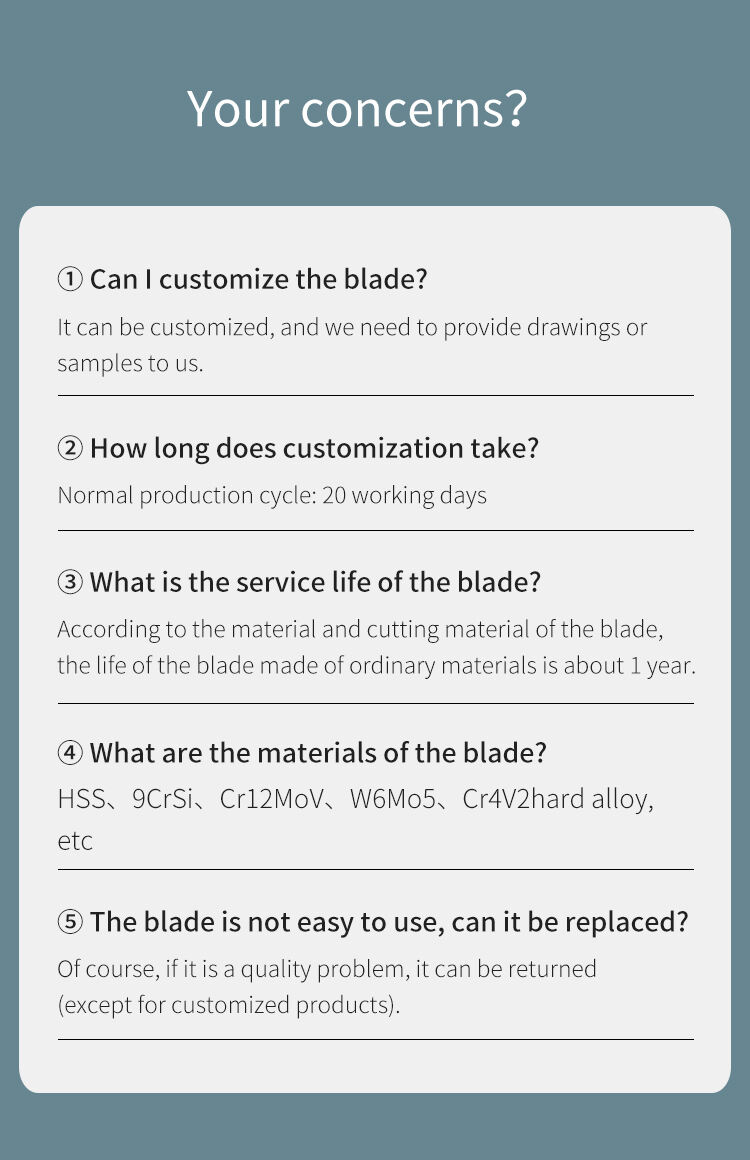

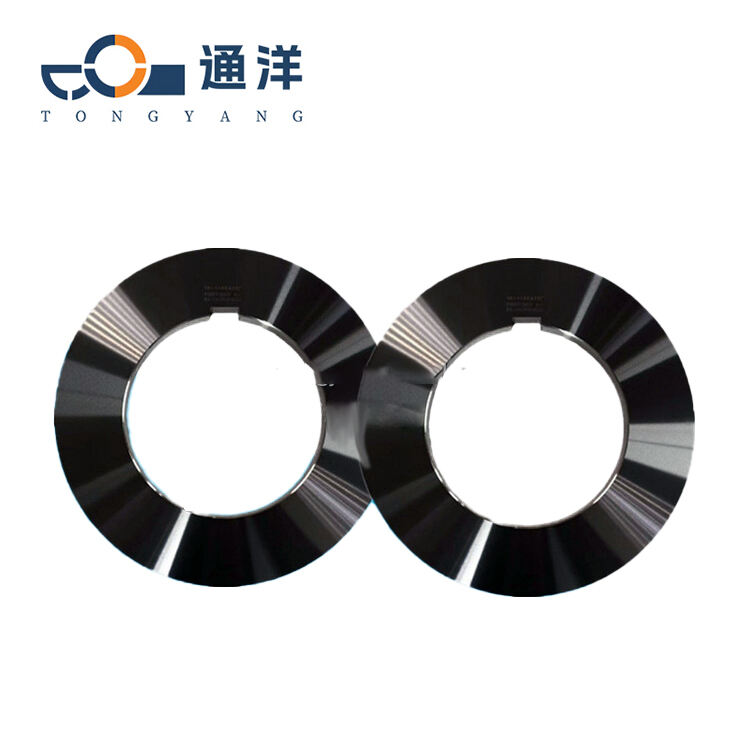

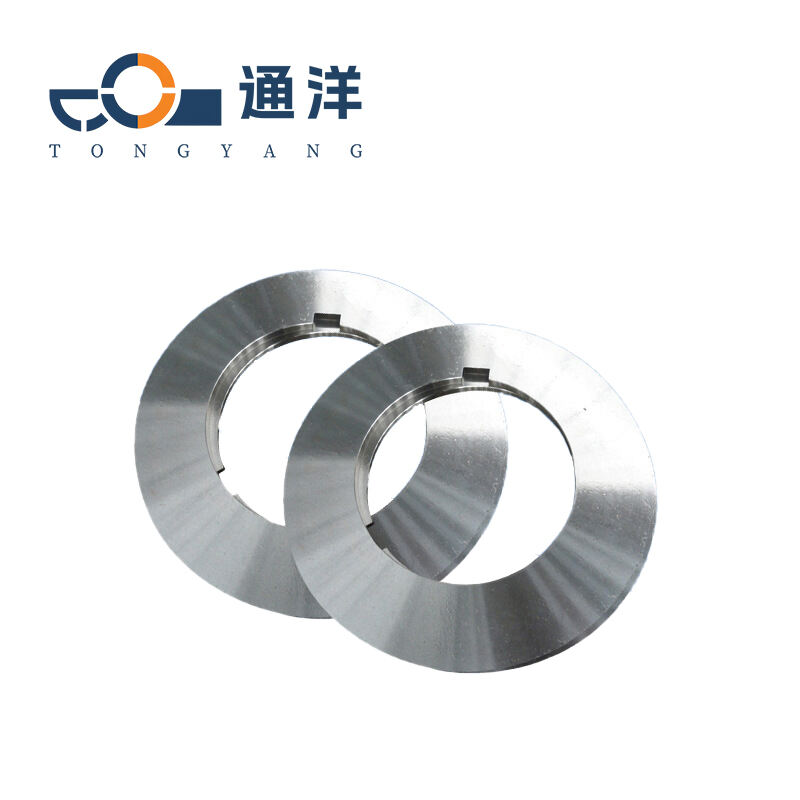

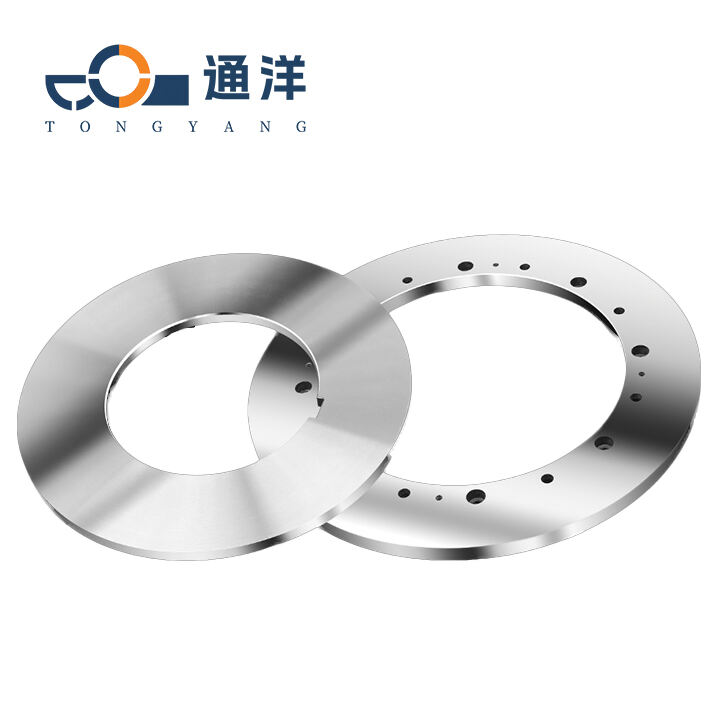

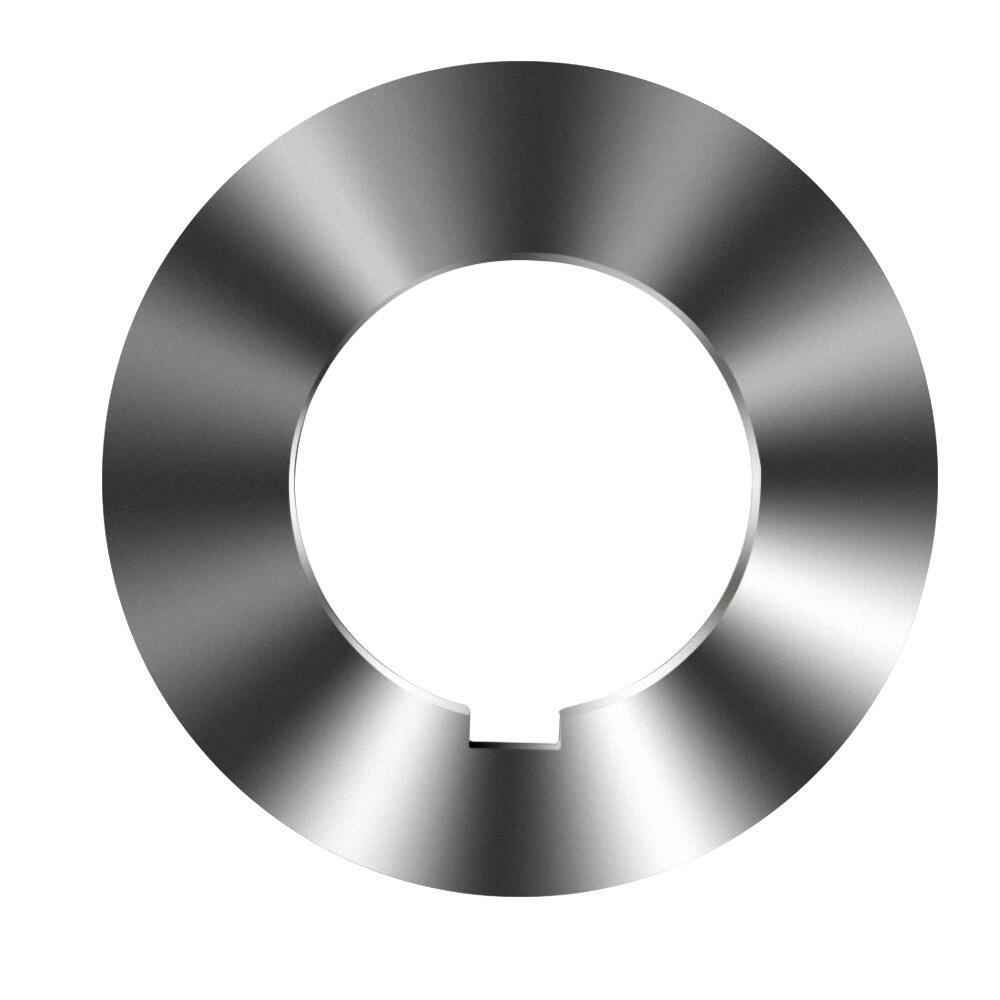

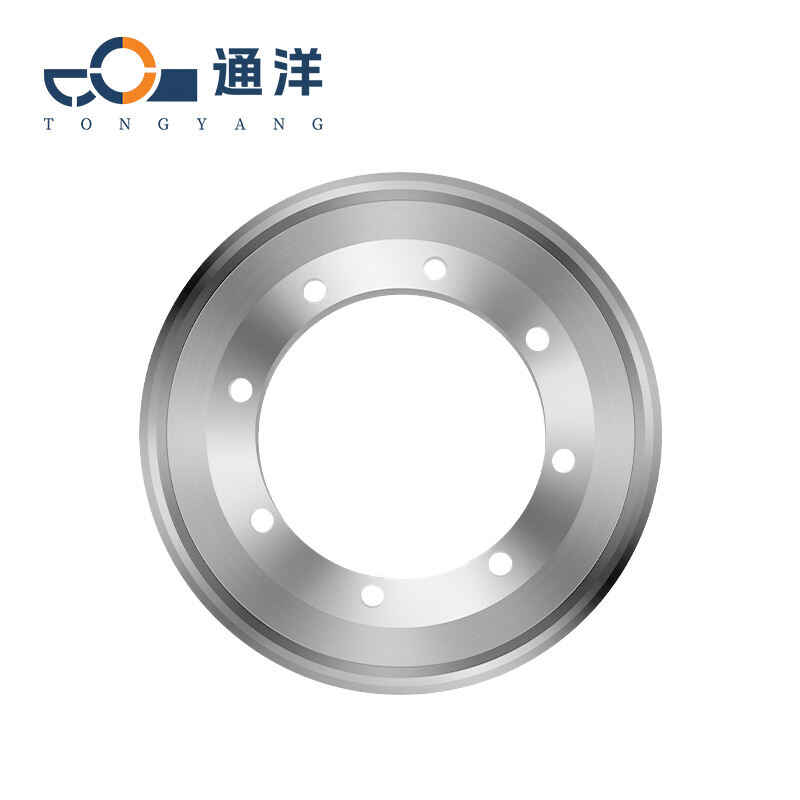

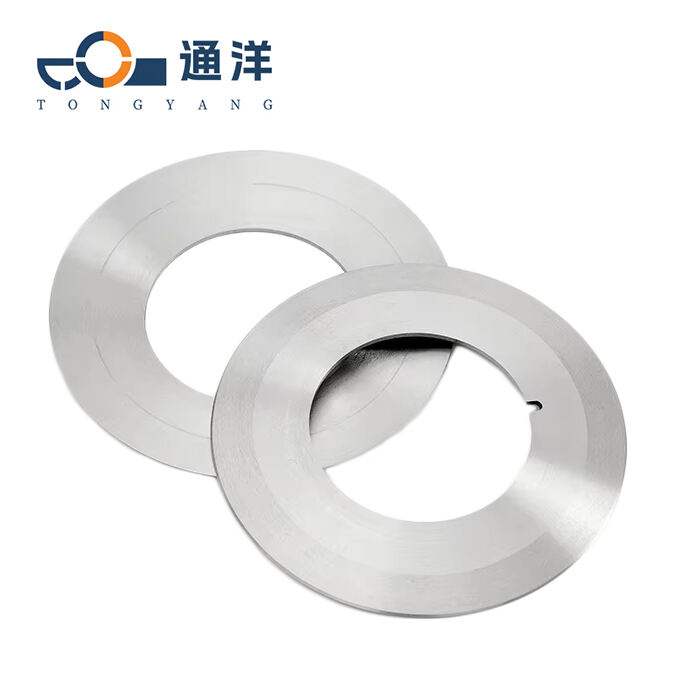

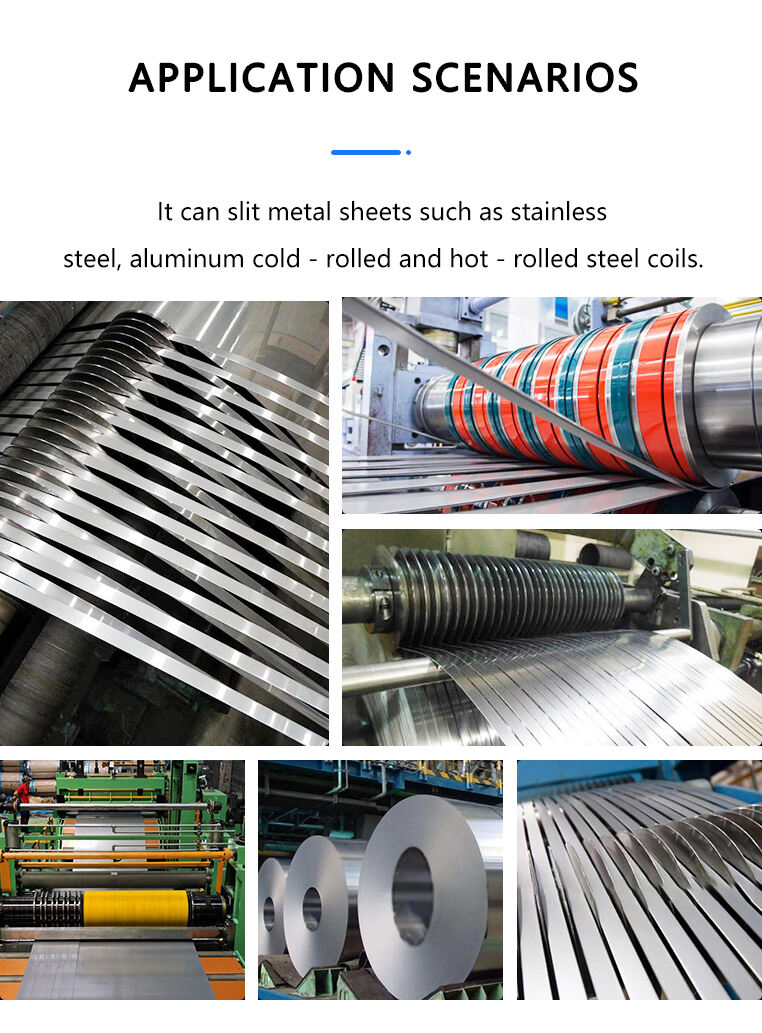

Blades of metal slitting machines

It is suitable for the slitting of medium and thin hot-rolled steel plates with a thickness of 1.5 - 3mm for subsequent parts that need to be bent or welded

