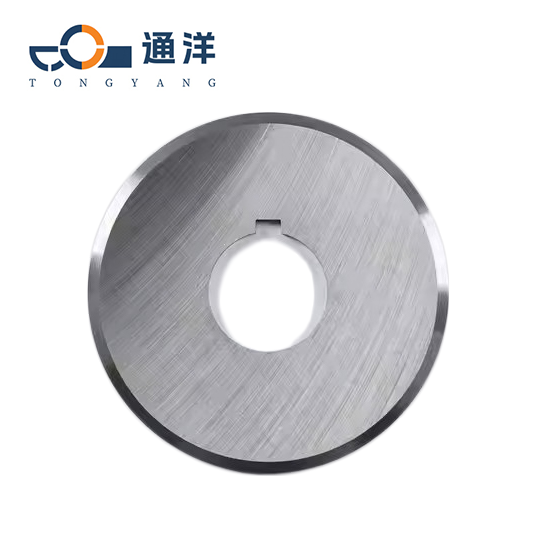

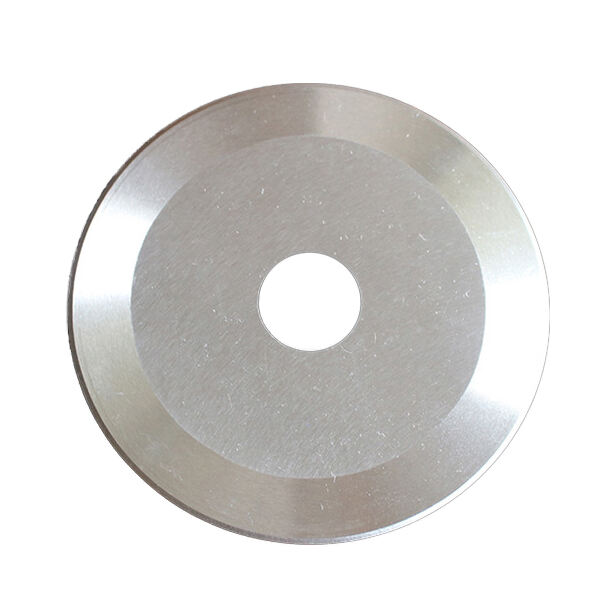

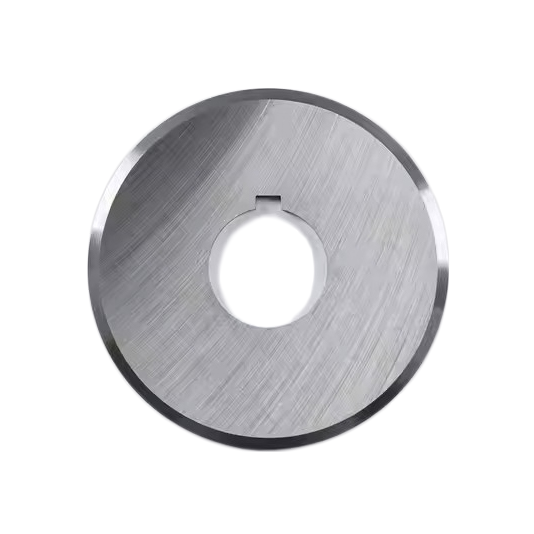

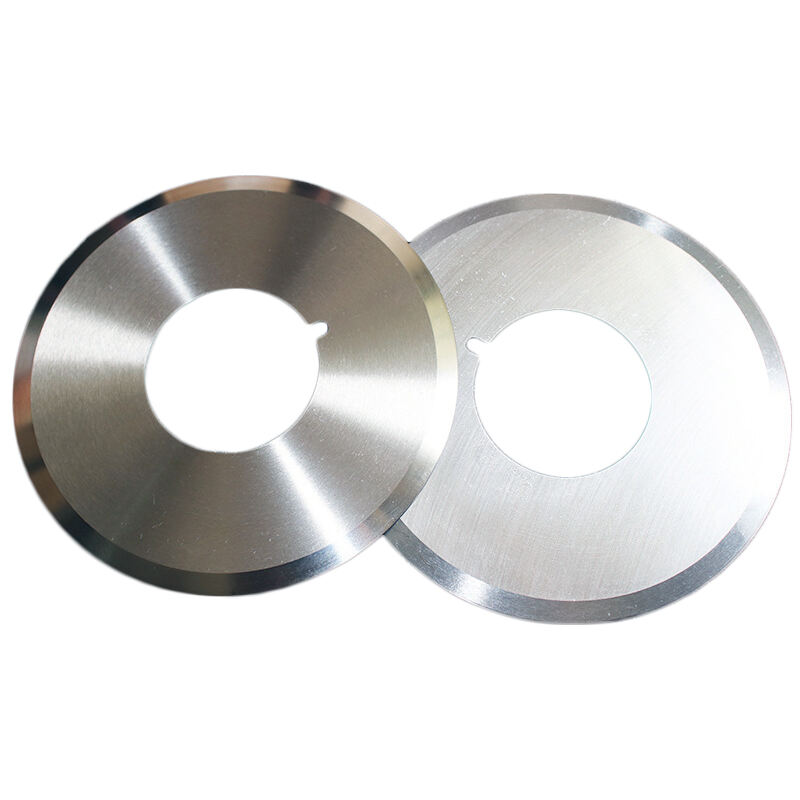

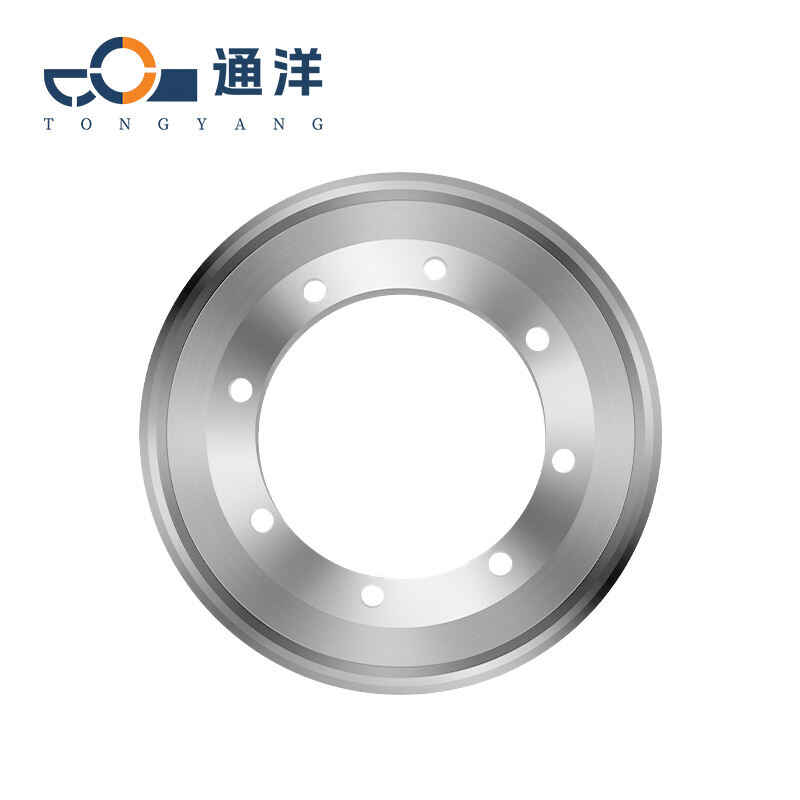

Film slitting knife

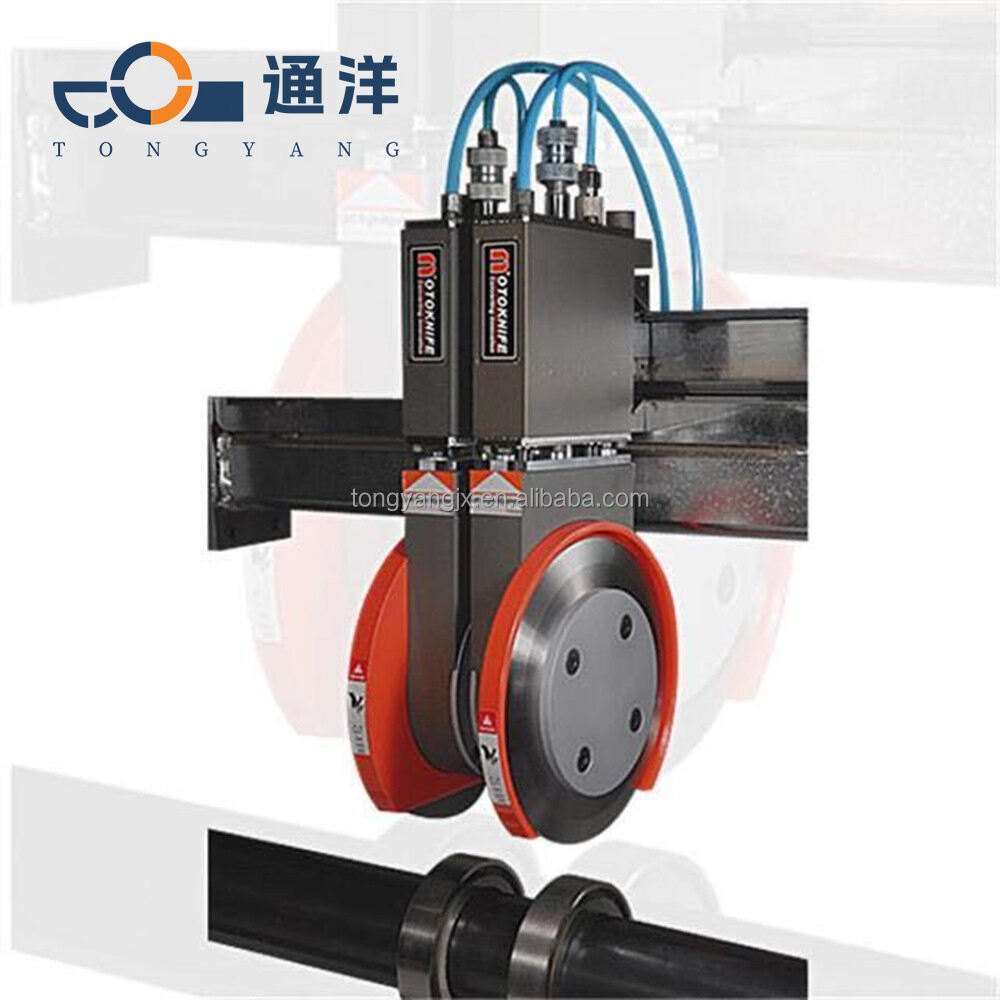

The cutting tools we produce are compatible with various types of slitting machines on the market. All of them have passed strict on-machine tests, ensuring stable and efficient operation. Whether it is the