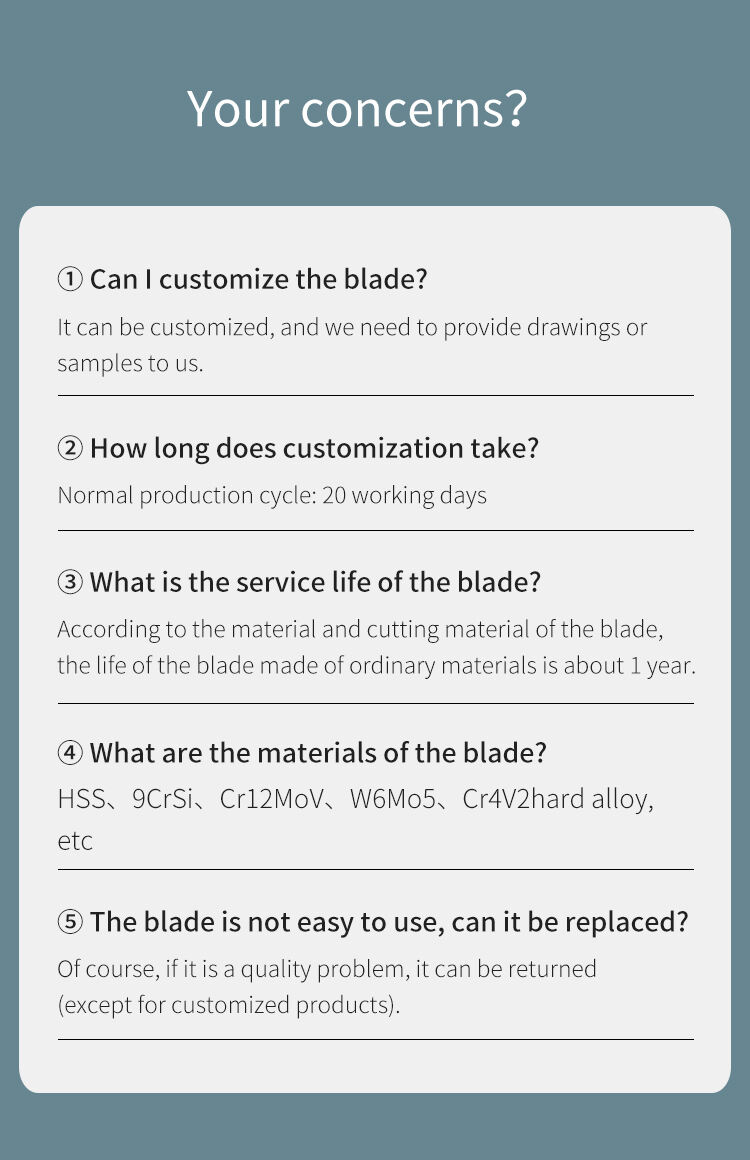

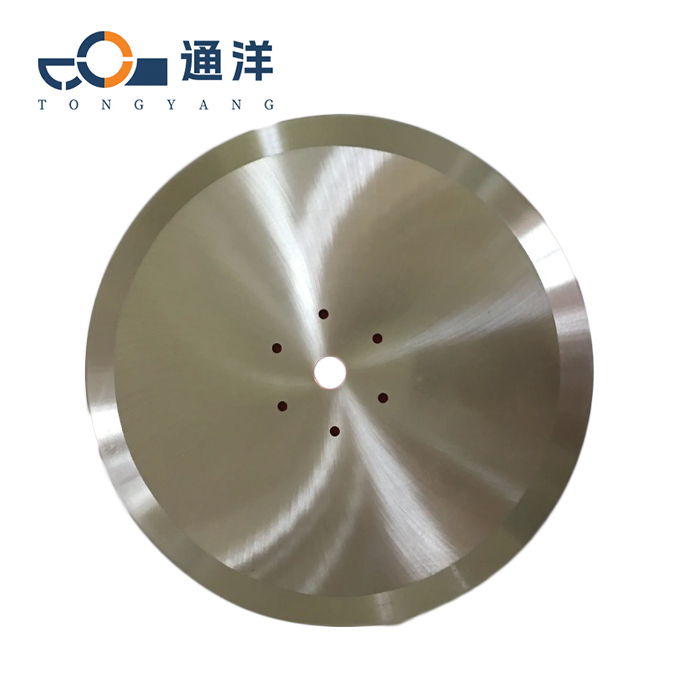

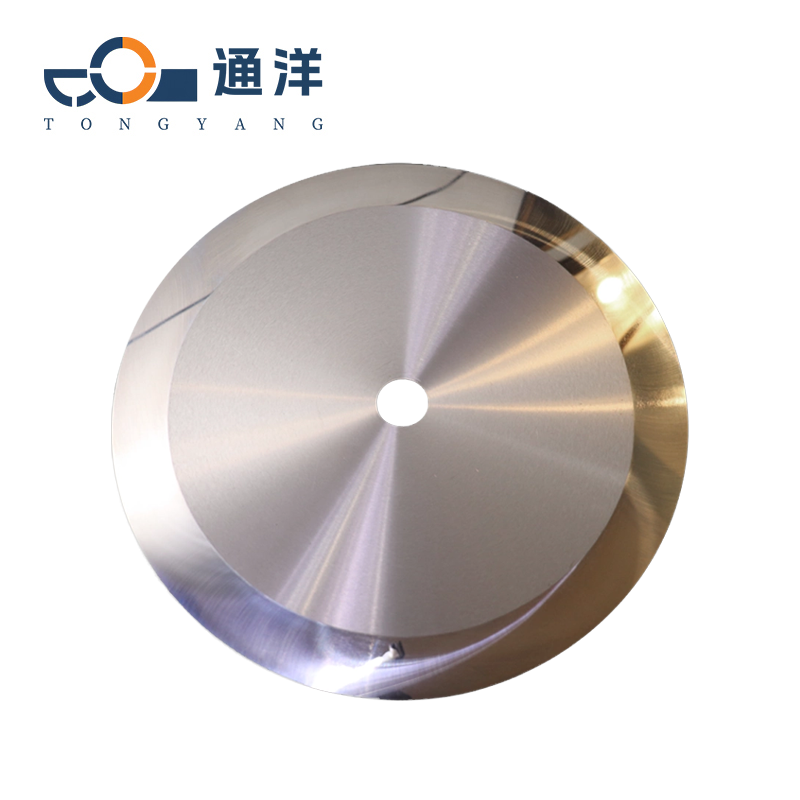

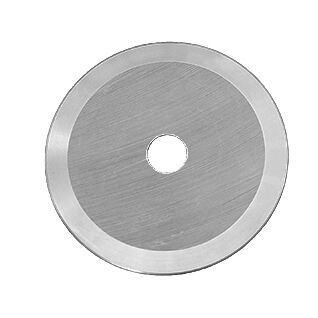

Tape cutting blade

Tape slitting machine blades are specialized cutting tools for the slitting process in tape production lines, mainly used to slit large rolls of tape (master rolls) into small rolls of specified widths (sub-rolls). Their core function is to ensure smooth edges, burr-free surfaces, no stretching deformation, and non-stick properties through high-precision cutting, while balancing slitting efficiency and tool life. Blades of different materials and specifications are custom-selected based on the differences in tape materials (such as BOPP, PET, masking paper, foam, etc.) and thickness.

