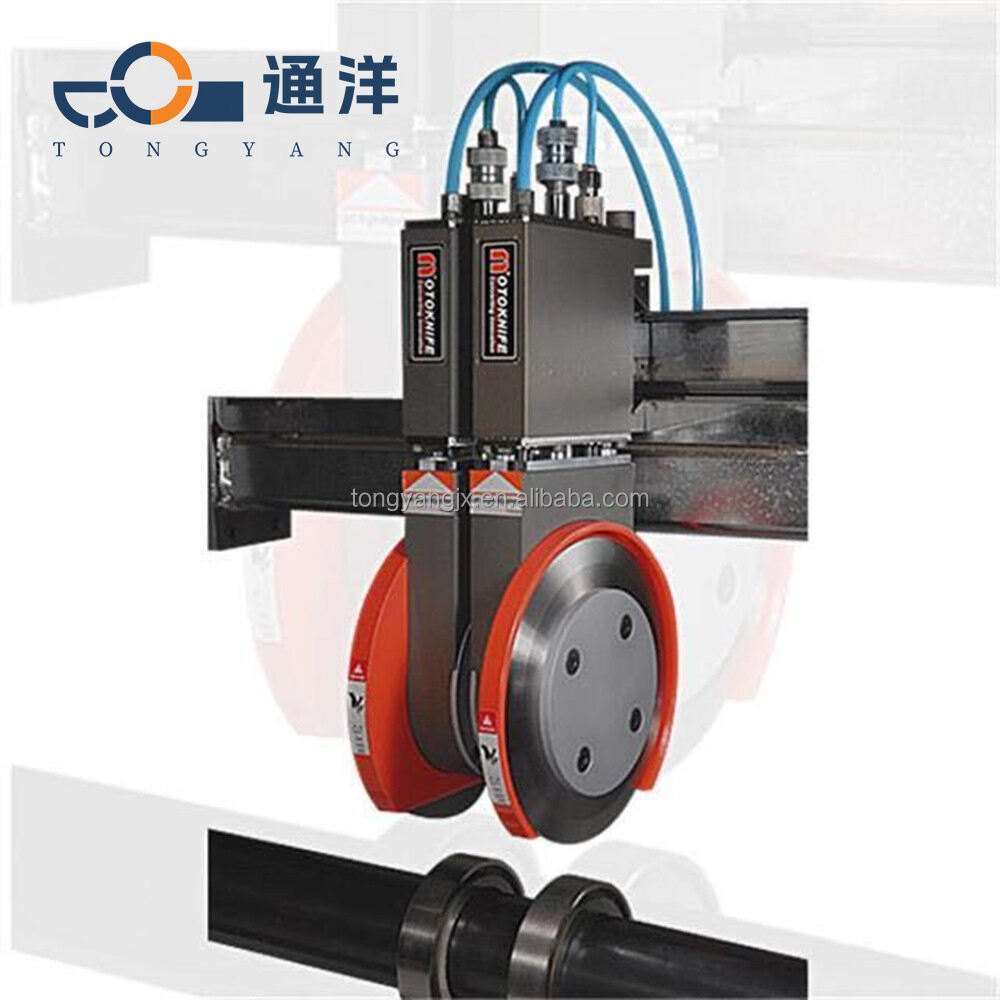

Non-woven slitting knife

Slitting machine blades, commonly used for slitting non-woven fabrics and synthetic fibers, can ensure uniform performance of cutting tools even in large sizes. The blade materials and specifications can be adjusted according to different cutting materials.

- Overview

- Recommended Products

Common materials and applications

High-speed steel

Material characteristics:High speed steel material has high wear resistance and long service life when cutting materials The tool can maintain good cutting performance even at high temperatures Regular maintenance is required.

Application:Commonly used in high-speed slitting machines, suitable for large-scale production (such as slitting non-woven fabrics, synthetic fabrics, etc.)

SKD-11

Material characteristics:It can resist wear and corrosion, which can extend the service life of the cutting tool. At the same time, it can ensure that the cutting tool can also obtain uniform performance in larger sizes.

Application:It is quite common when cutting and processing materials with relatively high hardness,such as non-woven fabric rolls, natural cotton and linen fabrics, car floor mats, and leather.

Tungsten

Material characteristics:It has excellent wear resistance, can maintain the sharpness of the blade during long-term operation, and has a high cutting precision. It is not prone to deformation during the cutting process, ensuring the stability and accuracy of the cutting.

Application:It is often used for high-precision slitting applications, such as ultra-thin stainless steel sheets, carbon fiber materials, ceramic films, high-end fabrics, natural leather, etc. Tungsten steel slitting knives are commonly used tools for various materials with high precision requirements.

