Fundamentals of Blade Holder Stability in Precision Cutting

Vibration Reduction and Tool Longevity

Blade holder stability plays a pivotal role in reducing vibrations during precision cutting operations, ultimately extending tool longevity. When vibrations are minimized, the cutting tools experience less wear and tear, leading to longer service life and reduced replacement costs. Vibrations in cutting can be generated by dynamic forces such as machine imbalance and external disturbances like material inconsistencies. Technological advancements in blade holders have helped mitigate vibrations through the integration of composite materials and specialized designs, which offer enhanced damping capabilities. According to industry reports, tools with optimized vibration levels demonstrate significantly reduced wear rates. This reduction can be attributed to the effective absorption and dissipation of vibrational energy, which reduces stress on the cutting edges and helps maintain sharpness over an extended period.

Impact on Dimensional Accuracy

Dimensional accuracy in precision cutting is crucial, especially for industries like aerospace and automotive where exact specifications are necessary. The stability of blade holders directly impacts tolerances and surface finishes by ensuring consistent pressure and motion throughout the cutting process. Stable blade holders prevent deviation from desired measurements, thereby enhancing the quality of the output. Research has shown that stable holder systems significantly outperform unstable ones in maintaining part specifications, resulting in fewer errors and the need for rework. The automotive industry provides a case study where precision applications heavily rely on stable cutting conditions. Experts emphasize the importance of blade holder stability for achieving fine tolerances and smooth surface finishes, which are essential for high-performance components.

Rigidity Trade-offs in Modular Holders

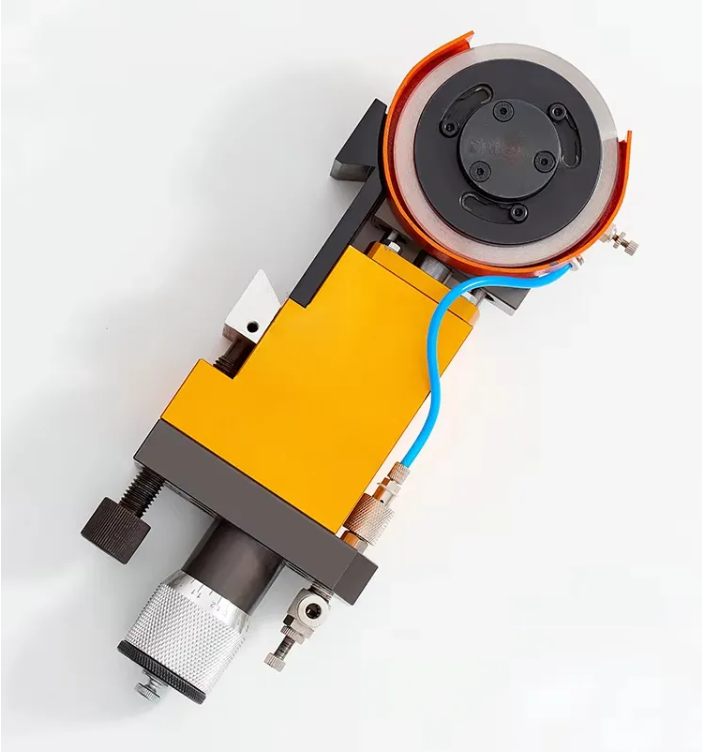

Modular toolholders offer a unique balance between flexibility and stability in precision cutting applications. These holders are highly advantageous because they are easy to configure, thus allowing quick and cost-effective tool changeovers. This adaptability makes them particularly suitable for industries where frequent adjustments to machining setups are necessary. A crucial advantage of modular holders is their ability to minimize replacement costs—when wear occurs, only the worn component needs to be replaced rather than the entire system.

Flexibility: Modular systems allow easy interchangeability and customization to suit specific cutting requirements, accommodating various blades and configurations.

Cost-Effective: Due to their design, only damaged or worn parts need replacement, reducing downtime and expense.

Industry Applications: Modular holders excel in environments requiring frequent setup changes, such as automotive and aerospace manufacturing.

However, the primary challenge with modular designs is their inherent mechanical flexibility, which can lead to reduced stability compared to integral systems. This could affect precision in cutting operations where high rigidity is necessary to minimize deflection and maintain accuracy.

Structural Advantages of Solid Toolholders

Solid toolholders, or integral systems, provide outstanding structural integrity and performance in high-stress cutting operations. Their construction offers consistent stiffness and minimal deflection, ensuring the tool remains stable and precise during demanding tasks. Made from robust materials like high-grade steel or tungsten carbide, solid toolholders withstand harsh conditions and prevent deformation, which is critical for maintaining precise tolerances and surface finishes.

In expert analyses, solid holders demonstrate superior performance metrics under high-stress conditions, outperforming modular systems in terms of rigidity. This makes them ideal for applications where precision and reliability are non-negotiable, such as in aerospace or heavy machinery manufacturing. For particular use cases, industries that handle challenging materials such as hardened steel greatly benefit from the use of solid toolholders due to their ability to maintain exact specifications and reduce tool wear.

