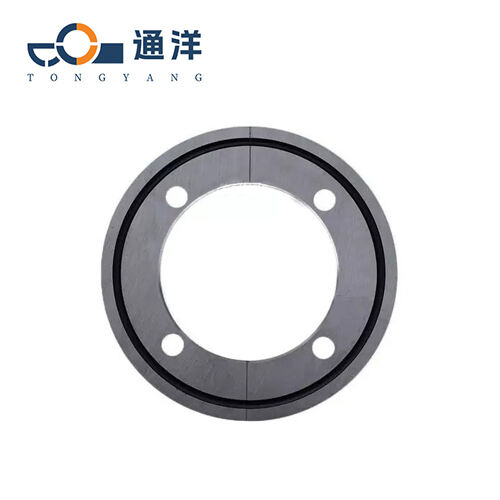

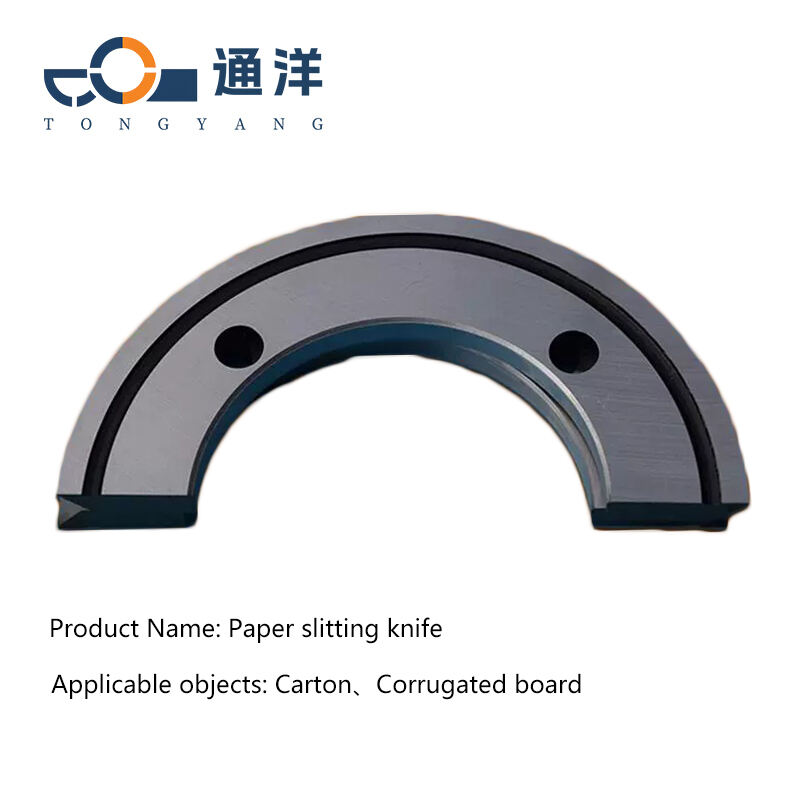

Corrugated paper cutting knife

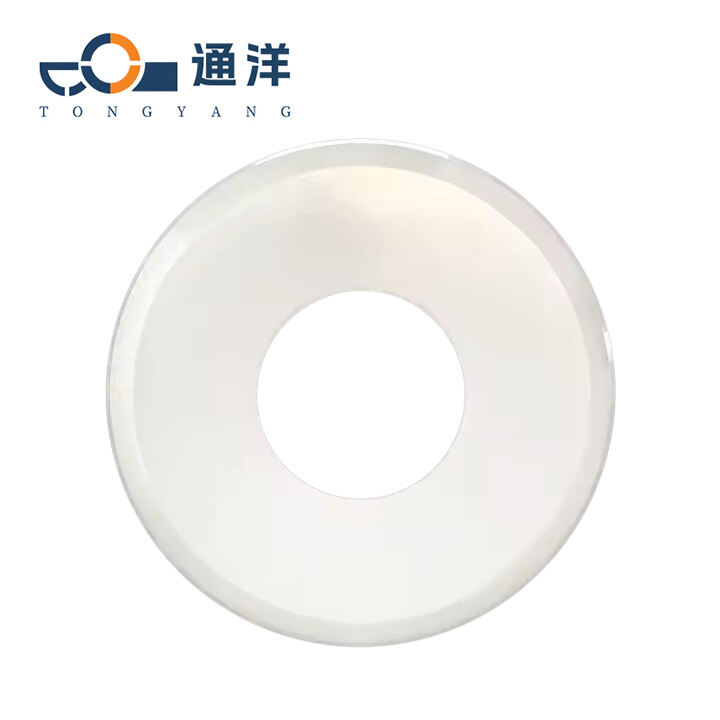

The semicircular cutting knife is a professional cutting tool with a semicircular arc edge. The arc of the blade is usually a 180° semicircle or a semi-circular structure of 90°-170°, mainly used for precise processing of arc, curve or circular incisions. The tool body is mostly made of metal materials (such as high-speed steel and cemented carbide), and some high-end models use ceramic or diamond coatings. Its core advantage lies in realizing curve cutting that traditional straight knives cannot complete through the arc edge, which is widely applied to the processing of flexible materials such as leather, fabric, rubber and paper, as well as some hard materials.

- Overview

- Recommended Products

Materials and Their Applications

High-speed steel material

Material characteristics:It has high hardness, high wear resistance and good toughness, and can maintain good cutting performance during the high-speed cutting process, and it is not easy to have problems such as edge chipping.

Application:It is suitable for the slitting of various types of corrugated paper and the manufacturing of cartons.Especially for the processing of medium and high-end corrugated paper, it can ensure the slitting accuracy and quality. The tool life is relatively long, and it can be used in the slitting process of single machine slitting equipment as well as linked production lines.

Cemented carbide material

Material characteristics:It has extremely high hardness and excellent wear resistance, as well as good high temperature resistance and corrosion resistance. Its cutting edge can maintain a sharper state, resulting in high slitting efficiency.