Chromium steel

Material characteristics:The presence of chromium endows chromium steel with good corrosion resistance, enabling it to be used in some rather harsh working environments. It is not prone to rust and corrosion, thus extending the service life of the cutting tool.

Application:Due to its excellent corrosion resistance characteristics, it is often used in dyeing factories for cutting fabrics and in the manufacturing of daily necessities.

Material customization

We also provide customization services for other materials

For each customized product, the material inspection will be carried out by a spectrometer.

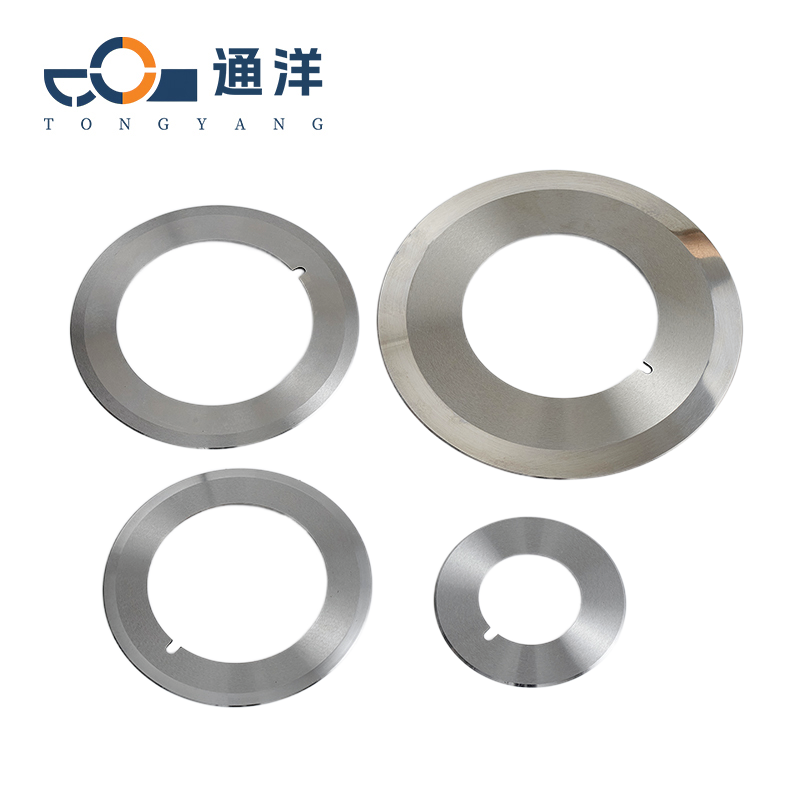

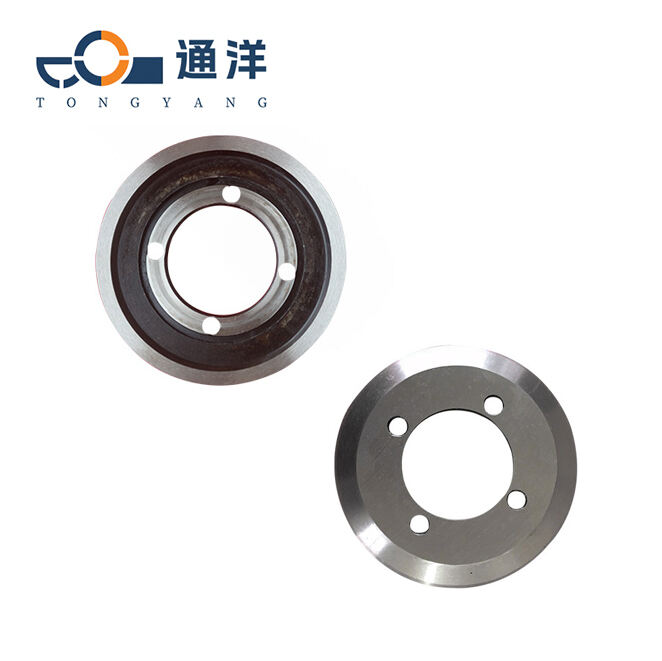

Common specifications