slitting of materials such as adhesive tapes, non-woven fabrics, rubber products, or toilet paper rolls, precise and smooth cutting can be achieved, providing a reliable guarantee for your production and processing.

- Overview

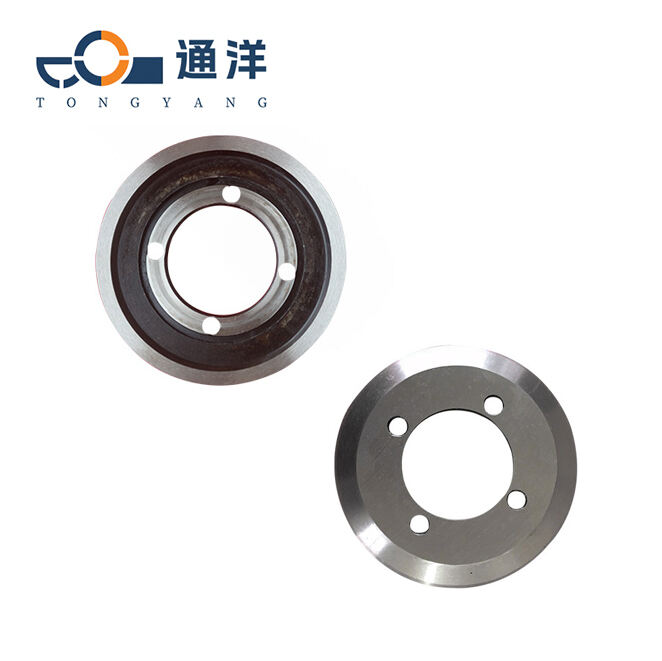

- Recommended Products

Common materials and applications

High-speed steel

Material characteristics:It has good toughness and cutting performance, and is not prone to chipping during cutting. At the same time, it has good wear resistance and hardness, and can maintain a certain degree of sharpness and service life.

Application:It is suitable for cutting ordinary plastic films, paper films, etc. with a thickness ranging from 0.01 to 0.5mm, such as the slitting of common packaging films and agricultural films. It is applicable to some materials that do not have extremely high requirements for cutting precision but have certain requirements for the toughness and economy of the cutting tools.