- Overview

- Recommended Products

Common materials and applications

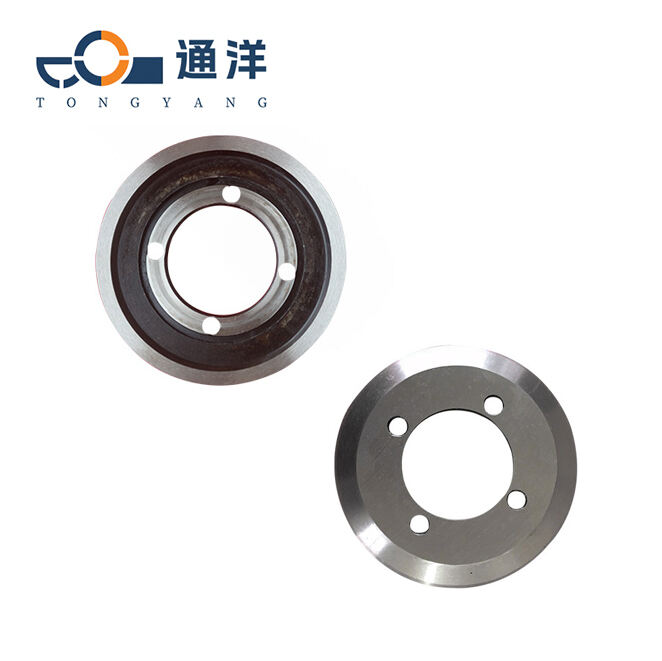

Tool steel

Material characteristics:It has relatively high hardness and strength, as well as good wear resistance and toughness. The cost is relatively low, and it has good processing performance. It can be made into various shapes and sizes of cutting tools, which can meet the installation requirements of different tape cutting equipment.

Application:In the production of ordinary sealing tape and daily product packaging, the circular tape cutting knives made of tool steel can work stably, provide good cutting effects, and have a high cost performance ratio.