Insert Selection for Stable Cutting Performance

PCBN vs. Carbide: Material Hardness Matching

Choosing between PCBN (Polycrystalline Boron Nitride) and carbide materials hinges on the specific application requirements and material hardness levels. PCBN is renowned for its superior hardness and thermal stability, especially suitable for cutting hard materials like ferrous metals with hardness levels exceeding 58 HRC. Carbide, on the other hand, is a more versatile choice for softer materials or applications below 50 HRC. Industry standards suggest CBN inserts are most effective when dealing with materials that test the upper hardness limits, providing the necessary stability and precision in demanding conditions. Numerous studies indicate that PCBN excels in precision cutting where high thermal resistance is paramount, though for materials under 50 HRC, carbide tends to be the economical choice without compromising effectiveness.

Various industry guidelines help inform these decisions by providing performance comparisons of these materials. For instance, Mitsubishi Materials offers specific PCBN grades like IB10H for continuous cutting and IB20H for interrupted cutting of hardened steel, showcasing the tailored effectiveness of PCBN in high-stress environments. By leveraging such insights and standards, users can optimize their material selection, ensuring efficient and stable cutting performance tailored to their operational demands.

Edge Geometry for Heat and Stress Distribution

Different edge geometries play a crucial role in managing heat distribution and stress profiles in cutting tools. The shape and sharpness of the edge significantly influence tool performance, helping to prevent premature wear and failure. For instance, sharp-edged tools ensure smoother cutting, reducing heat build-up and distributing stress evenly across the tool, which is critical in high-speed applications. Various geometries, such as rounded or chamfered edges, are used based on the specific cutting requirements—each offering distinct benefits in heat management and structural integrity.

Real-world applications underscore the effectiveness of specific geometries tailored to varying conditions. For example, the use of a convex 'V' formation in Mitsubishi's Tri-Lock modular systems helps eliminate side-to-side movement and reduces stress during intricate operations. Additionally, graphical illustrations can provide visual insights into these geometries, highlighting their impact in different cutting scenarios—thus guiding tool selection to optimize cutting performance while maximizing tool life. Understanding the interplay between edge geometry and cutting efficiency is essential for achieving high productivity and minimizing operational costs.

Thermal Expansion in High-Speed Cutting

Thermal expansion is a critical consideration in high-speed cutting operations, affecting both tool performance and part accuracy. In high-speed environments, the heat generated can lead to expansion of the cutting tool and workpiece, potentially resulting in deviations from intended tolerances. This issue is particularly pronounced with long cutting durations and high-speed rotations, which can increase temperature variances. Studies demonstrate that thermal fluctuations can reduce tooling lifespan by up to 50%, emphasizing the need for effective temperature management (The Importance of Blade Holder Stability in Cutting Operations). Implementing advanced cooling strategies, such as mist or cryogenic cooling, helps mitigate adverse thermal effects by regulating temperature, thereby maintaining stability and prolonging tool life.

Coolant Strategies for Temperature Control

Coolant strategies are essential for maintaining temperature control during machining processes. Selecting the right coolant—whether oil-based, water-soluble, or synthetic—depends on the material being machined and the specific operational context. Oil-based coolants, for instance, provide excellent lubrication and are ideal for intricate operations, while water-soluble options are effective in dissipating heat rapidly. Research indicates that effective coolant management can enhance tool life by up to 40% and improve surface finish quality. When implementing a coolant system, it is crucial to ensure consistent flow rates and pressure levels to optimize thermal regulation and machining efficiency. Strategic coolant application not only stabilizes temperatures but also improves overall operational outcomes.

Best Practices for Enhanced Stability

Overhang Minimization Techniques

Reducing tool overhang is pivotal because it directly impacts cutting vibration and enhances dimensional accuracy. By minimizing the distance between the tool's cutting edge and its supporting fixture, we can significantly diminish deflection and vibration, which are common in machining processes. Techniques to achieve this include using shorter tool lengths, which inherently offer greater rigidity, and employing clamping methods that distribute tool pressure evenly across the fixture. Scientific research, such as studies focusing on machining dynamics, often indicates a correlation between longer overhangs and increased tool wear rates, which adversely affect performance. Successful industrial applications highlight the effective use of modular holders and solid integral holders for minimizing overhang, demonstrating improved tool performance and longevity in high-stress environments like automotive manufacturing.

Precision Alignment Protocols

Precision alignment is essential for maintaining blade holder stability during cutting operations, ensuring optimal machining outcomes. Correct alignment reduces unwanted stress on the machine, facilitating accurate cuts and prolonging equipment life. Utilizing advanced techniques and tools, such as laser alignment systems and dial indicators, can provide the high degree of accuracy necessary for optimal blade placement. Several industry standards stress the importance of regular alignment checks, confirming their role in improved operational efficiency and reduced machine downtime. Consistent application of these protocols has been shown to lead to more predictable and reliable machining results, especially in settings requiring high precision, such as aerospace or automotive part manufacturing.

FAQ Section

What role does blade holder stability play in precision cutting?

Blade holder stability reduces vibrations and extends tool longevity, essential for precision cutting operations.

What are the benefits of modular toolholders?

Modular toolholders offer flexibility, cost-effectiveness, and suitability for frequent setup changes, though they may have reduced stability compared to solid holders.

Why are solid toolholders preferred for high-stress operations?

Solid toolholders provide superior rigidity and structural integrity, ensuring precision and reliability during demanding cutting tasks.

How do PCBN and carbide materials differ?

PCBN is suitable for cutting hard materials due to its superior hardness, while carbide is versatile for softer materials and cost-effective under lower hardness levels.

Why is coolant strategy important?

Coolant strategy is crucial for temperature control during machining, enhancing tool life and improving surface finish quality.