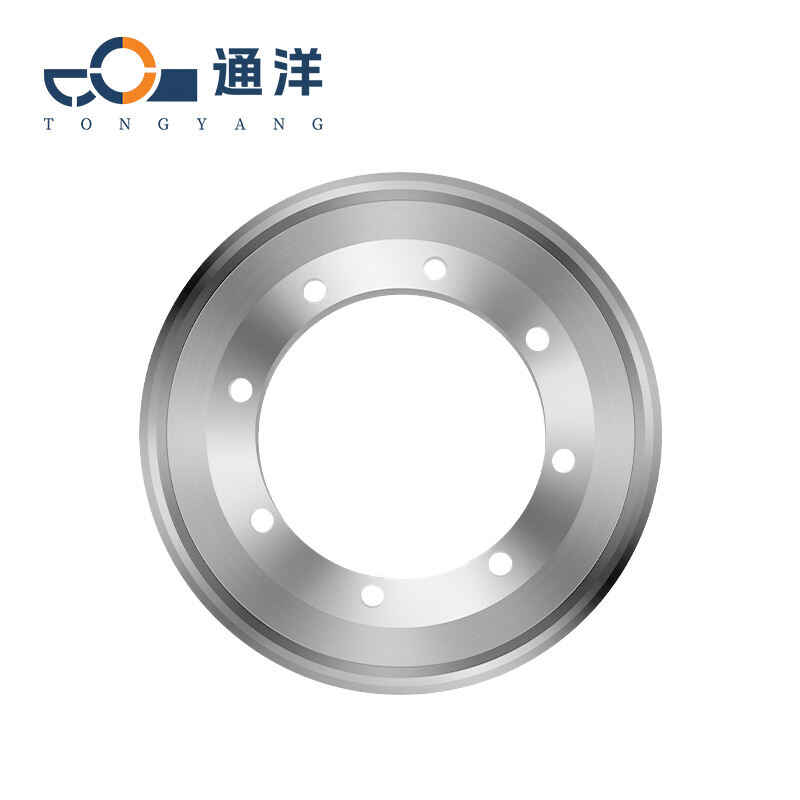

Cut cloth round blades

The handheld fabric cutting blade, with excellent processing technology and selected materials, can exhibit stable performance in cutting scenarios of flexible materials such as textile fabrics and leather. Its high-precision edge grinding process ensures neat and smooth cutting edges, while the selection of wear-resistant alloys, high-carbon steel and other materials effectively improves the impact resistance and service life of the blade. Even in the face of the need for cutting multiple layers of fabrics, it can achieve efficient operation through the dual advantages of materials and technology.

- Overview

- Recommended Products

Common materials and applications

SKS-7

Material characteristics:SKS-7 has high toughness and exhibits excellent cutting performance and stability when cutting leather or fabric. It also has a very high level of corrosion resistance, enabling it to maintain stability even in harsh working environments.

Application:With its excellent toughness and stable cutting performance, SKS-7 is commonly used for cutting leather, fabrics and paper. Whether it is dealing with the soft texture of leather or cutting multiple layers of fabrics and thin, translucent paper, its stable cutting performance can ensure that the cut edges are flat and smooth, greatly improving the processing efficiency and the quality of the finished products.

Stainless steel

Material characteristics:Stainless steel has high strength and hardness, enabling it to withstand greater external forces and be less likely to deform. When cutting leather raw materials, the cutting section is smooth, and it can continuously produce high-quality finished products.

Application:It can easily handle the cutting of leather of various thicknesses as well as the precise slitting of paper and cardboard, demonstrating powerful cutting performance. This tool can effortlessly complete the cutting of leather of different thicknesses. It also performs remarkably well in the field of paper and cardboard slitting, combining both cutting efficiency and quality.

