Are Custom Round Blades Worth It for Food Packaging?

In food packaging, precision and efficiency are critical. Every cut must be clean to maintain product freshness, prevent contamination, and ensure packages seal properly. Standard round blades, while widely available, may not always meet the unique needs of specific food packaging materials or machinery. Custom round blades—designed to match exact dimensions, materials, and cutting requirements—are often considered as an upgrade. But are they worth the investment? For many food packaging operations, the answer is yes: custom round blades improve cut quality, reduce waste, and enhance efficiency, making them a valuable long-term solution. This guide explores why custom round blades matter for food packaging, their benefits, and when they justify the extra cost.

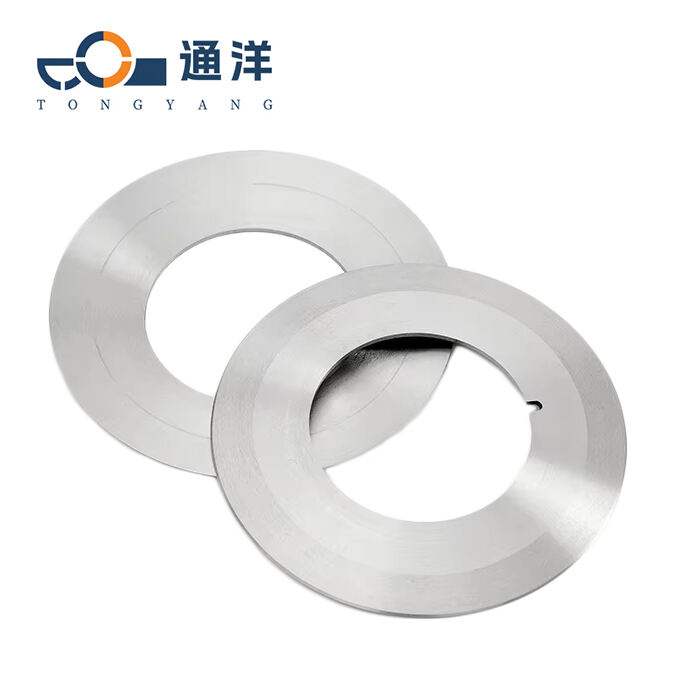

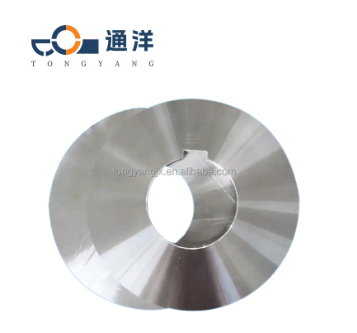

What Are Custom Round Blades for Food Packaging?

Custom round blades are circular cutting tools engineered to specific specifications for food packaging applications. Unlike off-the-shelf blades, which come in standard sizes and designs, custom blades are tailored to:

- Unique Machinery: Fit perfectly with specialized packaging equipment, such as vertical form-fill-seal (VFFS) machines, flow wrappers, or tray sealers.

- Specific Materials: Cut through particular food packaging materials, like thin films (plastic wrap), thick laminates (foil-backed pouches), or paper-based materials (cardboard boxes).

- Precise Cuts: Achieve exact cut widths, edge finishes, or perforations required for packaging designs (e.g., easy-open tabs, resealable closures).

- Food Safety Standards: Use materials approved for food contact (like stainless steel or food-grade coatings) to avoid contamination risks.

Manufacturers create custom round blades by adjusting features like diameter, thickness, tooth design, material, and coating to match the customer’s unique needs.

How Custom Round Blades Improve Food Packaging Performance

Food packaging faces unique challenges: materials range from delicate films to tough laminates, machines run at high speeds, and safety standards are strict. Custom round blades address these challenges better than standard blades, leading to tangible improvements.

Cleaner Cuts for Freshness and Safety

Food packaging must seal tightly to keep products fresh and prevent bacterial contamination. A clean cut is essential—ragged edges or uneven seals can cause leaks, spoilage, or packaging failure.

Standard blades often struggle with specific materials:

- Thin plastic films may stretch or tear, leaving jagged edges that prevent proper sealing.

- Laminated materials (like paper-plastic composites) can delaminate when cut with the wrong blade, creating loose layers that trap food particles.

- Thick materials may require excessive pressure, causing the blade to drag and leave uneven edges.

Custom round blades solve these issues by:

- Using tooth designs matched to the material (e.g., fine, sharp teeth for thin films to prevent stretching; aggressive teeth for thick laminates to cut cleanly).

- Ensuring precise blade thickness to avoid material distortion—too thick, and the blade crushes the material; too thin, and it bends under pressure.

- Incorporating coatings (like Teflon) to reduce friction, preventing plastic films from melting or sticking to the blade during high-speed cutting.

Cleaner cuts mean better seals, longer shelf life for food products, and fewer rejected packages due to poor quality.

Reduced Waste and Material Savings

In food packaging, waste comes from two sources: damaged packaging materials (due to poor cuts) and excess material trimmed away during production. Custom round blades minimize both.