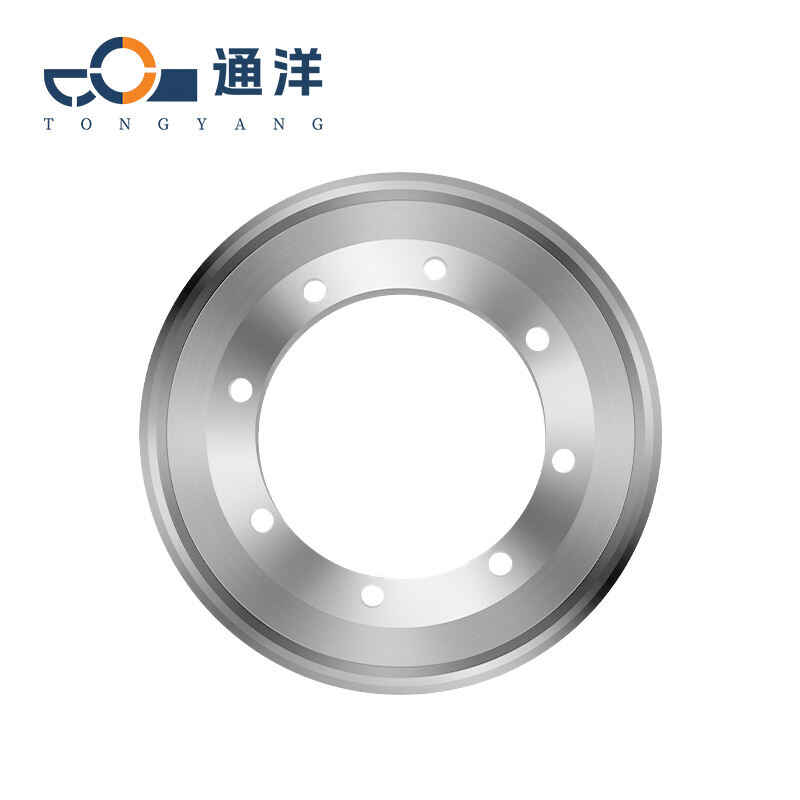

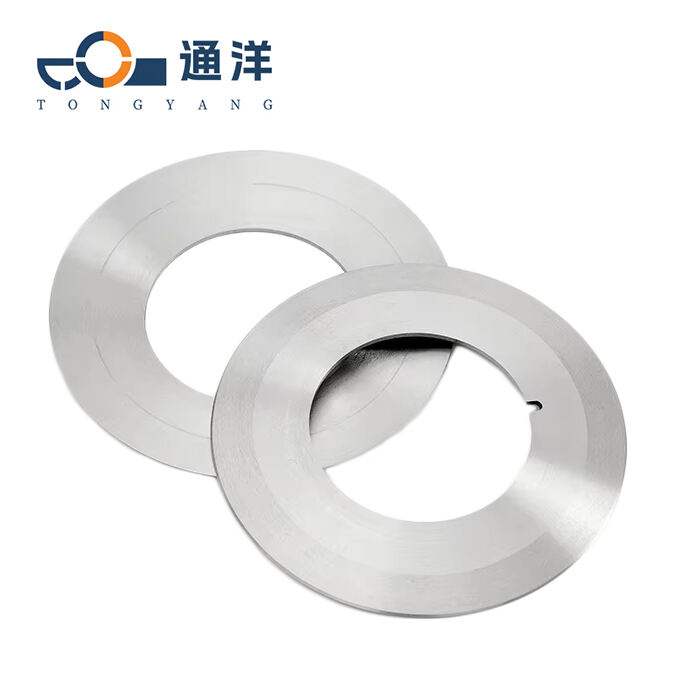

Cemented carbide

Material characteristics:It has extremely high hardness and excellent wear resistance, and is not prone to deformation. It can maintain good cutting performance during high-speed cutting and long-term continuous operation.

Application:The circular cutting knife made of cemented carbide has extremely high hardness, strong wear resistance and is not prone to deformation. It can maintain good performance during high-speed and long-term continuous cutting. It is suitable for scenarios with strict requirements for cutting precision and efficiency, such as the production of high-precision electronic tapes. It can also be used to cut special tapes like carbon fiber tapes, easily handling high-hardness materials.