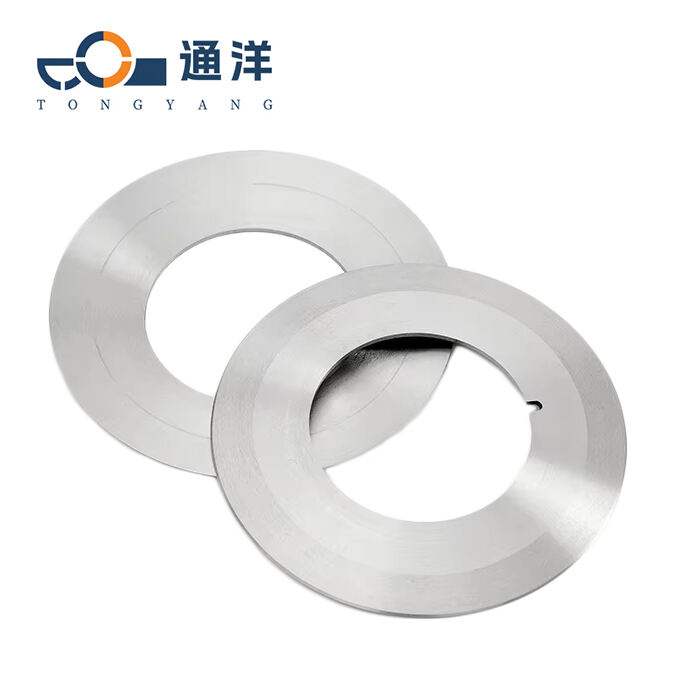

Cemented carbide

Material characteristics:Its hardness and wear resistance are much higher than those of high-speed steel. It can still maintain good cutting performance at high temperatures and enables high-speed cutting. With strong rigidity, it can ensure the stability of the cutting tool during the cutting process, thus improving the cutting precision.

Application:It is commonly used for cutting medium to high hardness film materials with a thickness ranging from 0.05 to 2mm, such as polyethylene terephthalate film (PET), polypropylene film (PP), polycarbonate film (PC), etc. In the electronics and electrical appliance industries, it is used for cutting lithium battery capacitor films, insulating films, etc. In the packaging industry, it is used for cutting some plastic film coils that require high-precision slitting.

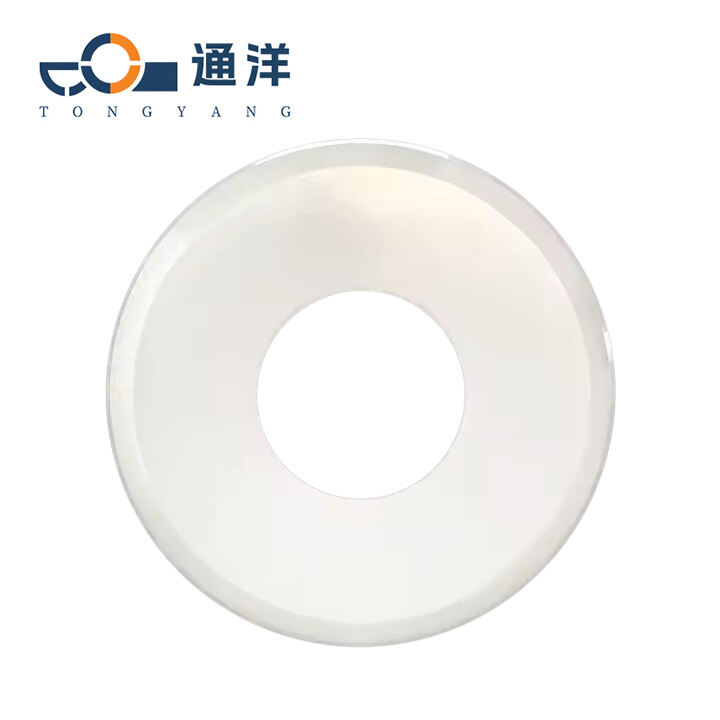

Ceramics

Material characteristics:It has high hardness, high wear resistance, good heat resistance and chemical stability.The cutting edge of the tool is sharp, which can maintain good cutting accuracy. Moreover, it is not easy to have a chemical reaction with the film material, and will not cause pollution to the film.

Application:It is mostly used for the cutting of films with high requirements for hygiene conditions and cutting quality, such as the cutting of food packaging films and pharmaceutical packaging films. It is also widely applied in the scenarios of film cutting in dust-free workshops with strict requirements for environmental cleanliness.

Material customization

We also provide customization services for other materials

For each customized product, the material inspection will be carried out by a spectrometer.