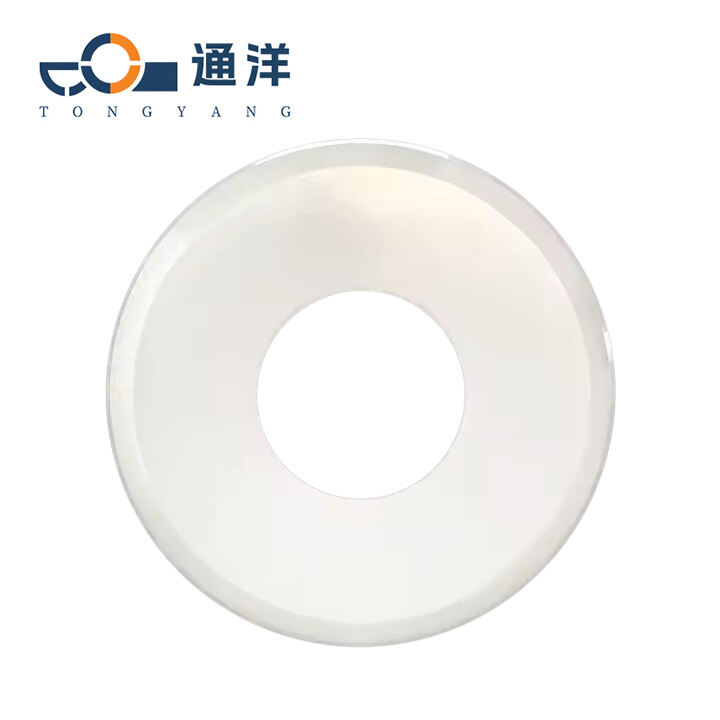

ceramics

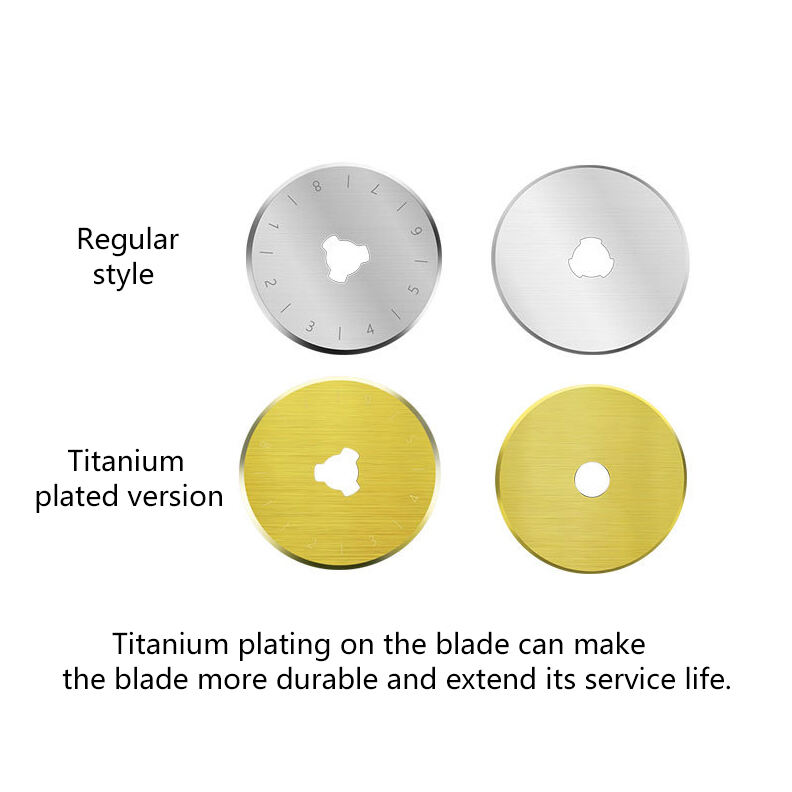

Material characteristics:It has extremely high hardness, which enables it to continuously maintain a sharp cutting edge during the cutting process. It can also preserve the cutting performance of the tool, reduce the frequency of tool replacement, and improve work efficiency.

Application:It can be used to cut leather of different thicknesses and achieve precise cutting. Thanks to the unique properties of the ceramic material, it will not scratch or scald the surface of the leather even when cutting leather rapidly, and it can keep the leather's original texture and performance.

Material customization

We also provide customization services for other materials

For each customized product, the material inspection will be carried out by a spectrometer.

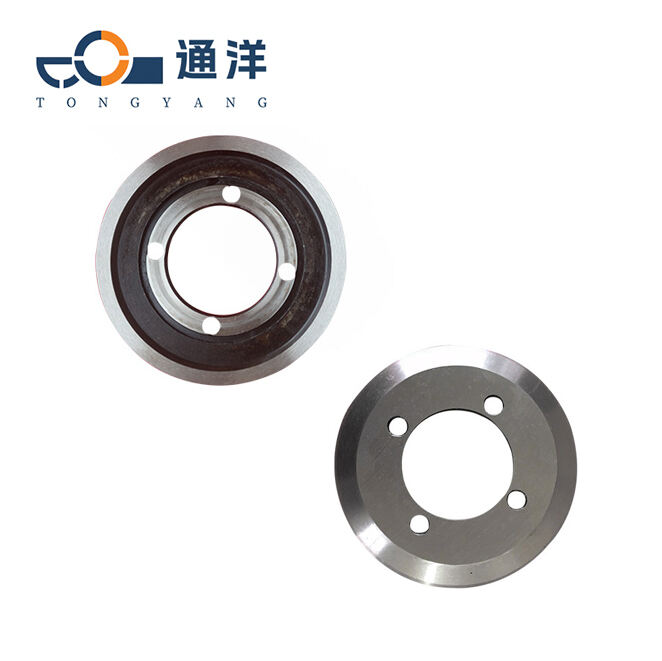

Common specifications

| Diameter | Inner diameter | Thickness | Application |

| 28mm | 5mm | 0.3mm | Smaller-sized toothed knives are usually used for cutting paper and thin fabrics. |

| 45mm | 8mm | 0.3mm | This one is larger in size and can be used to cut materials such as thin leather and cardboard. Moreover, its blade is not prone to chipping. |