Application:It is commonly used in high-speed and high-precision corrugated paper slitting production lines.It performs excellently in large-scale and high-efficiency production environments, and can adapt to long-term continuous operation. It has a remarkable slitting effect on corrugated paper and cartonswith high-strength and high-quality requirements, such as the automated production lines of large carton factories.

Coated tool material

Material characteristics:A single layer or multiple layers of high-performance coatings, such as titanium nitride(TiN), titanium aluminum nitride (TiAlN), etc., are coated on the tool substrate. These coatings can improve the performance of the tool, such as hardness, wear resistance, lubricity, and oxidation resistance.

Application:It is widely used in various corrugated paper slitting scenarios. Coated tools can effectively reduce the cutting force and cutting temperature, decrease the friction between the tool and the corrugated paper, improve the slitting quality, and at the same time extend the service life of the tool. They are particularly suitable for the processing of corrugated paper with high requirements for the slitting surface quality.

Precautions for Customizing Tools of Other Materials

Clarify the usage requirements:It is necessary to clarify the uses of the cutting tools (such as cutting and slicing)and the characteristics of the processing materials (hardness, toughness, thickness, etc.) The requirements for the materials of the cutting tools vary significantly when cutting corrugated cardboard and cartons of different qualities. At the same time, the processing precision should be taken into account, and high-precision processing requires the cutting tools to have good dimensional stability and sharpness.