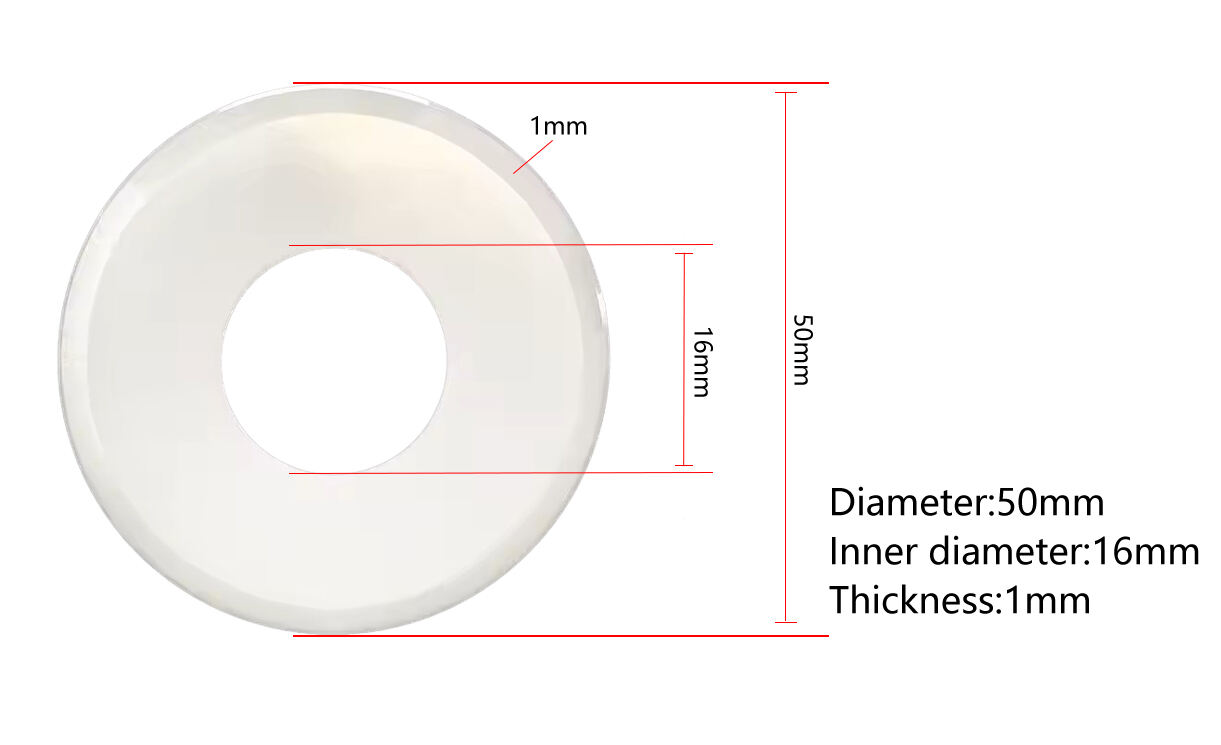

Common specifications

| Diameter | Inner diameter | Thickness | Application |

| 18mm | 5mm | 0.3mm | It is commonly used under the cutting conditions with high precision and in narrow spaces. |

| 28mm | 5mm | 0.3mm | It is commonly used for the slitting of relatively thin video packaging films. |

| 45mm | 8mm | 0.3mm | For foods that require packaging films to be slit into small-sized packaging bags, such as candies, chewing gums, etc., this blade can cut the packaging films into appropriate sizes. |

| 50mm | 16mm | 1mm | It is commonly used for the slitting of packaging films for food, medical consumables, etc. It can achieve precise slitting and play a good protective role. |

| 76mm | 25.4mm | 1.2mm | It is commonly used for cutting medium-hardness film materials such as PET, PP, PC, etc., with a thickness ranging from 0.05 to 1mm. |

| 100mm | 25.4mm | 2mm | It can slit thicker film rolls, and the cutting surface is smooth and flat. |

Please measure the specifications that are suitable for the mechanical blade before customization(Parameters such as diameter, inner diameter, thickness, and punching)

Our advantages

The cutting tools we produce are compatible with various types of slitting machines on the market. All of them have passed strict on-machine tests, ensuring stable and efficient operation. Whether it is the slitting of materials such as adhesive tapes, non-woven fabrics, rubber products, or toilet paper rolls, precise and smooth cutting can be achieved, providing a reliable guarantee for your production and processing.