How do I choose the right circular blade for my material?

Choosing the right circular blade for your material is key to achieving clean cuts, reducing waste, and extending the life of your tools. Whether you’re cutting wood, metal, plastic, or fabric, the wrong circular blade can lead to ragged edges, overheating, or even damage to the material or machine. With so many options available, it’s important to understand how blade features like material, tooth count, and design interact with different materials. This guide breaks down the steps to select the perfect circular blade for your specific material, ensuring efficient and high-quality results.

Understand Your Material’s Properties

The first step in choosing a circular blade is to analyze the material you’ll be cutting. Different materials have unique characteristics that demand specific blade features:

- Hardness: Hard materials (like metal or stone) require blades with tough, wear-resistant materials to avoid dulling. Soft materials (like wood or fabric) need blades that cut cleanly without tearing.

- Density: Dense materials (like hardwood or thick plastic) need blades with aggressive cutting action to slice through efficiently. Less dense materials (like softwood or foam) require blades that prevent splintering or crushing.

- Abrasiveness: Abrasive materials (like fiberglass or concrete) wear down blades quickly, so they need blades with extra-hard tips or coatings. Non-abrasive materials (like aluminum or vinyl) are easier on blades but still require proper tooth design.

- Flexibility: Flexible materials (like rubber or fabric) can stretch or bunch during cutting, requiring blades with sharp, fine teeth to minimize distortion. Rigid materials (like metal or ceramic) need blades that apply steady pressure without chipping.

By identifying these properties, you can narrow down the blade features that matter most for your material.

Key Circular Blade Features to Consider

Circular blades vary in several key features, each designed to optimize performance for specific materials. Here’s how to match these features to your needs:

Blade Material

The material of the circular blade itself determines its durability and cutting ability:

- High-Carbon Steel: Affordable and sharp, ideal for cutting softwoods, plywood, and non-abrasive plastics. It dulls quickly on hard or abrasive materials but works well for light-duty projects.

- High-Speed Steel (HSS): Harder than high-carbon steel, with better heat resistance. Suitable for cutting hardwoods, aluminum, and thin metals. It lasts longer than high-carbon steel but is less durable than carbide.

- Carbide-Tipped: Steel blades with tungsten carbide tips (one of the hardest materials available). Excellent for abrasive materials like particleboard, fiberglass, and thick metals. They stay sharp 5–10 times longer than steel blades but cost more upfront.

- Ceramic-Coated: Steel blades with a ceramic layer for reduced friction and heat resistance. Good for cutting heat-sensitive materials like PVC or shrink wrap, as they minimize melting.

How to choose: For soft, non-abrasive materials, high-carbon steel works. For hardwoods or metals, use HSS. For abrasive or heavy-duty materials, carbide-tipped is best. For heat-sensitive materials, opt for ceramic-coated.

Tooth Count and Design

The number of teeth and their shape (tooth design) directly affect cut quality and speed:

- Tooth Count: Measured as teeth per inch (TPI). Blades with fewer teeth (10–24 TPI) cut faster but leave rougher edges, making them ideal for ripping wood or cutting thick materials. Blades with more teeth (40–80 TPI) cut slower but produce smoother edges, perfect for crosscutting wood or finishing cuts on metal.

-

Tooth Design:

- Flat Top Grind (FTG): Flat, square teeth for aggressive cutting with the grain (ripping wood) or through thick materials. They remove material quickly but may leave rough edges.

- Alternate Top Bevel (ATB): Teeth angled alternately (left and right) for clean crosscuts in wood or plastic. They slice through fibers to prevent splintering.

- Triple Chip Grind (TCG): A mix of flat and beveled teeth, designed for cutting hard materials like metal, laminate, or particleboard. They resist chipping and handle abrasives well.

- Zero-Clearance: Very fine, closely spaced teeth for cutting delicate materials like fabric or thin plastic without tearing.