- Overview

- Recommended Products

Common materials and applications

High-speed steel

Material characteristics:It has a fast cutting speed and good edge retention. It is not prone to chipping and can maintain excellent cutting performance even when working for a long time.

Application:It is used to slit metal sheets with general hardness, such as thin and medium plates of common carbon steel and stainless steel. In industries like automobile manufacturing and home appliance production, it is applied to longitudinally shear metal sheets with a thickness of about 0.5 - 3mm, which can meet the requirements of high shearing precision and quality.

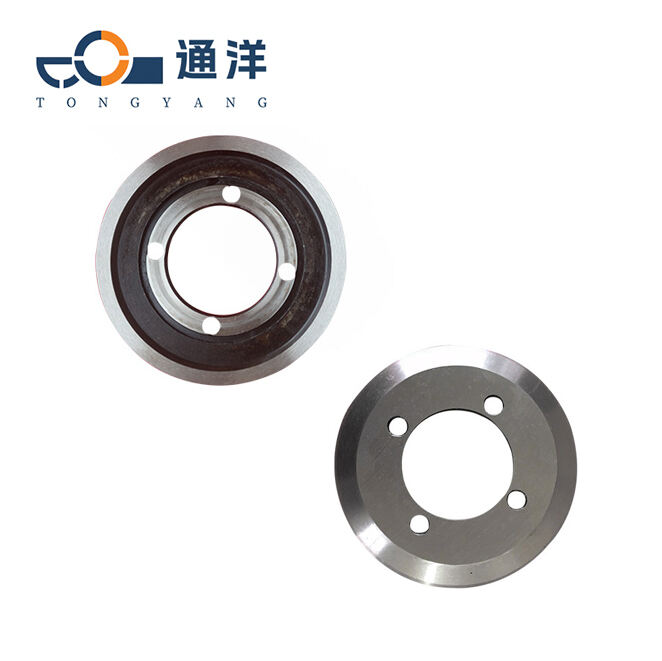

SKD-11

Material characteristics:It has extremely high hardness, wear resistance and compressive strength and it is structure is uniform. The cutting surface of the metal coils slit by it is flat and even, meeting the high quality requirements.

Application:It is commonly used for slitting copper, stainless steel, alloy steel, etc. In industries such as electronics and aerospace, which have extremely high requirements for material precision and surface quality it is used for slitting thin stainless steel sheets or thin high-strength alloy steel sheets with a thickness of 0.1 - 2mm. It can ensure the flatness and perpendicularity of the slitting edges and meet the processing requirements of high precision.

H13

Material characteristics:The thermal fatigue and wear resistance properties of the material with H13 grade enable it to maintain strength and hardness during high-intensity production.

Application:It is commonly used for slitting metal materials with large thickness and high strength such as hot-rolled steel coils. When longitudinally shearing steel coils with a thickness of 3 to 10 mm it has good cutting ability and durability.

Material customization

We also provide customization services for other materials.

For each customized product, the material inspection will be carried out by a spectrometer.

