Factors Influencing Paper Roll Blade Replacement Intervals

Material Composition and Blade Longevity

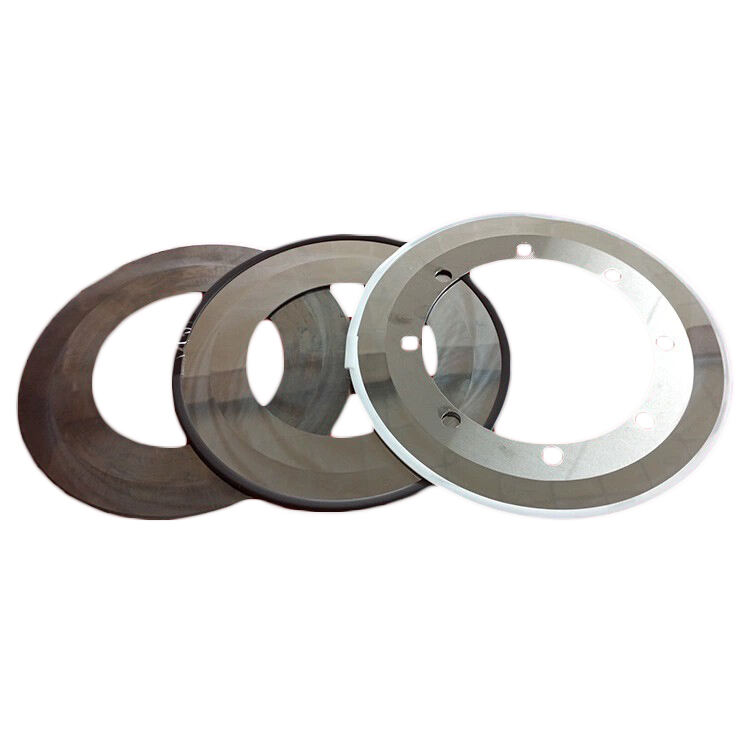

The materials used in manufacturing paper roll cutting blades play a crucial role in their longevity. Blades made from high-carbon steel are often compared with carbide-tipped blades for their durability. Research shows that blades composed of premium materials, such as tungsten carbide, can last 2-3 times longer than those made from less robust materials. This prolonged lifespan not only reduces the frequency of replacements but also leads to economic savings over time. Additionally, understanding the interaction between blade material and paper type is essential for optimizing replacement schedules. For example, using high-speed steel for light-duty tasks can prevent unnecessary wear and prolong blade life.

Operational Frequency and Workload Demands

The frequency of operations significantly impacts the replacement intervals of paper roll cutting blades. In environments where blades are utilized frequently and with high demand, replacements may be required after every 500 to 1,000 cuts to maintain efficiency and precision. Conversely, blades used in less demanding applications can last longer before needing replacements. Recording operational data is a valuable practice, as it helps in assessing wear rates and predicting when a blade might need to be replaced. Such records ensure that machinery downtime is minimized and that blades are performing optimally at all times.

Environmental Conditions Impacting Blade Wear

Environmental conditions are fundamental to understanding blade wear. Elements like humidity and temperature can accelerate the deterioration of paper roll cutting blades, especially in wet conditions, which may lead to corrosion. Studies suggest that environmental factors can cause blades used in severe conditions to wear out 30-50% faster than those in controlled environments. This makes it critical to identify these impacts, which allows for the creation of tailored maintenance schedules that consider specific working settings. Such proactive measures can effectively manage wear and extend the lifespan of paper roll blades even in challenging conditions.

Recognizing Signs of a Dull or Worn-Out Blade

Visible Blade Damage and Edge Deformation

Visible signs of damage on paper roll cutting blades, such as chips or bends, are indicators of potential operational hazards. Regular visual inspections can help identify such damages early on, preventing safety risks and maintaining the efficiency of the cutting process. Noticing visual indicators of wear before there's a noticeable performance drop is key, especially in high-volume operations where documentation suggests weekly checks. This proactive approach can avert unexpected failures and costly downtimes.

