Round vs Straight Blades: Which Slit Film Cleaner

When it comes to slitting film—whether plastic, vinyl, or packaging materials—the type of blade used directly impacts the quality of the cut, including how cleanly the film is slit. Round blades and straight blades are the two most common options for film slitting, each with unique designs that affect their ability to produce clean edges, reduce debris, and handle different film types. A clean slit is critical for film performance: rough edges can cause jams in machinery, reduce product quality, or even lead to film tearing during use. This guide compares round blades and straight blades, focusing on which one slits film cleaner, their strengths, weaknesses, and best applications.

How Blade Design Affects Film Slitting Cleanliness

The design of a blade—its shape, edge geometry, and how it interacts with the film—determines how cleanly it cuts. For film slitting, two key factors influence cleanliness:

- Cutting Action: Round blades rotate to slice through film, while straight blades use a fixed, linear motion to shear or cut. This difference in action affects how the blade interacts with the film’s surface and layers.

- Edge Pressure Distribution: A blade that distributes pressure evenly across the film’s thickness is less likely to stretch, tear, or leave jagged edges. Uneven pressure can cause the film to bunch, melt (in heat-sensitive materials), or fray.

- Debris Control: Clean slitting minimizes film dust, fragments, or “stringing” (thin plastic strands left behind). Blades that reduce friction and heat are better at controlling debris, as excessive heat can melt film edges, creating mess.

Understanding these factors helps explain why round and straight blades perform differently when slitting film.

Round Blades for Slitting Film: How They Work and Their Cleanliness

Round blades are circular, rotating tools that slit film by spinning against a fixed anvil or another rotating blade. They are widely used in industrial film slitting machines due to their efficiency and versatility.

Design and Cutting Action of Round Blades

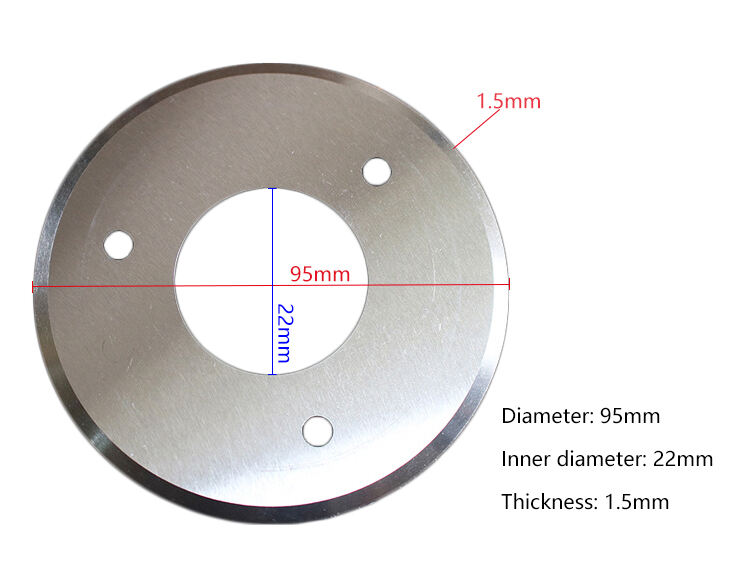

A round blade has a sharp, continuous edge that rotates at high speeds. When slitting film, the blade’s rotation creates a slicing action, cutting through the material in a smooth, continuous motion. The blade’s diameter (usually 2–12 inches) and thickness vary based on the film type—thicker blades for heavy-duty films, thinner blades for delicate materials.

Why Round Blades Slit Film Cleanly

- Continuous Slicing Motion: The rotating edge of a round blade cuts film in a single, fluid motion, reducing the risk of jagged edges. This is especially important for thin or stretchy films (like polyethylene), which can tear if pulled or stretched during cutting.

- Even Pressure Distribution: Round blades apply consistent pressure across the film’s width as they rotate, preventing uneven stretching or bunching. This even pressure ensures the film is cut straight and clean, without fraying.

- Reduced Heat Buildup: The rotating action of round blades generates less friction than some straight blade designs, minimizing heat. This is critical for heat-sensitive films (like PVC or shrink wrap), as excessive heat can melt edges, causing them to stick or form stringy residues.

- Compatibility with High Speeds: Round blades handle high-speed slitting (up to hundreds of feet per minute) without losing cutting quality. At these speeds, they maintain a clean cut, making them ideal for large-scale production.

Limitations of Round Blades for Clean Slitting

- Setup Complexity: Achieving a clean cut with round blades requires precise alignment with the anvil or opposing blade. Misalignment can cause uneven edges or film damage.

- Edge Wear Impact: As round blades wear, their edges can become dull or nicked, leading to rougher cuts. Regular sharpening is needed to maintain cleanliness, especially when slitting abrasive films (like reinforced plastic).

Straight Blades for Slitting Film: How They Work and Their Cleanliness

Straight blades are flat, fixed blades (or blades with limited back-and-forth motion) that slit film using a shearing or guillotine-like action. They are common in manual or low-speed film slitting applications.

Design and Cutting Action of Straight Blades

A straight blade has a long, linear edge that remains stationary or moves in a straight line to cut through film. In some machines, the film is fed against the fixed blade, while in others, the blade lowers onto the film like a guillotine. Straight blades are often thinner than round blades, with sharp edges designed for precision.

Why Straight Blades Slit Film Cleanly

- Precision for Thin Films: Straight blades excel at slitting very thin films (like plastic wrap or laminating films) where a fixed, sharp edge can make a clean, narrow cut without stretching the material.