Standard blades often produce inconsistent cuts, leading to:

- Over-trimming to compensate for uneven edges, wasting valuable packaging material.

- Scrap from torn or misaligned cuts, which increases material costs and disposal needs.

Custom round blades reduce waste by:

- Cutting to exact dimensions, eliminating the need for over-trimming. For example, a custom blade designed to cut a 4-inch pouch will produce consistent 4-inch cuts, reducing trim waste by up to 10–15% in some operations.

- Minimizing tearing or stretching, so fewer packages are discarded due to defects. A bakery using custom blades for pastry boxes reported a 20% drop in scrap material after switching from standard blades.

- Enabling precise perforations or partial cuts (e.g., for easy-open packaging), which reduces the risk of damaging the package during opening—further lowering waste.

Over time, these savings add up, offsetting the higher upfront cost of custom blades.

Longer Lifespan and Fewer Changeovers

Downtime for blade changes is a major cost in food packaging, where machines run continuously to meet demand. Standard blades often dull quickly, especially when cutting abrasive materials like coated papers or reinforced films, requiring frequent stops for replacements.

Custom round blades extend intervals between changes by:

- Using harder, more wear-resistant materials (like carbide-tipped stainless steel) tailored to the packaging material. For example, a custom carbide blade cutting foil-laminated pouches may last 3–5 times longer than a standard steel blade.

- Incorporating balanced designs to reduce vibration during high-speed rotation. Vibration wears down standard blades quickly, but custom blades with precise balancing stay sharp longer.

- Matching the blade’s hardness to the material—softer blades for delicate films (to avoid chipping) and harder blades for abrasives (to resist wear).

Fewer blade changes mean less downtime, higher productivity, and lower labor costs for maintenance. A snack packaging plant reported reducing blade change time by 50% after switching to custom blades, as they needed replacement only once every two weeks instead of twice weekly.

Compliance with Food Safety Standards

Food packaging is governed by strict safety regulations (like FDA standards in the U.S.) that prohibit contamination from packaging materials or tools. Standard blades may use materials or coatings that are not food-safe, risking product recalls or health violations.

Custom round blades are designed with safety in mind:

- Made from food-grade materials, such as 304 stainless steel (resistant to corrosion and rust) or carbide tips bonded with food-safe adhesives.

- Coated with non-toxic, FDA-approved finishes (like Teflon) that prevent bacteria buildup and avoid transferring chemicals to food.

- Manufactured in cleanroom environments to avoid contamination during production, ensuring blades are ready for use in hygienic packaging lines.

For brands prioritizing safety, custom blades reduce the risk of non-compliance and protect against costly recalls.

When Custom Round Blades Are Worth the Investment

Custom round blades are not necessary for every food packaging operation, but they are worth the cost in specific scenarios:

Specialized Materials or Unique Packaging Designs

If your operation uses non-standard materials (e.g., biodegradable films, metalized laminates) or produces custom packaging (e.g., shaped pouches, resealable bags with unique closures), standard blades may struggle to deliver clean cuts. Custom blades tailored to these materials or designs will improve quality and reduce waste.

High-Volume Production Lines

In facilities running 24/7 or producing large volumes, downtime and waste have a bigger impact on profits. Custom blades’ longer lifespan and reduced changeover time translate to significant savings in high-volume settings.

Strict Quality or Safety Requirements

Brands with strict quality standards (e.g., organic food producers, medical food manufacturers) or those facing frequent audits benefit from custom blades’ consistent performance and food-safe materials, reducing the risk of defects or safety violations.

When Standard Blades Cause Recurring Issues

If your operation struggles with frequent blade changes, poor cut quality, or high waste using standard blades, custom blades can solve these recurring problems, justifying their cost.

When Standard Blades May Be Sufficient

For small operations using common materials (e.g., standard plastic bags, basic cardboard boxes) and low production volumes, standard blades may be adequate. They are cheaper upfront and work well enough for simple packaging needs where minor defects or occasional waste are acceptable.

FAQ

How much more do custom round blades cost than standard blades?

Custom round blades typically cost 2–5 times more upfront than standard blades. However, their longer lifespan, reduced waste, and lower downtime often make them cheaper over time, especially in high-volume operations.

How long does it take to get custom round blades made?

Lead times for custom blades range from 2–6 weeks, depending on complexity. Many manufacturers offer rush options for urgent needs, though this may increase costs.

Can custom blades be reused or resharpened?

Yes, most custom round blades (especially those made from high-quality steel or carbide) can be resharpened 2–5 times, extending their lifespan further. Manufacturers often provide sharpening services for their custom blades.

Do custom blades work with any packaging machine?

Custom blades are designed to fit specific machines, so they must be engineered to match your equipment’s specifications (e.g., arbor size, rotation speed). Providing machine details to the manufacturer ensures compatibility.

Are custom blades only for large companies?

No, even small operations can benefit from custom blades if they face specific challenges (e.g., unique materials or recurring quality issues). Many manufacturers offer custom solutions for businesses of all sizes.