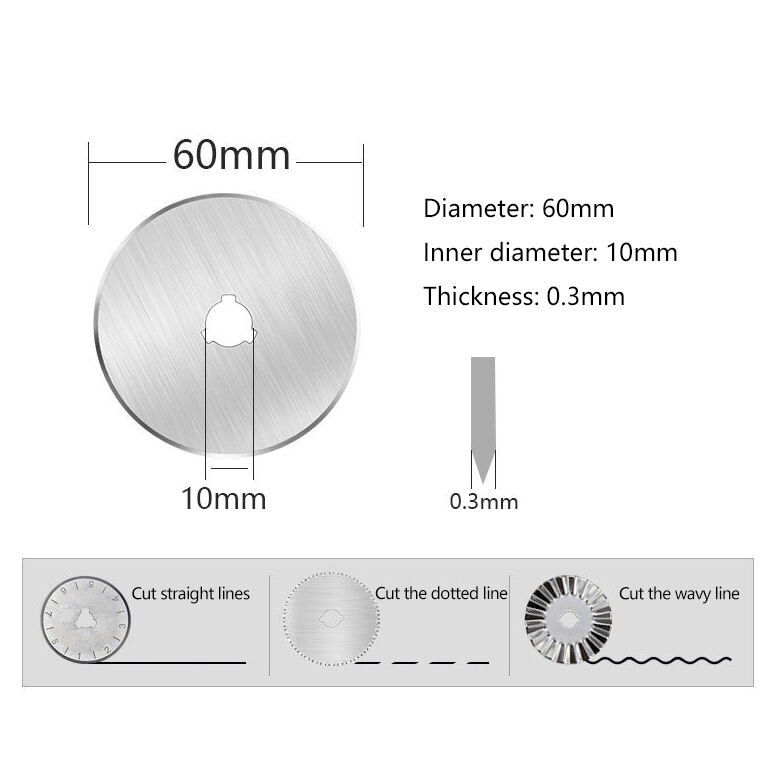

| 60mm | 10mm | 0.3mm | A larger tool diameter allows for cutting leather of different thicknesses, as well as silk, cotton fabric, chemical fiber, etc. It can ensure that the cutting edges are neat and smooth, without burrs or fraying phenomena, which helps to improve the quality of garment production. |

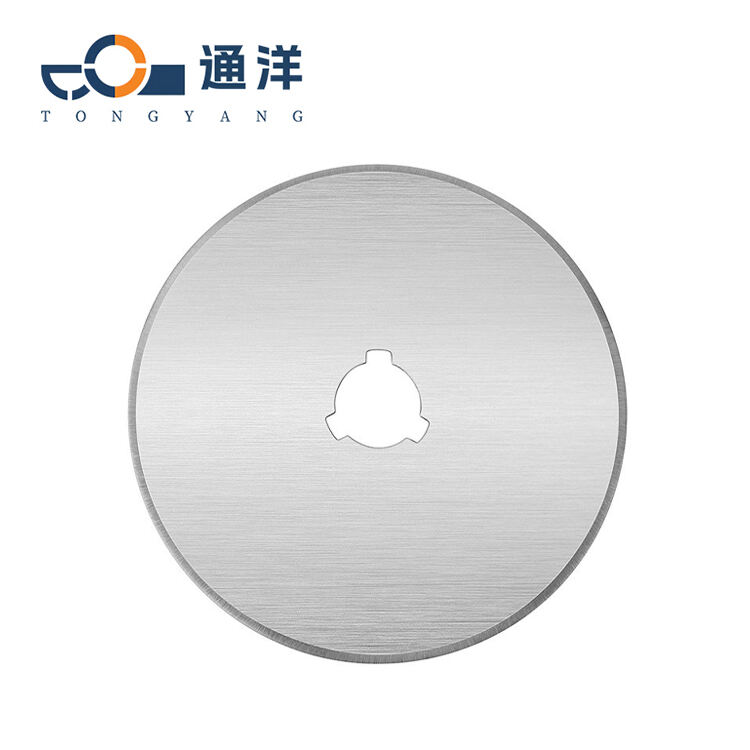

In addition, this tool is equipped with three different cutting edge designs, which can accurately adapt to the characteristics of various materials and meet diversified cutting needs. Whether it is a neat and straight edge,a flexible and undulating wavy edge, or a toothed edge with fine serrations, it can be easily handled, creating a variety of exquisite cutting styles with different styles for materials such as leather, silk, and cotton fabric.