| Diameter | Inner diameter | Thickness |

| 61mm | 40mm | 1mm |

| 68mm | 40mm | 1mm |

| 68mm | 46mm | 0.5mm |

| 70mm | 40mm | 1mm |

| 75mm | 45mm | 1mm |

| 90mm | 60mm | 1.2mm |

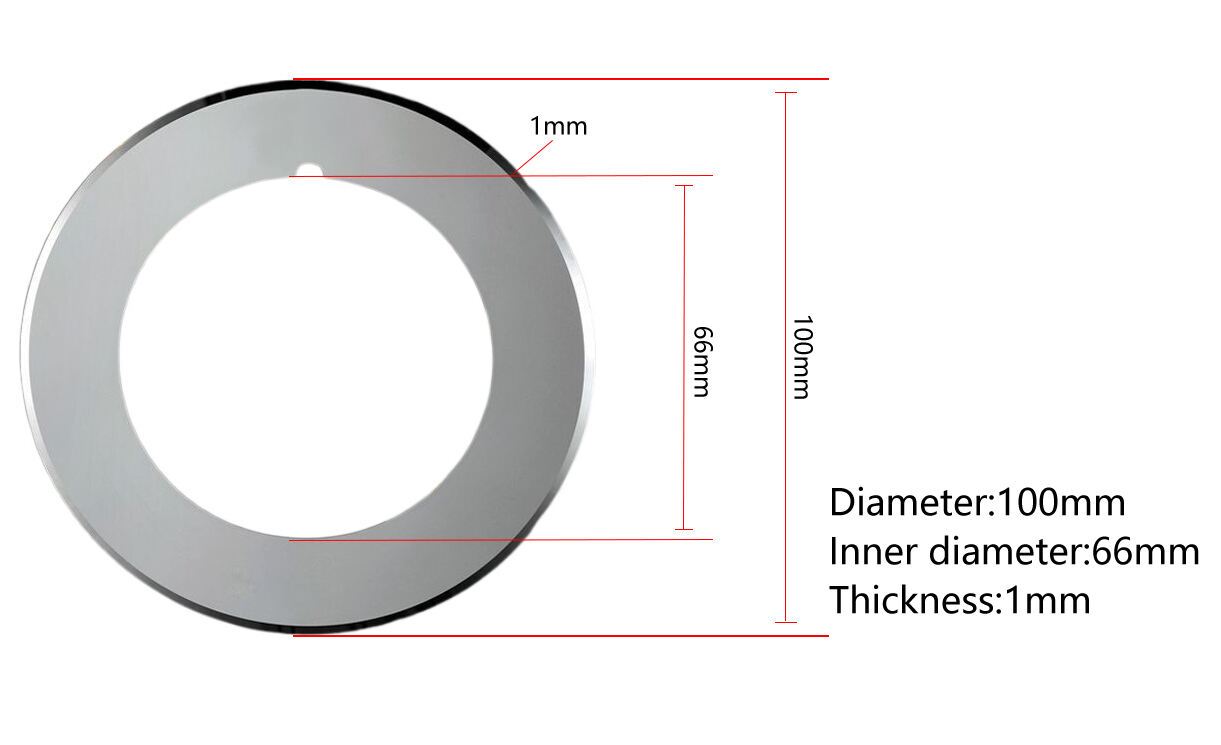

| 100mm | 66mm | 1mm |

| 100mm | 75mm | 1mm |

These specification sizes are applicable to the fine slitting scenarios of non-woven fabrics and single-layer fabrics. With the relatively small specification parameters, the equipment can achieve high-precision cutting.Coupled with the design of an ultra-thin blade body, it can ensure that the cutting surface is flat and smooth,effectively avoiding problems such as frayed edges and pilling, and providing a reliable guarantee for high quality fabric processing.

![]()