How to choose: Use low TPI with FTG teeth for fast, rough cuts in thick materials. Use high TPI with ATB teeth for smooth, precise cuts in wood or plastic. For hard/abrasive materials, use TCG teeth with moderate TPI (24–40). For delicate materials, choose high TPI with zero-clearance design.

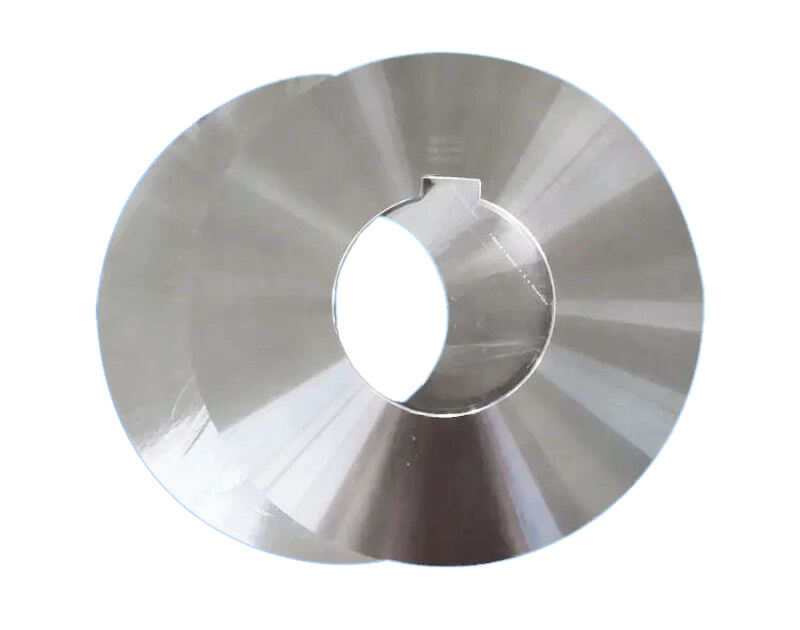

Blade Diameter and Thickness

- Diameter: Larger blades (10–14 inches) cut deeper, making them suitable for thick materials like lumber or metal sheets. Smaller blades (4–7 inches) are for portable saws or cutting thin materials like plywood or aluminum.

- Thickness: Thicker blades (0.08–0.12 inches) are more durable for heavy-duty cutting but create wider cuts (kerfs), wasting more material. Thinner blades (0.04–0.07 inches) make narrower cuts, saving material, but are more prone to bending in thick materials.

How to choose: Match diameter to material thickness—larger blades for deep cuts. Use thicker blades for heavy, abrasive materials; thinner blades for light, delicate materials to reduce waste.

Hook Angle

The hook angle (the angle of the tooth face relative to the blade’s center) affects how the blade pulls material:

- Positive Hook Angle (5–20 degrees): Teeth pull material into the blade aggressively, cutting faster. Good for softwoods, plastics, and materials that need quick removal.

- Neutral Hook Angle (0 degrees): Teeth cut without pulling, reducing the risk of splintering. Ideal for hardwoods, laminates, and thin metals.

- Negative Hook Angle (-5 to -15 degrees): Teeth push material away slightly, minimizing chipping and heat. Best for hard materials like metal, ceramic, or abrasive composites.

How to choose: Positive angles for fast cuts in soft materials. Neutral angles for balanced cuts in hardwoods or laminates. Negative angles for hard, brittle, or heat-sensitive materials.

Matching Circular Blades to Specific Materials

Here’s a breakdown of the best circular blades for common materials:

Wood (Softwood and Hardwood)

- Softwood (pine, fir): High-carbon steel or HSS blade with 24–40 TPI, FTG or ATB teeth, and positive hook angle. For rough cuts, use lower TPI; for smoother cuts, higher TPI.

- Hardwood (oak, maple): HSS or carbide-tipped blade with 40–60 TPI, ATB teeth, and neutral hook angle. Carbide-tipped blades last longer on dense hardwoods.