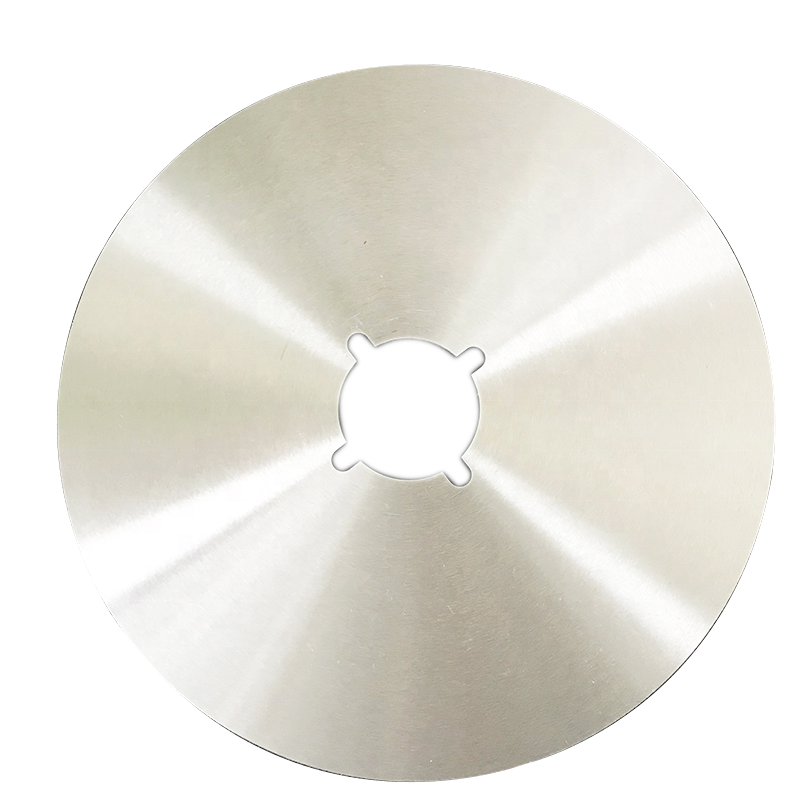

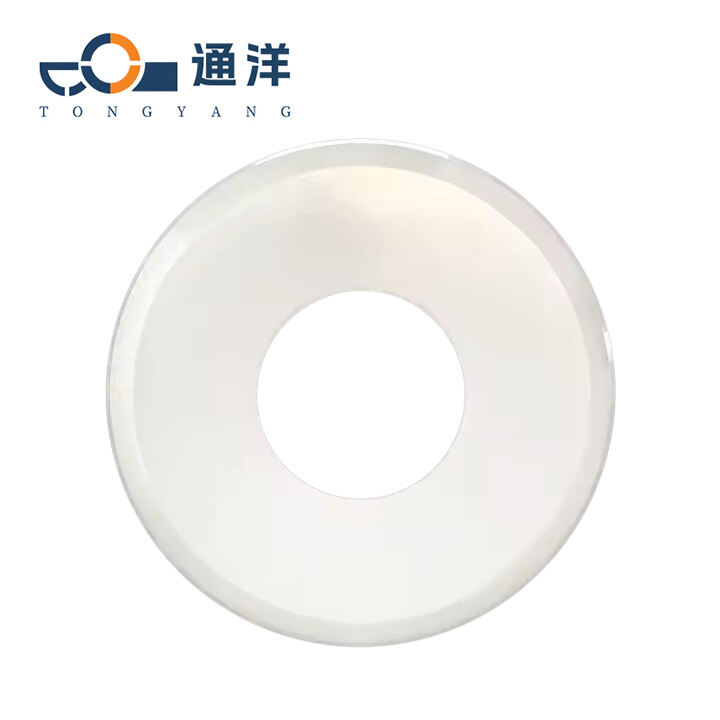

Stainless steel

Material characteristics:It has excellent corrosion resistance, being able to resist the erosion of water, chemical substances, etc., and is not prone to rust. At the same time, it has a certain degree of toughness and strength, and can withstand a certain level of cutting pressure and impact force.

Application:The stainless steel circular tape cutting knife, with its excellent corrosion resistance, is widely used in the packaging processes of industries with high hygiene requirements such as the food and pharmaceutical industries. It can prevent rust from contaminating products and ensure product safety. At the same time, in environments such as the packaging workshops of chemical products that are humid or at risk of chemical corrosion, it can also rely on its corrosion resistance advantage to ensure the normal use and long service life of the cutting tool.

Material customization

We also provide customization services for other materials

For each customized product, the material inspection will be carried out by a spectrometer.

