Do Precision Round Blades Cut Downtime in Film Slitting?

In film slitting operations—whether for packaging, plastics, or industrial materials—downtime is a major cost driver. Every minute a machine stops for blade changes, adjustments, or repairs eats into productivity and profits. Precision round blades, designed for accuracy, durability, and consistent performance, are often promoted as a solution to reduce this downtime. But do they truly deliver? The answer is yes: precision round blades cut downtime in film slitting by minimizing interruptions, improving reliability, and extending intervals between maintenance. This guide explores how precision round blades reduce downtime, the features that make them effective, and real-world benefits for film slitting operations.

What Are Precision Round Blades?

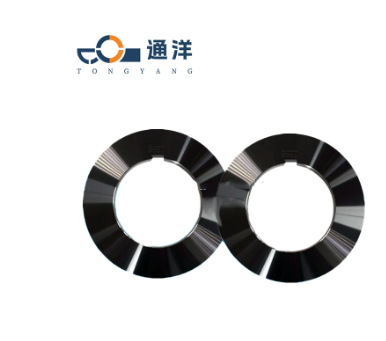

Precision round blades are circular cutting tools engineered to strict tolerances, ensuring uniform edge geometry, balanced rotation, and consistent performance. Unlike standard round blades, which may have slight variations in thickness, sharpness, or alignment, precision round blades are manufactured with advanced techniques (like laser cutting or grinding) to meet exact specifications. Key features include:

- Uniform Edge Sharpness: The cutting edge is ground to a precise angle and finish, ensuring every part of the blade cuts with equal efficiency.

- Balanced Rotation: The blade is weighted evenly to prevent vibration during high-speed rotation, reducing wear and ensuring stable cutting.

- High-Quality Materials: Made from durable materials like high-carbon steel, carbide-tipped steel, or ceramic-coated alloys, designed to resist wear and maintain sharpness longer.

- Tight Tolerances: Dimensions (diameter, thickness, hole size) are controlled to within tiny margins (often +/- 0.001 inches), ensuring perfect fit with slitting machines.

These features make precision round blades reliable workhorses in film slitting, where consistency is critical to avoiding downtime.

How Precision Round Blades Reduce Downtime in Film Slitting

Downtime in film slitting comes from three main sources: blade changes, machine adjustments, and quality-related stops (like reworking flawed cuts). Precision round blades address all three, cutting downtime significantly.

Fewer Blade Changes: Extended Sharpness and Wear Resistance

Standard round blades dull quickly, especially when slitting abrasive films (like reinforced plastics) or high-volume materials. Dull blades produce ragged cuts, forcing operators to stop the machine, remove the old blade, and install a new one—each change taking 15–30 minutes or more.

Precision round blades, by contrast, maintain sharpness longer:

- High-Quality Materials: Carbide-tipped or ceramic-coated precision blades resist abrasion, staying sharp 5–10 times longer than standard steel blades. For example, a precision carbide round blade slitting corrugated plastic film may last 8–12 weeks, while a standard blade needs replacement every 1–2 weeks.

- Uniform Edge Wear: Their consistent edge geometry ensures even wear, so the blade remains effective until nearly the end of its life. Standard blades often wear unevenly, becoming unusable early due to nicks or dull spots.

Fewer blade changes mean less downtime: a facility slitting 8 hours daily could save 2–4 hours weekly by switching to precision round blades, simply by reducing the number of blade replacements.

Reduced Machine Adjustments: Consistent Fit and Performance

Standard round blades often have slight variations in size or balance, requiring operators to adjust machine settings (like pressure, speed, or alignment) each time a new blade is installed. These adjustments take time and can lead to trial-and-error runs, wasting film and creating more downtime.

Precision round blades minimize adjustments:

- Tight Tolerances: Their consistent dimensions (diameter, thickness, hole size) ensure a perfect fit in the machine every time. No need to tweak alignment or pressure when installing a new precision blade.

- Balanced Rotation: Precision blades are dynamically balanced, reducing vibration during high-speed slitting. Vibration from unbalanced standard blades can loosen machine parts over time, requiring frequent re-calibration—another source of downtime.

With precision round blades, operators spend less time adjusting machines and more time producing. A study in a packaging plant found that switching to precision blades reduced setup time per blade change by 70%, from 20 minutes to just 6 minutes.