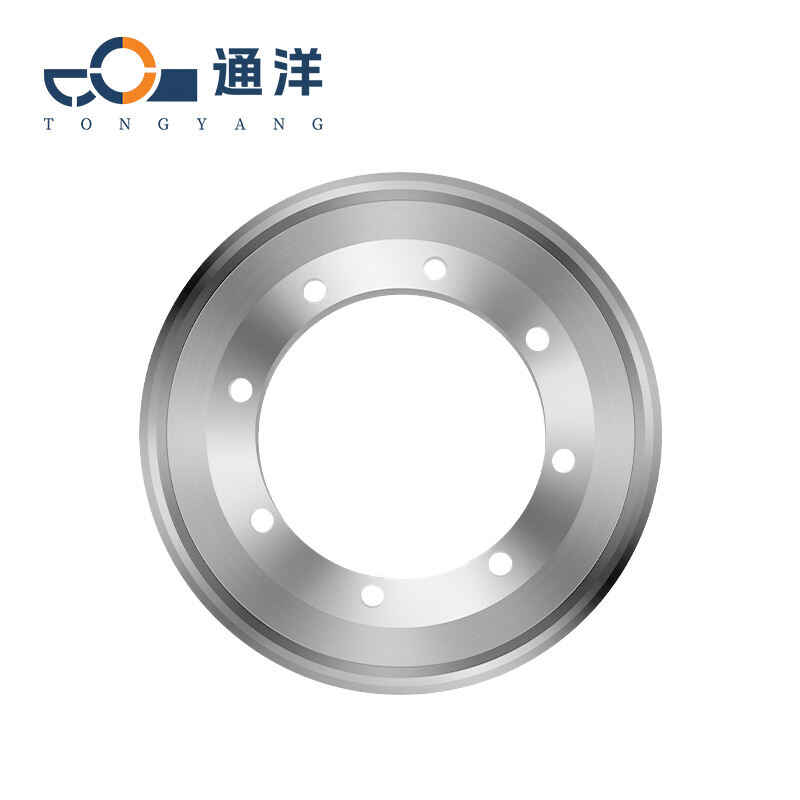

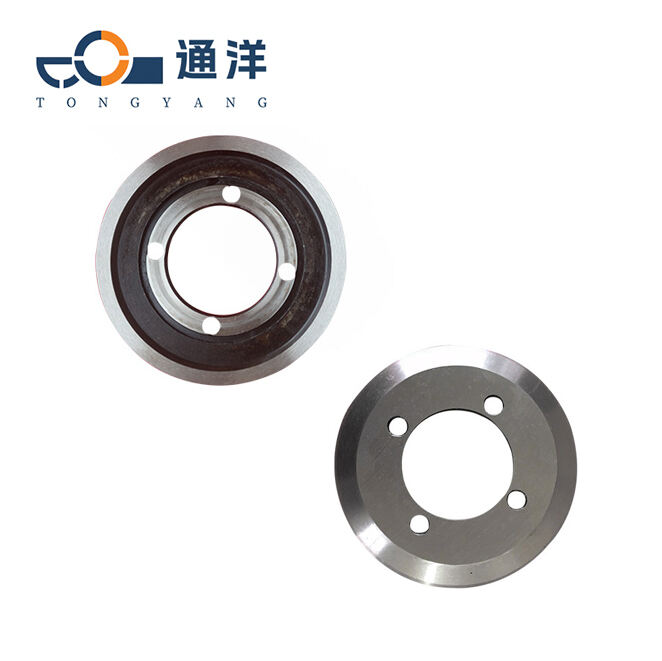

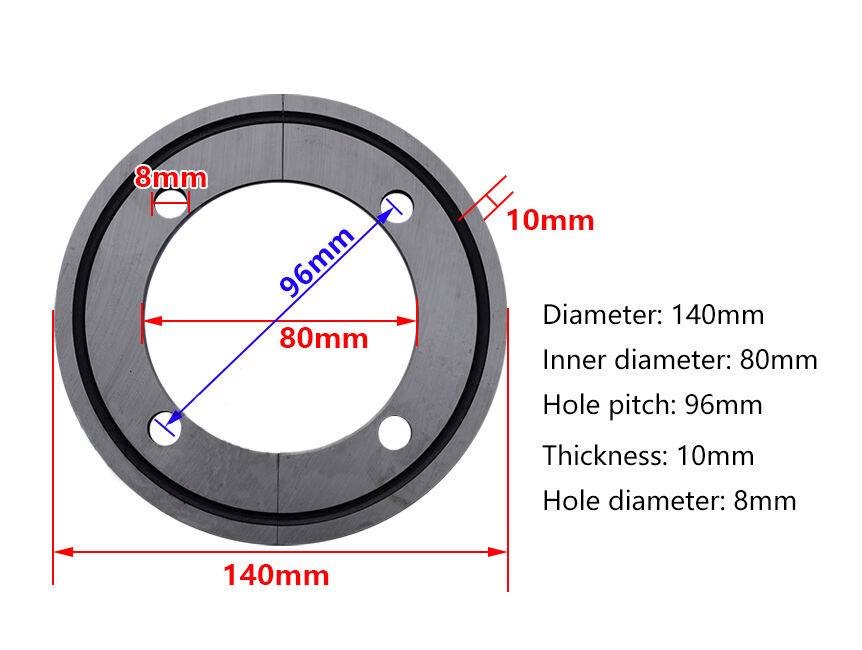

Common specifications

| Diameter | Inner diameter | Thickness | The number of holes | Hole diameter | Hole spacing |