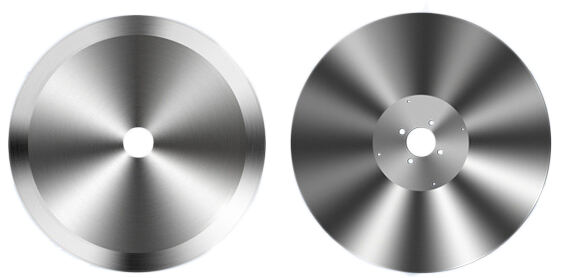

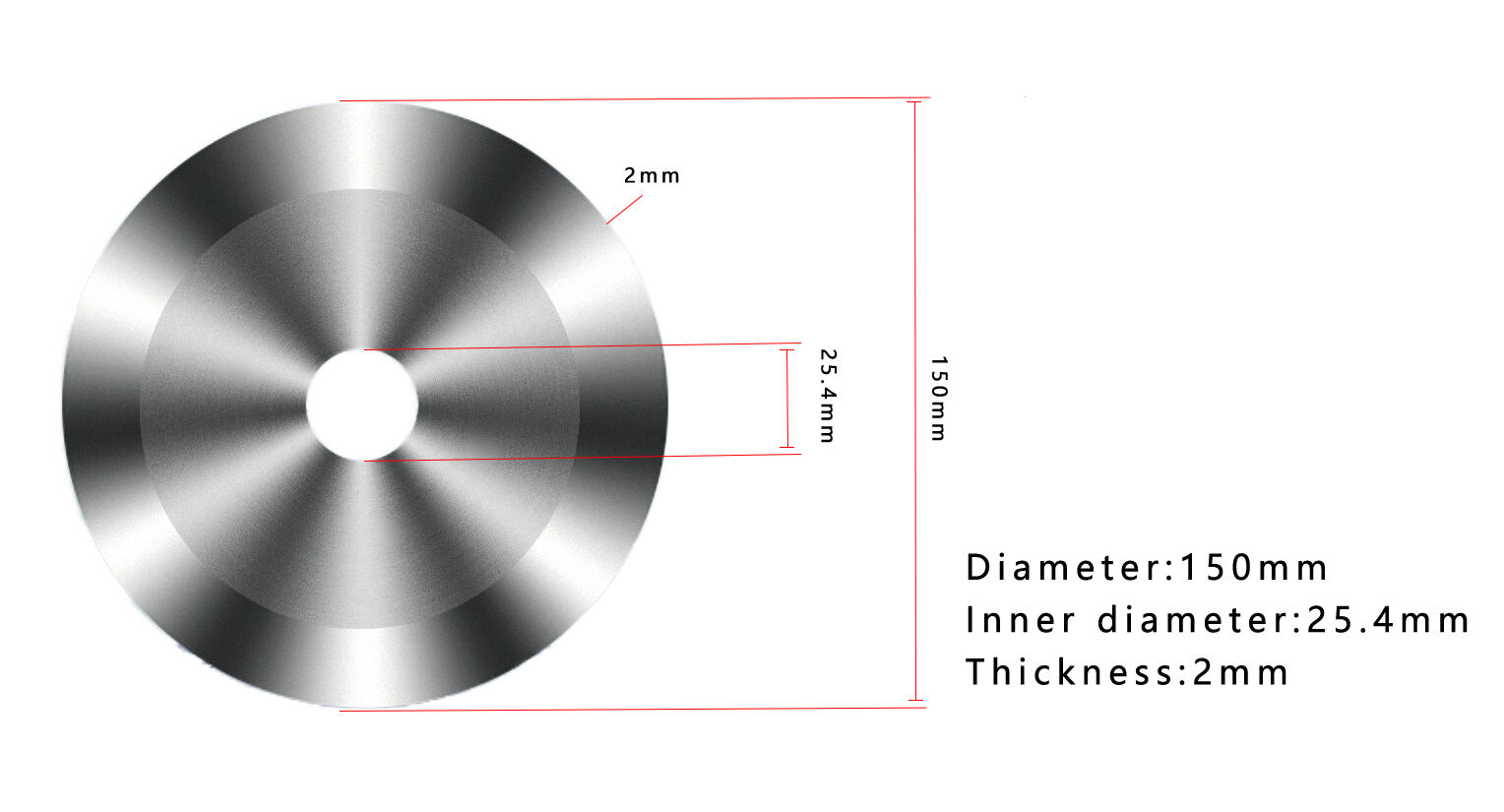

Common specifications

| Diameter | Inner diameter | Thickness | Application |

| 70mm | 40mm | 1mm | With a relatively small size and thin thickness, it is usually used for cutting plastic wrapping paper |

| 76mm | 25.4mm | 1.2mm | Increasing the thickness enables it to slit the tape rolls, and it can perform the slitting stably |

| 110mm | 60mm | 2mm | With a diameter of 110mm, it can also cut thicker tape rolls stably and is capable of working at a high speed |

| 150mm | 25.4mm | 2mm | It can be used for slitting sealing tapes, and is suitable for conditions where the precision requirements are not particularly high and high-speed production is needed |

| 250mm | 25.4mm | 2.5mm | It is often used for slitting and trimming plastic daily products. |

| 300mm | 25.4mm | 3mm | Cut thicker strips in bundles, such as adhesive tape bundles, non-woven fabric bundles, paper rolls, etc. |

| 600mm | 32mm | 3mm | Cut thick bundles, trim rubber products, and slit toilet paper rolls. |

Please measure the specifications that are suitable for the mechanical blade before customization(Parameters such as diameter, inner diameter, thickness, and punching)