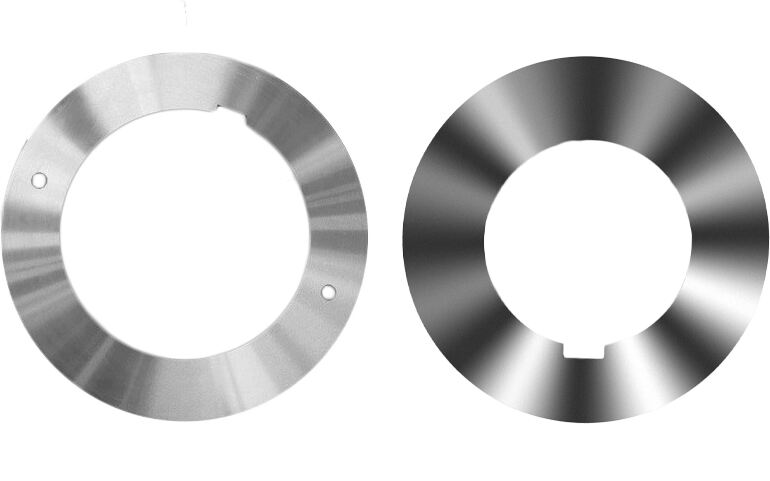

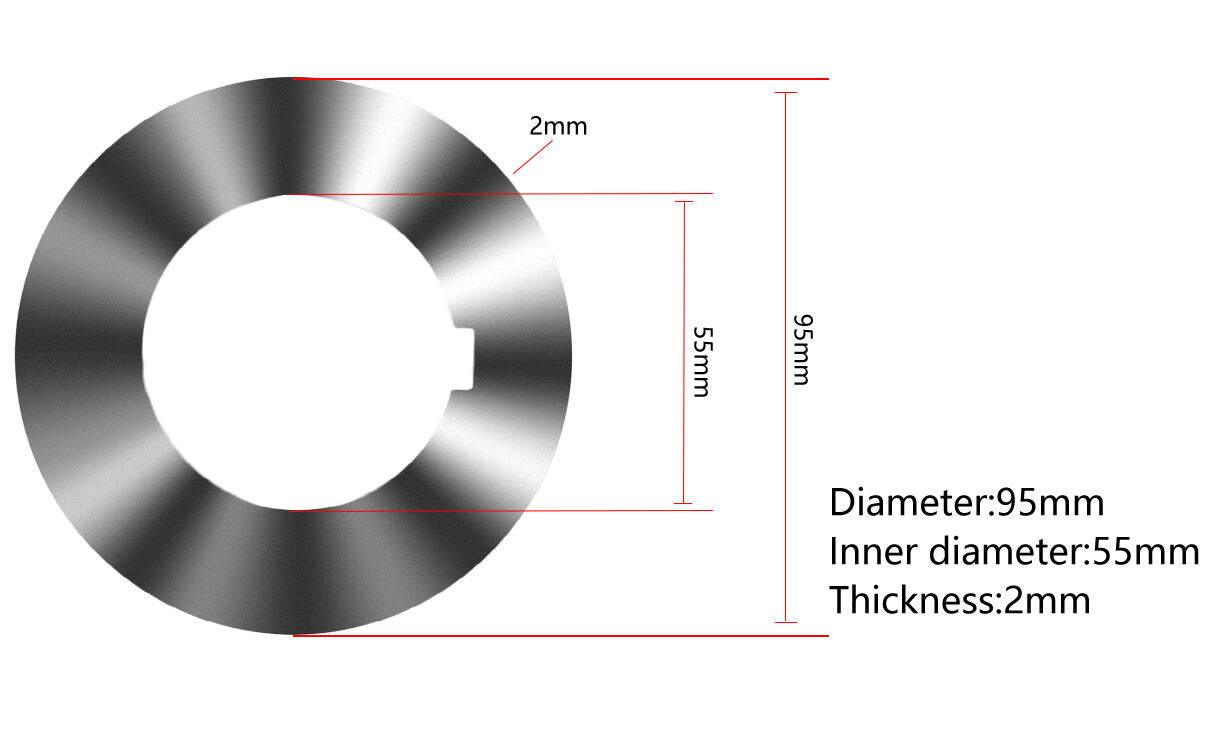

Common specifications

| Diameter | Inner diameter | Thickness | Application |

| 95mm | 55mm | 2mm | Suitable for slitting thin - gauge copper foils and aluminum foils in the electronics industry, like the production of circuit boards, where high precision and smooth edges are required. |

| 105mm | 32mm | 3mm | It is suitable for slitting stainless steel sheets with a thickness of about 0.5 - 1.5 mm to ensure that the cutting edges of the product assembly are neat. |

| 105mm | 52mm | 5mm | Used for slitting low - carbon steel sheets with a thickness of 1 - 2mm in the light metal processing industry, such as the production of simple metal stamping parts. |

| 120mm | 60mm | 5mm | Ideal for slitting thin alloy steel sheets in the precision machinery manufacturing industry, for components that demand high - quality cutting surfaces |

| 160mm | 80mm | 5mm | Suited for slitting thin - walled stainless steel pipes with a wall thickness of 1 - 3mm in the plumbing and sanitary ware industry, ensuring accurate cutting dimensions. |

| 200mm | 100mm | 5mm | It is suitable for the slitting of medium and thin hot-rolled steel plates with a thickness of 1.5 - 3mm for subsequent parts that need to be bent or welded |

| 220mm | 120mm | 5mm | Used for slitting thin - to - medium - thickness carbon steel sheets in the construction of small - sized metal structures, such as the framework of small - scale storage racks. |