Fewer Quality Stops: Clean Cuts and Reduced Waste

Poorly cut film—with jagged edges, tears, or uneven widths—forces operators to stop the machine, inspect the issue, and often rework or discard flawed material. Standard blades, with their inconsistent edges, are a common cause of these quality-related stops.

Precision round blades reduce quality stops by producing cleaner, more consistent cuts:

- Uniform Cutting Action: Their sharp, even edges slit film cleanly, reducing the risk of jams (caused by ragged edges catching in machinery) or rejects (films that don’t meet width or quality standards).

- Reduced Film Waste: Clean cuts mean less material is discarded due to defects. A plastics manufacturer reported a 30% reduction in film waste after switching to precision round blades, as fewer rolls were scrapped for poor edge quality.

- Stable Performance at High Speeds: Precision blades maintain cut quality even at high speeds (up to 500 feet per minute), while standard blades may start to “chatter” or produce uneven cuts, forcing operators to slow down or stop.

By minimizing quality issues, precision round blades keep machines running longer between stops. In one industrial film plant, downtime due to quality checks and rework dropped by 40% after adopting precision blades.

Real-World Impact: Downtime Savings with Precision Round Blades

To illustrate the impact, consider a mid-sized film slitting facility running two machines 8 hours a day, 5 days a week:

- With Standard Blades: Each machine stops 3 times weekly for blade changes (30 minutes each), 2 times weekly for adjustments (20 minutes each), and 4 times weekly for quality issues (15 minutes each). Total weekly downtime per machine: 330 + 220 + 4*15 = 90 + 40 + 60 = 190 minutes. For two machines: 380 minutes (6.3 hours).

- With Precision Round Blades: Blade changes drop to 1 per week (30 minutes), adjustments to 1 per week (6 minutes), and quality stops to 1 per week (15 minutes). Total weekly downtime per machine: 30 + 6 + 15 = 51 minutes. For two machines: 102 minutes (1.7 hours).

This facility saves 4.6 hours of downtime weekly—over 239 hours annually—by switching to precision round blades. At an average production rate of $200 per hour, this translates to over $47,000 in recovered productivity yearly.

Choosing the Right Precision Round Blade for Your Needs

To maximize downtime savings, select a precision round blade tailored to your film type:

- Carbide-Tipped Precision Blades: Best for abrasive films (reinforced plastics, coated films) or high-volume slitting. They offer the longest wear life.

- High-Speed Steel (HSS) Precision Blades: Suitable for non-abrasive films (polyethylene, PVC) where cost is a factor. They last longer than standard steel but less than carbide.

- Ceramic-Coated Precision Blades: Ideal for heat-sensitive films (shrink wrap, laminates). The ceramic layer reduces friction and heat, preventing edge melting.

Always match the blade’s hardness and edge angle to your film: harder blades for thick/abrasive films, sharper angles for thin/delicate films.

FAQ

How much more do precision round blades cost than standard blades?

Precision round blades cost 2–3 times more upfront, but their extended lifespan and downtime savings make them cheaper in the long run. Most facilities recoup the extra cost within 1–2 months.

Can precision round blades work in any slitting machine?

Yes, as long as the blade dimensions match the machine’s specifications. Precision blades are made to standard sizes but with tighter tolerances, ensuring compatibility.

Do precision round blades require special maintenance?

No—they need the same care as standard blades (regular cleaning, proper storage), but their durability means less frequent sharpening or replacement.

Will precision blades reduce downtime in low-volume operations?

Yes, though savings are smaller. Even low-volume facilities benefit from fewer blade changes and adjustments, freeing up operator time.

How do I know if my current downtime is due to blade issues?

Signs include frequent blade changes, uneven cuts, machine vibrations, or operators spending more time adjusting settings than running production.

Table of Contents

- Do Precision Round Blades Cut Downtime in Film Slitting?

- What Are Precision Round Blades?

- How Precision Round Blades Reduce Downtime in Film Slitting

- Real-World Impact: Downtime Savings with Precision Round Blades

- Choosing the Right Precision Round Blade for Your Needs

-

FAQ

- How much more do precision round blades cost than standard blades?

- Can precision round blades work in any slitting machine?

- Do precision round blades require special maintenance?

- Will precision blades reduce downtime in low-volume operations?

- How do I know if my current downtime is due to blade issues?