مکانیک بریدن با تیغ گرد

فیزیک زیربنای کارایی بریدن دایرهای

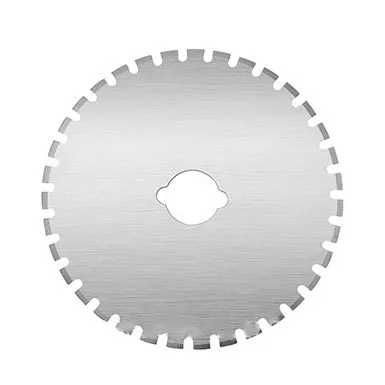

تیغهای گرد ابزارهای برجستهای هستند به خاطر کاربرد منحصر به فرد حرکت دایرهای آنها در بریدن مواد. کلید کارایی آنها در فیزیک بنیادی حاکم بر بریدن دایرهای قرار دارد. وقتی یک تیغ گرد دور میچرخد، نیروهای جداسازی را تولید میکند که به طور کارآمد مواد را در سطح میکروسکوپی جداسازی میکنند، بدون نیاز به فشار قابل توجهی به سمت پایین. این پدیده به بریدن هموارتر کمک میکند و احتمال آسیب دیدن ماده بریده شده را کاهش میدهد.

نیروهای درگیر در فرآیند برش، از نیروی گریز از مرکز استفاده میکنند که به جداسازی مواد کمک میکند. نیروی برشی در طول لبه به عنوان نوک تیغه میچرخد، دقت هر برش را افزایش میدهد.

قطر تیغ نقش مهمی در تعیین سرعت و کارایی برش ایفا میکند. تیغهای بزرگتر معمولاً منطقه بیشتری را پوشش میدهند، که ممکن است سرعت برش را افزایش دهند و تعداد عبورها را برای تکمیل وظیفه کاهش دهد.

دادههای عددی نشان میدهد که تیغهای دایرهای میتوانند سرعت برش تا ۲۵٪ بیشتر از ابزارهای یال مستقیم داشته باشند، بیشتر به خاطر توانایی آنها در حفظ حرکت برش پیوسته بدون قطع.

به طور خلاصه، حرکت دایرهای انتقال انرژی دینامیکی ایجاد میکند که منجر به سرعت برش بالاتر میشود، که تیغهای گرد را برای بسیاری از کاربردهای صنعتی ترجیحی میکند.

دینامیک چرخشی و تعامل با ماده

بررسی اصول دینامیک چرخشی نور روشن میکند که چرا تیغهای گرد در وظایف برش برتری دارند. جنبههای زاویهای نقش محوری در عملکرد تیغ بازی میکند، که اطمینان میدهد انرژی وارد به تیغ به طور موثری در فرآیند برش استفاده شود. هنگامی که تیغ چرخیده، با ماده تعامل میکند - جایی که سرعت و سختی ماده به صورت مستقیم بر کیفیت و کارایی برش تأثیر میگذارد.

سرعت چرخش تیغ باید بهینه باشد، با توجه به سختی مادهای که قطع میشود. چرخشهای سریعتر میتوانند کارایی برش را بهبود بخشد، اما ممکن است منجر به خستگی بیشتر تیغ شوند.

تحقیقات نشان میدهد که حفظ تنظیمات RPM مناسب میتواند تنش روی تیغ را به طور قابل ملاحظهای کاهش دهد، که منجر به طول عمر بیشتر و عملکرد برش ثابتتر میشود.

برخلاف ابزارهای معمولی با لبه مستقیم، تیغهای گرد تعامل پیوسته لبه برش را فراهم میکنند که وقفهها را کاهش میدهد و برشهای صافتری ارائه میدهد.

ترکیب دینامیک چرخشی و تعامل ماده، گزینه ای برتر برای مختلف کاربردهای برشی ایجاد می کند، کارایی را فراهم می آورد و هزینه های عملیاتی را با گذر زمان کاهش می دهد.

نوآوری های مواد در طراحی تیغ گرد

فلزهای آلیاژی پیشرفته برای بهبود استحکام

پیشرفت های اخیر در علوم مواد نقش مهمی در توسعه آلیاژهای با عملکرد بالا برای تولید تیغ ایفا کرده است، که به طور قابل ملاحظه ای استحکام تیغ های گرد را افزایش داده است. این آلیاژها از ترکیب شیمیایی دقیقی تشکیل شده اند که بیشینه سازی نیرو و مقاومت را تضمین می کنند و اطمینان می رسانند که تحت عملیات برش سنگین به طور سریع تخریب نشوند. به عنوان مثال، استفاده از عناصری مانند کروم و وانادیوم سختی و مقاومت آنها را در برابر خوردگی افزایش می دهد و به طول عمر بلندتری کمک می کند.