Please measure the specifications that are suitable for the mechanical blade before customization(Parameters such as diameter, inner diameter, thickness, and punching)

Our advantages

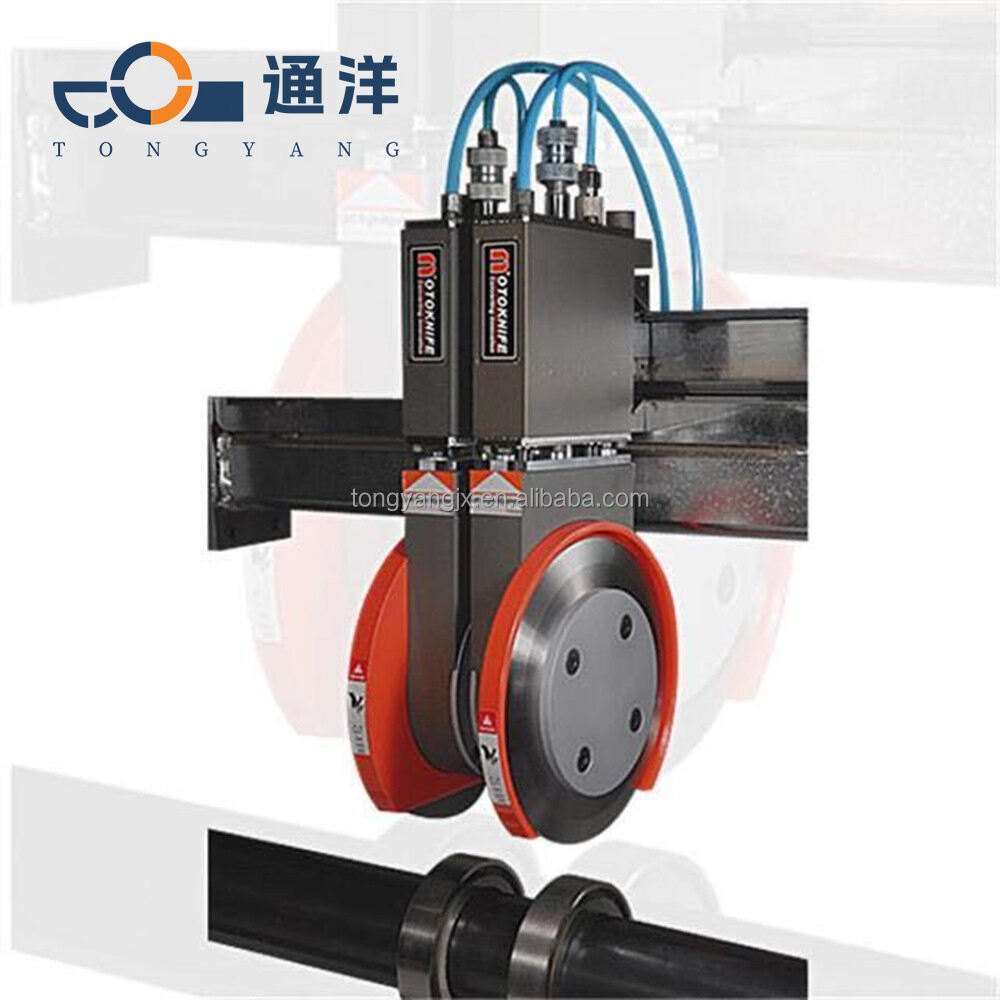

It has a rich and diverse range of application scenarios. Whether it is the precise shaping during leather cutting, the delicate cutting in fabric processing, the efficient operation in paper slitting, or the smooth handling of blanket cutting it performs excellently and can be regarded as the best choice for cutting operations in multiple fields. Each in-stock model will go through a strict on machine testing process. By simulating real cutting scenarios, a comprehensive inspection will be carried out on key indicators such as the sharpness, cutting precision, and stability of the blade to ensure that each blade can achieve excellent cutting results.

All products are required to undergo a strict notch detection process. From the raw materials to the finished products, the entire process is monitored. Multiple detection methods are employed to accurately identify potential defects, ensuring that the quality of each product reaches the highest standard.

Reliable Logistics Assurance: We ensure that your customized products are carefully packaged and safely transported to the designated location. Timely tracking and communication during the logistics process keep you informed of every step of the progress.