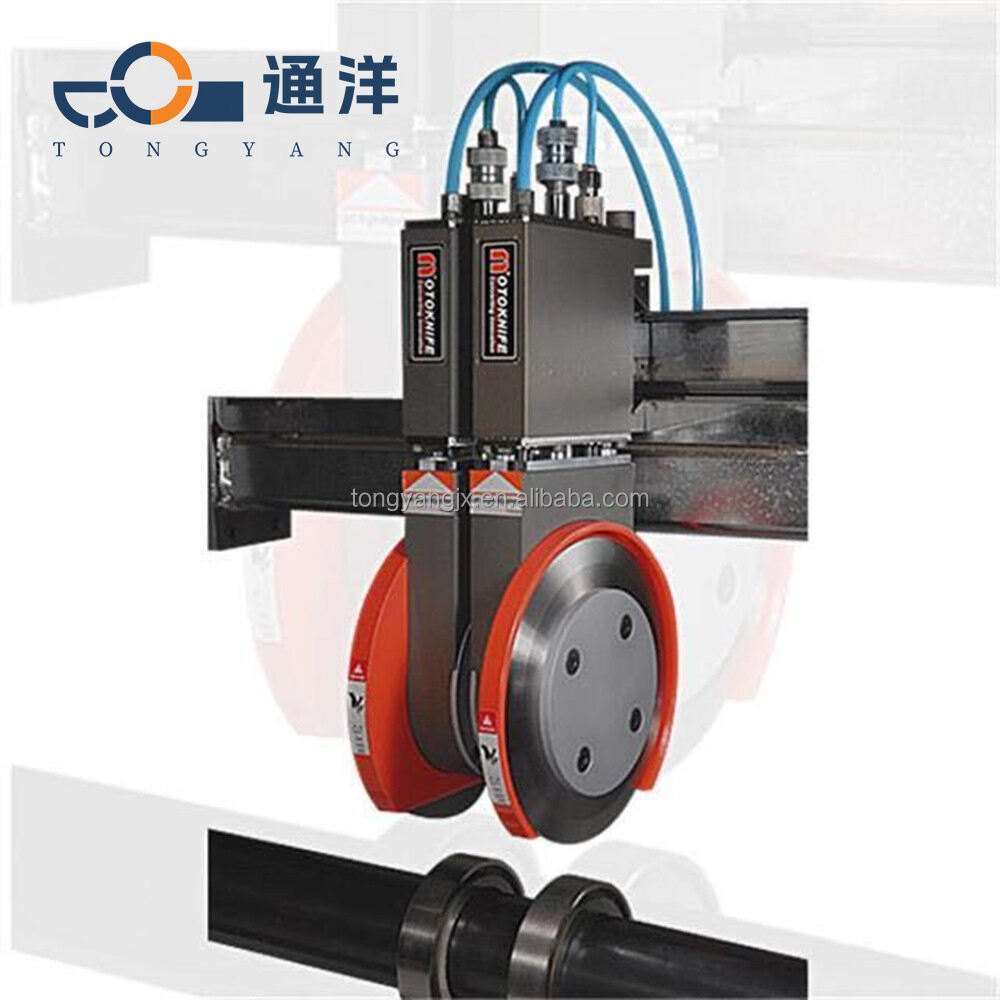

Our advantages

The cutting tools we produce are compatible with various types of slitting machines on the market. All of them have passed strict on-machine tests, ensuring stable and efficient operation. Whether it is the slitting of materials such as adhesive tapes, non-woven fabrics, rubber products, or toilet paper rolls, precise and smooth cutting can be achieved, providing a reliable guarantee for your production and processing.

To ensure the quality of our cutting tools, we have established a rigorous and comprehensive quality inspection system that covers the entire process and adheres to high standards.In the raw material stage,we conduct multi-dimensional inspections such as component analysis and initial hardness testing on raw materials like steel and cemented carbide. Only materials that meet our strict standards are allowed to enter the factory.During the production process, we set up multiple sampling inspection nodes for key processes. Using high precision inspection equipment, we accurately measure details such as the cutting edge angle and surface roughness of the cutting tools, promptly identifying and correcting any production deviations.At the finished product stage, we carry out all-round performance tests. In addition to testing core indicators such as hardness,wear resistance, and dimensional accuracy, we also conduct on-machine tests simulating high-intensity working conditions. The cutting tools are operated continuously for several hours, and we monitor their cutting stability and wear conditions under high-speed and heavy-load conditions.Through these layers of strict inspection, we ensure that every cutting tool leaving the factory can demonstrate stable and reliable quality in actual use, providing a solid guarantee for our customers' production needs.

Reliable Logistics Assurance: We ensure that your customized products are carefully packaged and safely transported to the designated location. Timely tracking and communication during the logistics process keep you informed of every step of the progress.