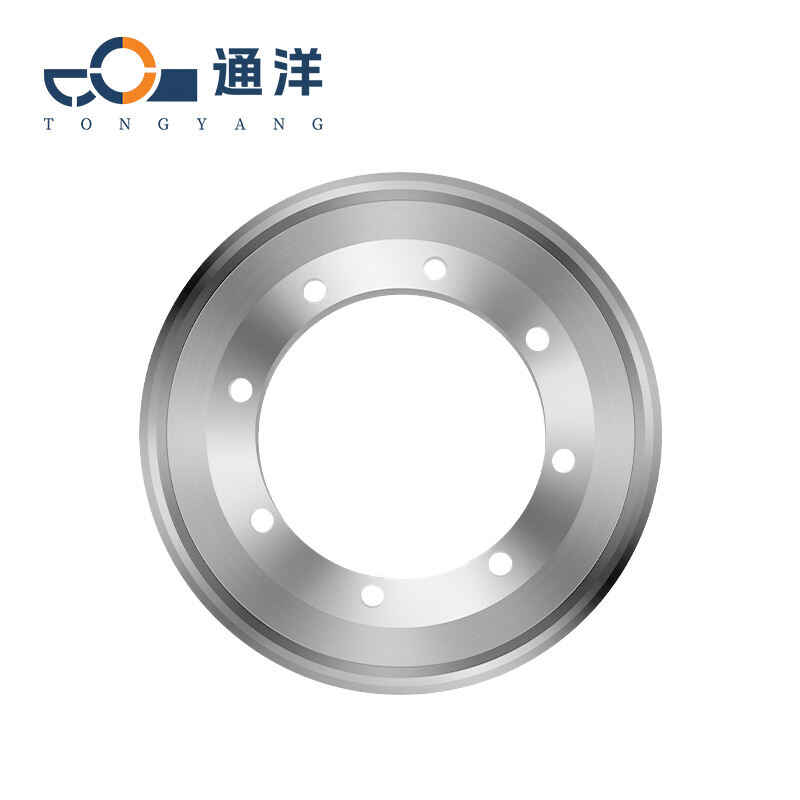

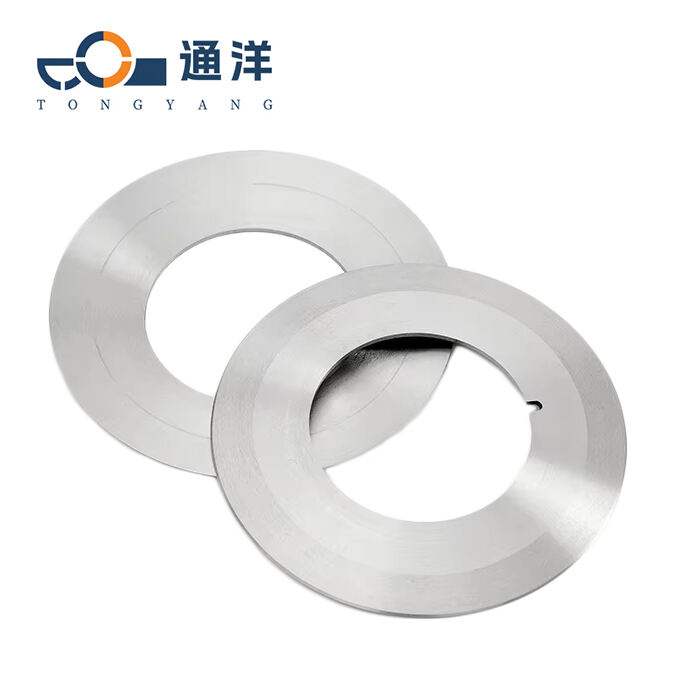

| Diameter | Inner diameter | Thickness |

| 105mm | 66mm | 1.2mm |

| 105mm | 70mm | 1.2mm |

| 108mm | 47mmm | 7mm |

| 118mm | 63mm | 8mm |

| 130mm | 80mm | 1.2mm |

| 130mm | 90mm | 1.2mm |

| 140mm | 90mm | 1.2mm |

| 150mm | 80mm | 2mm |

These larger specification sizes are particularly suitable for the cutting operations of single layer leather, hard fabrics, and paper tubes. With excellent mechanical properties and structural design,they can achieve efficient and stable cutting effects, and have significant advantages in scenarios of large-scale continuous production. In order to ensure the maintenance of high-precision cutting quality over the long term, it is recommended to conduct professional maintenance and replacement of the cutting tools regularly, so as to extend the service life of the equipment and ensure· production efficiency and processing quality.

Please measure the specifications that are suitable for the mechanical blade before customization(Parameters such as diameter, inner diameter, thickness, and punching)

Our advantages

Each in-stock model will go through a strict on-machine testing process. By simulating real cutting scenarios, a comprehensive inspection will be carried out on key indicators such as the sharpness,cutting precision, and stability of the blade to ensure that each blade can achieve excellent cutting results.

Customize

Precise Specification Adherence: Our experienced engineers and technicians are proficient in handling various specification requirements. Once your requirements are clear, we ensure that every parameter, from the dimensions of components to the performance indicators of the entire machine,is strictly adhered to. This precision guarantees that the final customized product not only meets but often exceeds your expectations.

Efficient Production Execution: Equipped with advanced manufacturing equipment and streamlined production processes, we can promptly transform the approved specifications into high - quality products.The optimized production workflow minimizes delays, ensuring that you receive your customized machinery within the promised time frame.

Comprehensive After - sales Support: Our service commitment extends beyond delivery. Our after sales team is always ready to assist you. Whether it's maintenance guidance, spare parts supply, or troubleshooting, we provide prompt and effective support to ensure the long term smooth operation of your customized equipment.

All products are required to undergo a strict notch detection process. From the raw materials to the finished products, the entire process is monitored. Multiple detection methods are employed to accurately

identify potential defects, ensuring that the quality of each product reaches the highest standard.

Reliable Logistics Assurance: We ensure that your customized products are carefully packaged and safely transported to the designated location. Timely tracking and communication during the logistics process keep you informed of every step of the progress.