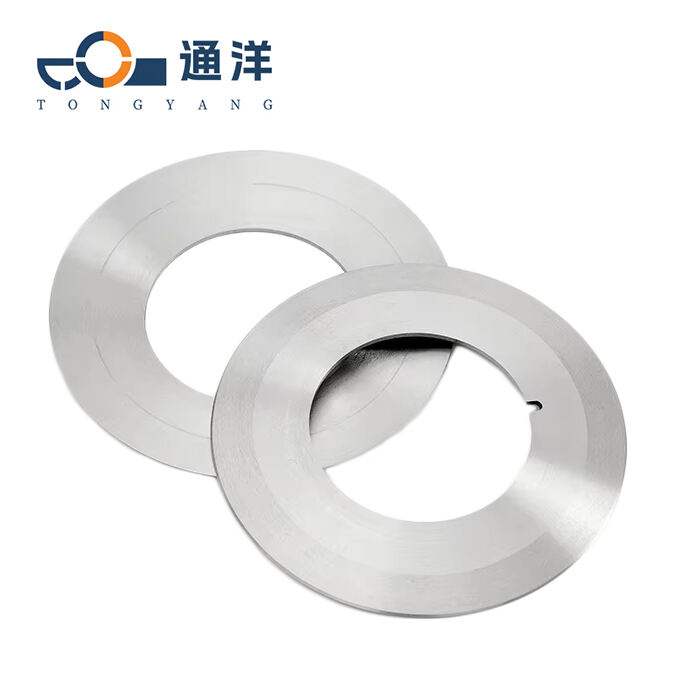

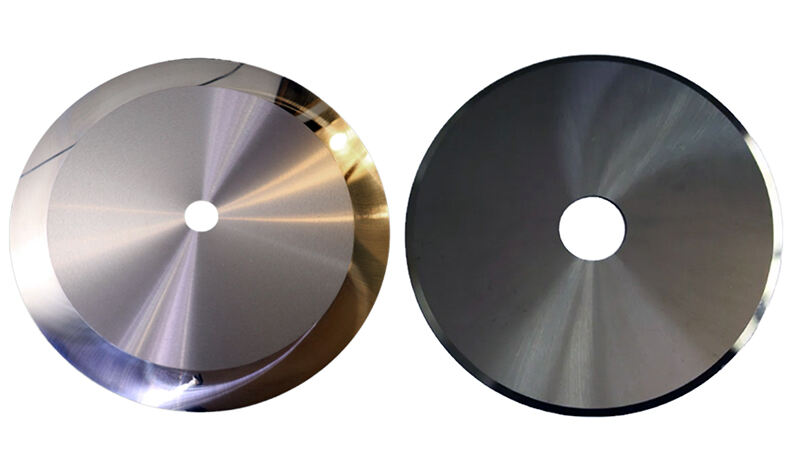

The differences between single-edge and double-edge

Single edge:When a single-edge cutting tool is cutting, the force is concentrated on one side of the cutting edge, which can generate a relatively large cutting force, making it suitable for deep cutting and powerful cutting. Due to the support on one side of the cutting edge, it is less likely to have situations such as edge chipping during the cutting process, and the durability of the cutting tool is relatively high.

Double edge: Since a double-edge cutting tool has cutting edges on both sides, it can be more flexible during cutting and can achieve bidirectional cutting. When performing some operations that require frequent changes in the cutting direction, a double-edge cutting tool does not need to be flipped frequently, which improves the cutting efficiency.

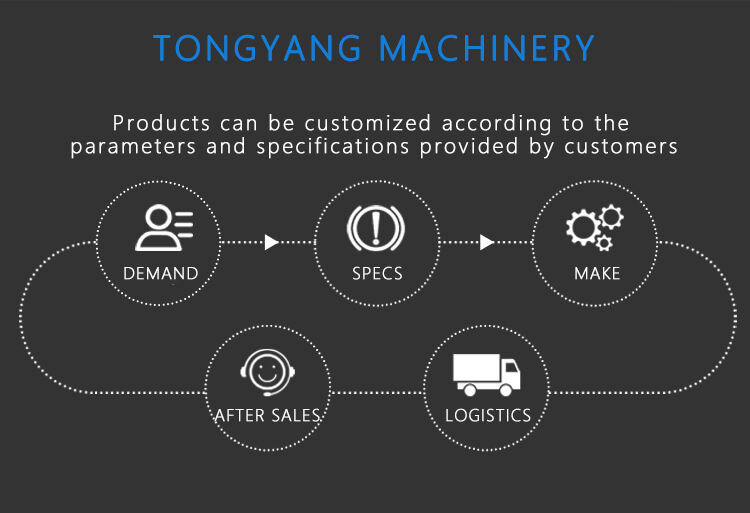

Our advantages

We support personalized customization services. You only need to provide information such as circular knife

parameters, machine types, and slitting materials, and we can produce according to your needs. The entire

process from production to delivery can be completed in as fast as 7 days.

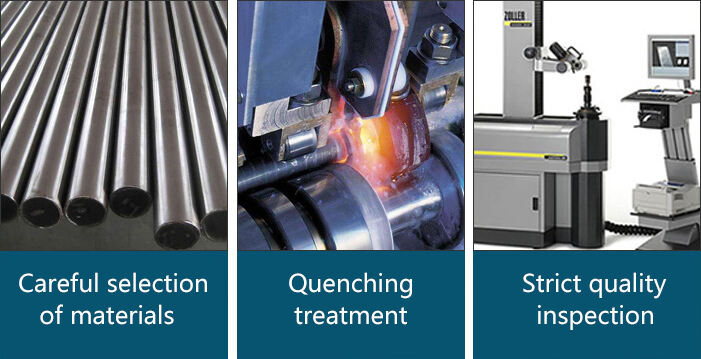

From material selection, production to quality inspection, we strictly follow the Standard Operating Procedure (SOP). In the material selection process, we have in-depth cooperation with top suppliers in the industry and carefully select high-purity and high-performance raw materials such as high-quality steel and cemented carbide to ensure that every industrial blade has excellent hardness, wear resistance, and red hardness from the source. During the production process, we use numerically controlled precision machining equipment and cutting edge manufacturing processes, implementing precision requirements throughout every single procedure.Whether it is the edge grinding of the blade, heat treatment strengthening or the shaping of the overall structure, we strive for perfection. In the quality inspection stage, we adopt a multi-dimensional inspection system, covering dozens of strict indicators such as hardness testing, sharpness inspection, wear resistance simulation, and dimensional accuracy calibration. Through the dual verification of professional instruments and manual rechecking, we prevent any defective products from entering the market.