| 140mm | 80mm | 10mm | 4 | 8mm | 96mm |

| 140mm | 85mm | 10mm | 6 | 8mm | 100mm |

| 155mm | 85mm | 10mm | 4 | 12mm | 105mm |

| 156mm | 95mm | 10mm | 6 | 12mm | 115mm |

| 160mm | 90mm | 10mm | 6 | 10mm | 108mm |

| 160mm | 95mm | 10mm | 4 | 12mm | 113mm |

| 165mm | 95mm | 10mm | 4 | 12mm | 113mm |

| 190mm | 120mm | 10mm | 4 | 12mm | 140mm |

Precautions for Customizing Other Specifications

When customizing, attention should be paid to the number of holes and the measurement of the hole spacing.

Please refer to the actual measurement.

Cutting advantages

Cutting precision

The arc-shaped design of the semi-circular knife can better fit the curve of the corrugated paper, enabling it to cut more precisely along the predetermined cutting line during the cutting process, reducing errors.It is especially suitable for cutting some corrugated paper products with arcs or curved shapes, such as circular packaging boxes, arc-shaped display shelves of cartons, etc. It can ensure that the edges after cutting are neat and smooth, improving the appearance quality of the products.

High yield rate

When the semi-circular knife is cutting, the contact area between the blade and the material is relatively small, and the pressure of the blade on the material is relatively concentrated. It can cut into the material with less force, thereby reducing the damage to the material and lowering the probability of problems such as defective products occurring during the cutting process. This is conducive to maintaining the high-quality output of products.

The service life of the cutting tool is long

Due to the design of its arc-shaped blade, the blade of the semi-circular knife wears more evenly, and there will be no phenomenon of excessive wear in a certain part, thus extending the service life of the

cutting tool Materials such as high-speed steel and cemented carbide are usually used. These materials have high hardness wear resistance and toughness, and can withstand the impact force and friction force during the cutting process further improving the durability of the semi-circular knife, reducing the frequency of tool replacement, and lowering the production cost.