تحقیقات نشان داده است که تیغ هایی که از آلیاژهای پیشرفته ساخته شده اند، عمر کاربردی تا ۴۰٪ بیشتری نسبت به مواد سنتی دارند، که این امکان را به صنایع می دهد تا هزینه های مرتبط با جایگزینی مکرر را کاهش دهند.

پوششهایی برای کاهش اصطکاک و سوختگی

فناوری پوششدهی به روشهای طراحی مهندسی تغییرات چشمگیری ایجاد کرده است تیغهای گرد با کاهش قابل توجه اصطکاک و سوختگی، نقش مهندسی سطح در طراحی چاقو بسیار حیاتی شده است. انواع پوششها، مانند نیترید تیتانیوم و سرامیک، به منظور بهبود عملکرد چاقو به کار میروند تا لایه محافظ صلبی ایجاد کنند که اصطکاک را در فرآیندهای برش کاهش دهد. این نوآوریها باعث طولانیتر شدن عمر چاقو میشوند به دلیل کاهش زیاد در تخریب سطحی.

دادههای مقایسهای نشان میدهد که چاقوهای پوشیده شده در محیطهای سخت، نرخ سوختگی بسیار کمتری نسبت به چاقوهای بدون پوشش دارند.

صنعت این پوششها را به طور گسترده پذیرفته است و بازخورد مثبتی در مورد بهبود عملکرد برش و کاهش نیاز به نگهداری دریافت شده است.

مهندسی دقت در فناوری چاقوی گرد

لبههای برشی لیزری برای دقت میکروسکوپی

دقت در فناوری برش با ورود به کار یالهای برش لیزری برای تیغهای دایرهای، به شکل قابل توجهی افزایش یافته است و دقت میکروسکوپی را ارائه میدهد. این فناوری سharpenس و همواری یالهای تیغ را افزایش میدهد و منجر به برشهای تمیزتر و دقیقتر میشود. صنایعی مانند پارچه، خودرو و فلزات بهبود قابل توجهی در کیفیت کار دیدهاند، زیرا تیغهای برش لیزری ضایعات مواد را کاهش میدهد و کارایی عملیاتی کلی را بالا میبرد.

یک مطالعه توسط موسسه فناوری تولید نشان میدهد که استفاده از یالهای برش لیزری منجر به کاهش ۱۵٪ در عیوب مواد شده است.

تعادل بین ضخامت تیغ و انعطافپذیری

در طراحی تیغ دایرهای، یافتن تعادل بهینه بین ضخامت تیغ و انعطافپذیری برای عملکرد ضروری است. ضخامت تیغ توانایی آن را برای برش از طریق مواد مختلف تحت تأثیر قرار میدهد، در حالی که انعطافپذیری منورablity را افزایش میدهد. مهندسان استراتژیهای طراحی نوآورانهای را برای دستیابی به این تعادل به کار میبرند، تا نیازهای خاص صنایع و وظایف برش را برآورده کنند.

به عنوان مثال، در مواد نرم مثل کاغذ، تیغهای نازکتر مناسبتر هستند، در حالی که برای مواد سخت مثل فلزات، تیغهای ضخیمتر و سختتر الزامی است.

دادههای پشتیبان نشان میدهد که تعادل مناسب طول عمر برش و دقت آن را تا ۲۰٪ افزایش میدهد.

کاربردهای صنعتی برش با تیغ گرد

پردازش غذا: برشهای تمیز و بهداشت

تیغهای گرد نقش کلیدی در پردازش غذا ایفا میکنند، جایی که حفظ سطوح برش تمیز اهمیت بالایی در تضمین بهداشت و ایمنی دارد. در این صنعت، تیغها باید معیارهای شدیدی را برآورده کنند تا آلودگی را جلوگیری کنند و با مقررات مربوط به ایمنی غذا هماهنگ باشند.

برای مثال، USDA و FDA راهنماییهای خاصی در مورد ماده، تمیزبودن و نگهداری ابزارهای برشی استفادهشده در تولید غذا دارند.

تولید: ساخت فلزی با سرعت بالا

در بخش تولید، استفاده از گیره دایرهای برای برش به صورت معمولی در فرآیندهای سریع تولید فلزات جاگیر شده است، زیرا قادر است برشهای سریع را بدون کاهش دقت ارائه دهد. پیشرفتها در فناوری گیره، مانند افزایش ثبات و محکمیت لبه و طول عمر بالاتر، منجر به فرآیندهای تولیدی کارآمدتر شده است که نیازهای بالاً تولید مدرن را پوشش میدهد.

تحقیقات نشان داده است که شرکتهایی که سیستمهای برش با گیره دایرهای را پیادهسازی کردهاند، بهبود قابل توجهی در بهرهوری خود مشاهده کردهاند—برخی گزارش دادهاند که سرعت پردازش تا ۳۰٪ افزایش یافته است در حالی که دقت حفظ شده است.