- Controlled Cutting Speed: In low-speed applications, straight blades allow operators to control the cutting motion, reducing the risk of tearing delicate films. This makes them useful for small-batch or custom slitting jobs.

- Easy Maintenance: Straight blades are simpler to sharpen and align than round blades, making it easier to maintain a sharp edge—key for clean cuts. A well-sharpened straight blade can produce consistently clean edges on non-stretchy films.

Limitations of Straight Blades for Clean Slitting

- Uneven Pressure on Stretchy Films: Straight blades apply pressure at a single point as they cut, which can stretch or distort stretchy films (like polyethylene or rubberized films). This stretching leads to uneven edges or “necking” (thinning of the film near the cut).

- Heat and Friction Issues: In high-speed applications, straight blades generate more friction than round blades, increasing heat. This can melt film edges, especially in PVC or polypropylene, leaving messy residues or stuck edges.

- Slower Production Speeds: Straight blades are less efficient at high speeds, as their linear motion can’t keep up with the continuous feed of film without sacrificing cut quality. This makes them unsuitable for large-scale production where clean, fast cuts are needed.

Comparing Cleanliness: Round Blades vs Straight Blades in Different Film Types

The cleanliness of the slit depends on the film type, as different materials respond differently to cutting actions. Here’s how round and straight blades perform with common film types:

Thin, Stretchy Films (Polyethylene, Polypropylene)

- Round Blades: Their continuous rotation and even pressure prevent stretching, producing clean, straight edges without fraying. They are far more effective than straight blades for these films.

- Straight Blades: Tend to stretch the film during cutting, leading to uneven edges or tearing. Not recommended for thin, stretchy materials unless used at very low speeds.

Thick or Reinforced Films (Tarpaulin, Industrial Plastic Sheeting)

- Round Blades: Their powerful slicing action cuts through thick layers cleanly, even when the film contains reinforcing fibers. The rotating edge avoids “pushing” the film, which can cause bunching.

- Straight Blades: Can cut thick films but may require more pressure, leading to uneven edges or blade drag. They work better for non-reinforced thick films but struggle with fibers or multi-layered materials.

Heat-Sensitive Films (PVC, Shrink Wrap)

- Round Blades: Lower friction and heat buildup prevent melting, keeping edges clean and free of stringy residues. This makes them ideal for heat-sensitive films.

- Straight Blades: Higher friction generates heat, which can melt film edges, causing sticking or messy cuts. Only suitable for low-speed slitting of these materials.

Thin, Rigid Films (Laminating Films, Packaging Foils)

- Round Blades: Work well, but may be overkill for very thin, rigid films. Their clean slicing action still produces good results.

- Straight Blades: Excel here, as the rigid film doesn’t stretch. A sharp straight blade can make precise, clean cuts at low speeds, matching or exceeding round blade quality.

When to Choose Round Blades for Clean Film Slitting

Round blades are the better choice for clean film slitting in most industrial and high-volume applications, especially when:

- Slitting thin, stretchy, or heat-sensitive films.

- Operating at high speeds (over 50 feet per minute).

- Working with thick, reinforced, or multi-layered films.

- Consistency and minimal debris are critical (e.g., medical packaging, food wrapping).

When to Choose Straight Blades for Clean Film Slitting

Straight blades are preferable in specific, low-volume or specialized scenarios:

- Slitting thin, rigid films (like laminates or foils) at low speeds.

- Performing manual or small-batch slitting where precision control is more important than speed.

- Working with non-stretchy, non-heat-sensitive films (like certain types of paper-backed plastic).

FAQ

Do round blades require more maintenance than straight blades to stay clean?

Round blades need regular sharpening and alignment to maintain clean cuts, but their design makes them more forgiving in high-speed use. Straight blades are easier to sharpen but require careful handling to avoid nicks that ruin cut quality.

Can straight blades ever slit stretchy films cleanly?

Only at very low speeds with extreme precision. Even then, they are prone to stretching the film, making round blades a better choice for stretchy materials.

Why do round blades produce less debris than straight blades?

Their rotating action cuts film smoothly without tearing, reducing dust and fragments. Straight blades can shear or pull film, creating more debris, especially in thick materials.

Are there hybrid blades that combine round and straight features?

Yes, some machines use “rotary straight blades,” which combine a straight edge with rotation. These work well for certain films but are less common than traditional round blades.

How does blade sharpness affect clean slitting in both types?

Sharpness is critical for both: dull round blades create jagged edges due to uneven slicing, while dull straight blades tear or crush film. Regular sharpening is essential for clean cuts in all blade types.

Table of Contents

- Round vs Straight Blades: Which Slit Film Cleaner

- How Blade Design Affects Film Slitting Cleanliness

- Round Blades for Slitting Film: How They Work and Their Cleanliness

- Straight Blades for Slitting Film: How They Work and Their Cleanliness

- Comparing Cleanliness: Round Blades vs Straight Blades in Different Film Types

- When to Choose Round Blades for Clean Film Slitting

- When to Choose Straight Blades for Clean Film Slitting

-

FAQ

- Do round blades require more maintenance than straight blades to stay clean?

- Can straight blades ever slit stretchy films cleanly?

- Why do round blades produce less debris than straight blades?

- Are there hybrid blades that combine round and straight features?

- How does blade sharpness affect clean slitting in both types?