When customizing, it is necessary to provide the drawings or specific parameters of the cutting tool Please measure the specifications that are suitable for the mechanical blade before customization(Parameters such as diameter, inner diameter, thickness, and punching)

Our advantages

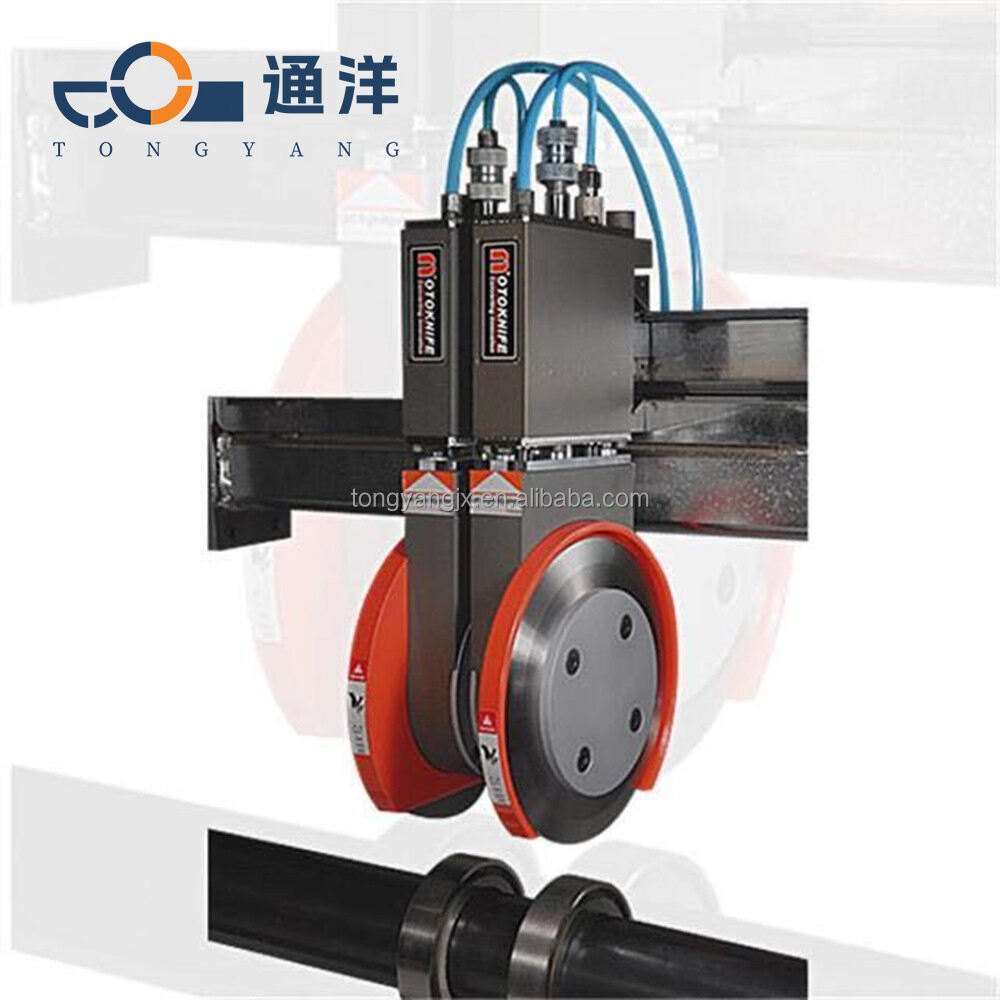

The longitudinal shearing machine blades we produce are compatible with various types of metal slitting machines on the market. They have passed strict in - machine tests to ensure stable and efficient operation.

Smooth cutting can be achieved when slitting materials such as copper, aluminum, stainless steel, and low carbon steel, providing a reliable guarantee for your production and processing.