پایداری در تولید گیره دایرهای

مواد قابل بازیافت و فرآیندهای دوستانه با محیط زیست

پایداری در تولید تیغ گرد از استفاده از مواد قابل بازیافت و فرآیندهای دوستدار محیط زیست آغاز میشود. سازندگان فلزات بازیابیشده را در تیغها به کار میبرند، که با اهداف پایداری جهانی هماهنگ است و کمک میکند تا زبالههای صنعتی کاهش یابد. این تغییر نشاندهنده یک روند گستردهتر در صنعت برای کاهش تأثیرات زیستمحیطی و ترویج استفاده مجدد از مواد است.

دادههای از اتحادیه جهانی پلاستیک (2023) نشان میدهد که استفاده از مواد قابل بازیافت میتواند مصرف انرژی را به میزان 15٪ کاهش دهد، که امکان صرفهجویی در منابع را نشان میدهد.

استراتژیهای طول عمر برای کاهش زباله

برای مقابله با کاهش زباله، سازندگان بر روی استراتژیهایی تمرکز میکنند که طول عمر تیغ را افزایش میدهد. تیغهای طولانیمدت به پایداری کمک میکنند زیرا نیاز به جایگزینی کمتری دارند و بنابراین زباله را کاهش میدهند.

این طول عمر با استفاده از مواد پیشرفته و تکنیکهای پوشش، که به تحمل بیشتر و کارایی برش بالاتر کمک میکنند، دستیاب شده است. برای نمونه، مطالعهای توسط مجله علم ساخت (سال 2023) نشان داد که چاقوهاي کربید تونگستن 35 درصد طولانیتر از گزینههای معمولی مقاومت میکنند، که این موضوع به طور قابل توجهی زباله را کاهش میدهد.

چالشها در سیستمهای مدرن چاقوی دایرهای

مدیریت گرما در استفاده حجمی بالا

جمع شدن گرما در سیستمهای چاقوی دایرهای در مواقع کاربردهای برش حجمی بالا، یک چالش قابل توجه را ایجاد میکند. این گرما فراوان میتواند منجر به خمش چاقو، کاهش کارایی برش و آسیب به مواد پردازشی شود.

برای مقابله با این مشکلات، تولیدکنندگان سیستمها و تکنیکهای سردکننده را توسعه دادهاند که از مواد خاصی برای دفع گرما استفاده میکنند. به عنوان مثال، سیستمهای سردکننده پیشرفته طراحی شدهاند تا دمای مناسب چاقو را حفظ کنند و اطمینان حاصل شود که عملکرد کاهش نیافتد.

معادله هزینه نسبت به عملکرد

سازمانها در زمانی که تصمیم میگیرند بین هزینه و عملکرد در سرمایهگذاریهای فناوری برش تیغ گرد انتخاب کنند، با تصمیمگیری پیچیدهای روبرو هستند. این انتخاب اغلب به عواملی مانند مواد تیغ، پیچیدگی طراحی و استفاده از فناوری جدید بستگی دارد که همه آنها بر روی کارآمدی اقتصادی تأثیر میگذارند.

نظرات خبرگان نشان میدهد که هرچند صرفهجویی در هزینه حائز اهمیت است، اما نباید معیارهای عملکرد بالا راompromised کرد.

درک این تجارتoffs به سازمانها اجازه میدهد انتخابهایی اطلاعاتی که میزان اقتصادی را با نیاز به عملکرد بهینه تیغ در محیطهای برش حجمزیاد متوازن کند.

سوالات متداول برش تیغ گرد

چه چیزی باعث میشود تیغهای گرد از ابزارهای لبهی مستقیم کارآمدتر باشند؟

تیغههای گرد به دلیل حرکت دایرهای خود که از نیروی گریز از مرکز بهره میبرد، کارآمدتر هستند و این امکان را فراهم میکنند که برشها آسانتر انجام شوند و وقفهها به حداقل برسد.

چگونه قطر میله تأثیری بر کارایی برش دارد؟

قطر تیغههای بزرگتر میتواند سرعت برش را افزایش داده و تعداد گذرها را کاهش دهد، بنابراین کارایی را بهبود میبخشد.

چرا پوششها در طراحی تیغه گرد مهم هستند؟

پوششها اصطکاک و خرج کار را کاهش میدهند، که منجر به طول عمر بیشتر تیغه و بهبود عملکرد برش میشود.

چالشهای مدیریت گرما در استفاده حجم زیاد چیست؟

مدیریت گرما اهمیت دارد زیرا گرما فراوان میتواند تیغهها را تحریف کند و کارایی برش را کاهش دهد. سیستمهای سازگارسازی و موادی با رسانایی گرمایی بالا برای دفع گرما به کار میروند.

چگونه مواد قابل بازیافت در پایداری تولید تیغه نقش دارند؟

مواد قابل بازیافت زباله صنعتی و مصرف انرژی را کاهش میدهند و تولید را با اهداف پایداری جهانی هماهنگ میکند.