- Plywood or MDF: Carbide-tipped blade with 40–60 TPI, TCG or ATB teeth, and neutral hook angle. These materials are abrasive, so carbide resists wear.

Metal (Steel, Aluminum, Copper)

- Thin Metal (sheet steel, aluminum): HSS or carbide-tipped blade with 60–80 TPI, TCG teeth, and negative hook angle. High TPI ensures smooth cuts without burring.

- Thick Metal (steel bars, pipes): Carbide-tipped blade with 10–24 TPI, TCG teeth, and negative hook angle. Lower TPI allows faster cutting through thick material.

Plastic and PVC

- Thick Plastic (PVC pipes, acrylic sheets): Carbide-tipped or ceramic-coated blade with 40–60 TPI, ATB teeth, and neutral hook angle. Ceramic coating reduces heat to prevent melting.

- Thin Plastic (packaging, vinyl): High-carbon steel blade with 60–80 TPI, zero-clearance teeth, and positive hook angle. Fine teeth prevent tearing.

Abrasive Materials (Fiberglass, Particleboard, Concrete)

- Fiberglass or Composite Panels: Carbide-tipped blade with 24–40 TPI, TCG teeth, and negative hook angle. Carbide resists abrasion from glass fibers.

- Particleboard or OSB: Carbide-tipped blade with 40–60 TPI, TCG teeth, and neutral hook angle. These materials are abrasive and can dull steel blades quickly.

Delicate Materials (Fabric, Foam, Thin Leather)

- Fabric or Foam: High-carbon steel blade with 80–100 TPI, zero-clearance teeth, and positive hook angle. Very fine teeth cut without snagging or tearing.

- Thin Leather or Vinyl: HSS blade with 60–80 TPI, ATB teeth, and neutral hook angle. Smooth teeth prevent stretching or distortion.

Additional Tips for Choosing the Right Circular Blade

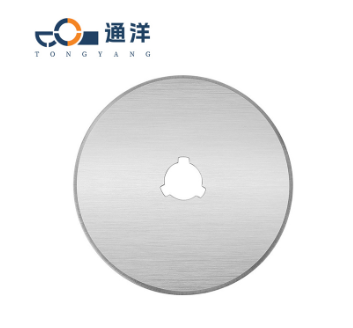

- Check Saw Compatibility: Ensure the blade’s diameter and arbor size (the hole in the center) match your saw. Most circular saws use 7–10 inch blades with 5/8 inch arbors.

- Consider Cutting Speed: For production or large projects, prioritize faster-cutting blades (lower TPI). For finish work, prioritize smoothness (higher TPI).

- Test on Scrap Material: If unsure, test the blade on a scrap piece of your material. Check for smooth edges, minimal waste, and no overheating.

- Maintain Blades Properly: Even the best blade will underperform if dull. Clean and sharpen blades regularly, or replace them when they show signs of wear (ragged cuts, burning, or slow cutting).

FAQ

Can I use the same circular blade for different materials?

It’s not recommended. Blades designed for one material (like wood) will dull quickly or produce poor cuts on another (like metal). Using the wrong blade can also damage your saw or material.

How do I know if a blade is too dull for my material?

Signs include ragged edges, burning marks on the material, increased effort to cut, or loud, uneven noises during cutting. Dull blades should be sharpened or replaced.

Is a carbide-tipped blade worth the extra cost?

Yes, for abrasive or hard materials. Carbide-tipped blades last much longer than steel blades, saving money on replacements in the long run, especially for frequent use.

What’s the best tooth count for cutting plywood?

40–60 TPI is ideal. This balance of teeth provides smooth cuts without bogging down in the layers of plywood, reducing splintering.

How does hook angle affect cutting plastic?

A neutral or negative hook angle is best for plastic. Positive angles can pull the material too aggressively, causing melting or rough edges, especially in PVC.