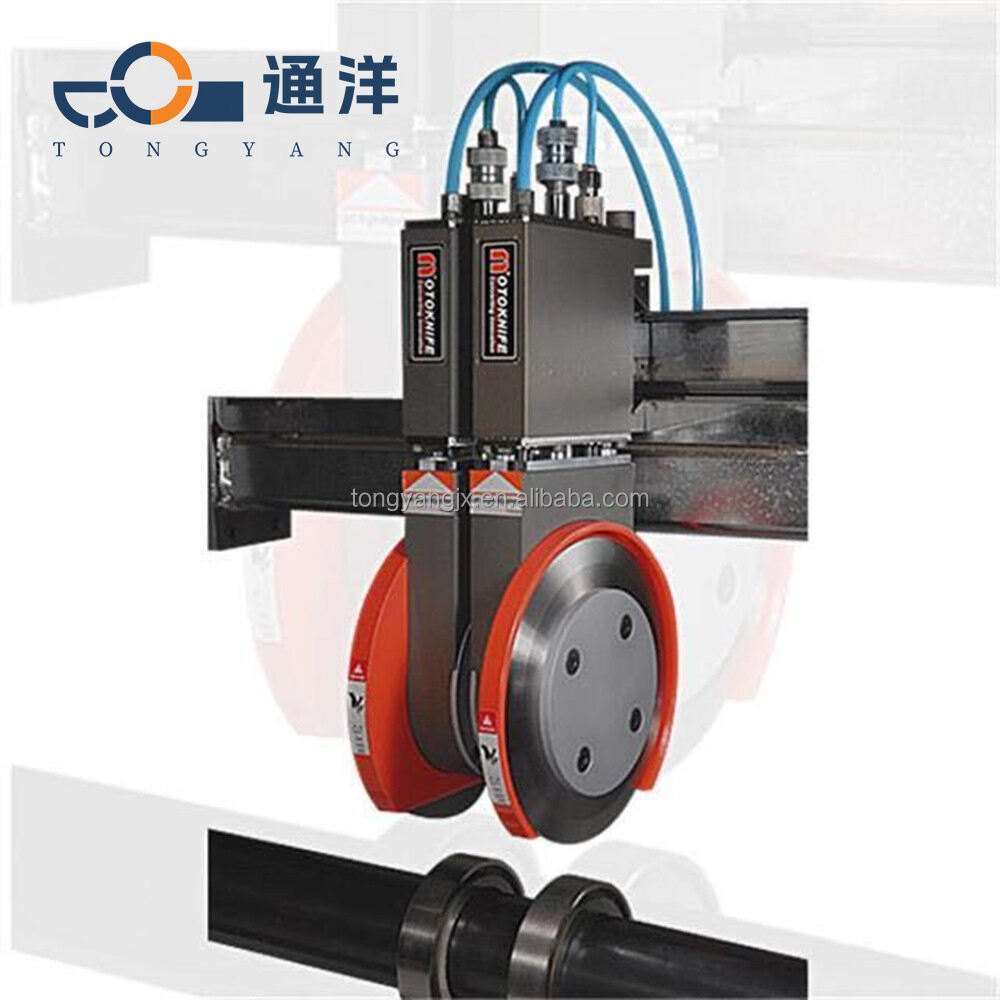

Easy to operate

The shape and structure of the semi-circular knife are relatively simple, making it easy for operators to master its usage method. It can be quickly installed and disassembled, which can reduce the time for equipment debugging and tool replacement, improve the utilization rate of the equipment, and thus enhance the overall processing efficiency.

Maintenance Process

Daily cleaning: After use, debris such as paper scraps, dust, and glue on the surface of the knife body should be removed in a timely manner. You can wipe it with a clean soft cloth. For some stubborn stains you can wipe them with a mild cleaner, but avoid the cleaner coming into contact with the blade to prevent the blade from rusting or being corroded.

Blade Maintenance:The blade is a crucial part of the cutting tool and needs to be kept sharp. Regularly check for wear and tear. In case of slight wear, it can be ground with professional tools, paying attention to the angle and force. If the wear is severe, replace the blade in a timely manner to ensure the cutting quality.

Regular Inspection: Conduct a comprehensive inspection of the corrugated paper knife regularly, including the sharpness of the blade, the structural integrity of the knife body, the flexibility of the movable parts, etc. If any problems are found, repairs or replacements should be carried out in a timely manner.

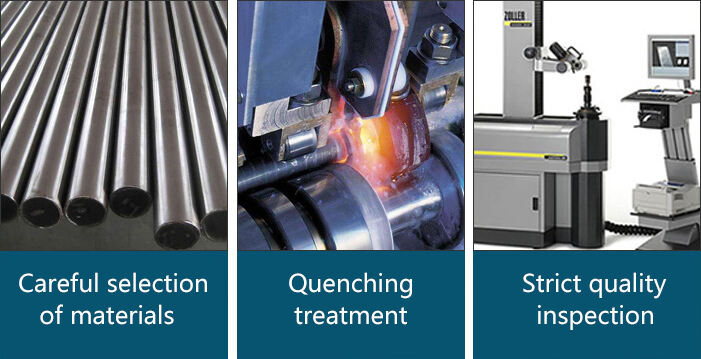

Our Advantages

Rich production experience: We have many years of production experience in the field of cutting tool manufacturing, and have accumulated a large amount of process data and production techniques. For the production of cutting tools of different types and specifications, we have mature process flows and solutions which can ensure the stability and consistency of product quality.

High-efficient production capacity: We possess large-scale production capacity and have multiple automated production lines, which can meet the order requirements of different quantities from customers.The advanced production management system ensures the efficient operation of the production process, shortens the production cycle of products, and enables us to deliver products to customers on time and in the required quantity.

Good after-sales service: We attach great importance to customer feedback and needs and provide a complete after-sales service system. Whether it is a technical problem during the product usage process or the needs for tool repair and replacement, our after-sales team can respond promptly and provide professional solutions, allowing customers to have no worries.

Reasonable price advantage: Through optimizing the production process, implementing large-scale production, and maintaining good cooperation with suppliers, we have effectively reduced the production cost. On the premise of ensuring product quality, we provide customers with competitive prices, help customers reduce procurement costs, and achieve a win-win situation.

Concept of environmentally friendly production: We pay attention to sustainable development strictly follow environmental protection requirements during the production process, and adopt environmentally friendly production processes and materials. We are committed to reducing the impact on the environment and achieving the unity of economic benefits and environmental benefits.