Performance Indicators in Cutting Quality

A decline in cutting quality usually manifests as jagged or uneven edges on the paper, signifying a need for blade replacement. Such performance indicators are crucial as they often precede visible signs of wear, warning users of impending deterioration. Utilizing metrics like thickness variation can be effective in predicting the blade's condition and ensuring timely replacements. Regular inspection of the cut quality not only prolongs the blade's life but also guarantees consistent, high-quality outcomes.

Increased Production Errors and Material Waste

Worn-out blades are notorious for causing increased production errors, significantly contributing to material waste and associated costs. Statistics have shown that poor blade conditions can lead to a rise in waste levels by up to 25%. Tracking waste related to blade performance can establish trends, optimizing the timing for replacements and preventing excess wastage. By ensuring blades are in top condition, companies can minimize errors and maintain operational efficiency.

Maintenance Techniques to Prolong Blade Effectiveness

Proper Sharpening Procedures for Different Blade Types

To maximize the lifespan and effectiveness of cutting blades, it's crucial to apply proper sharpening techniques catered to each blade type. Sharpening involves specific angle adjustments to achieve optimal performance and avoid introducing microfractures during the process. Microfractures can significantly compromise a blade's structural integrity, shortening its effective lifespan. Industry best practices suggest sharpening paper roll cutting blades after a pre-defined number of cuts; this routine helps maintain cutting efficiency and prolongs the tool's usability. By adhering to these guidelines, we can ensure consistent performance and prevent premature wear.

Cleaning Protocols to Prevent Premature Dulling

Regular cleaning is essential to prevent premature blade dulling and extend the tool's functional life. Accumulation of materials like paper dust and adhesives can dramatically reduce sharpness over time if not properly managed. Using non-abrasive cleaning agents specifically recommended for cutting tools ensures the blade surfaces remain unscathed. Field studies have shown that operations employing rigorous cleaning protocols report blade lifespans extending by approximately 20%. This data underscores the significant role that dedicated maintenance routines play in maintaining blade effectiveness.

Storage Best Practices Between Operations

Proper storage of blades between operations is a key factor in preserving their edge and overall condition. Using protective sheathing minimizes exposure to environmental factors and accidental damage. It is also advised against stacking blades as this can lead to edge deformation, which is crucial to maintaining sharpness. Industry guidelines strongly recommend storing paper roll cutting blades in a cool, dry environment to avert potential deterioration. By following these storage best practices, we can substantially prolong the sharpness and functionality of the blades, ensuring they perform optimally over extended periods.

Implementing Daily Blade Performance Monitoring

Quality Control Checks for Consistent Output

Establishing routine quality control checks is critical in maintaining consistent blade performance. By conducting bi-daily inspections, including both visual assessments and cutting quality evaluations, we can identify potential performance issues before they affect the integrity of the products. This routine ensures that blades function optimally and uphold the desired standards. Additionally, logging quality control metrics allows us to track trends and anticipate predictable failures, facilitating proactive maintenance measures. Such systematic checks are integral in maintaining high-quality cut results.

Documenting Cutting Efficiency Metrics

Tracking metrics like the speed and yield of cutting operations provides valuable insights into blade performance over time. By benchmarking these metrics against historical data, we can guide decisions on when to replace blades, ensuring optimal efficiency and cost-effectiveness. Studies have shown that documenting efficiency and operational data not only supports better decision-making but also enhances accountability within maintenance programs. This systematic approach to monitoring ensures that we can maintain high standards while minimizing operational disruptions.

Early Detection Through Operator Feedback Systems

Incorporating feedback systems that empower operators to report on blade performance can lead to timely interventions and prevent larger issues. When operators feel encouraged to share their observations, it fosters a culture of safety and quality, prompting early detection of potential blade failures. Implementing formal feedback systems enhances this process, with data guiding the establishment of predictive maintenance schedules. Operator insights are invaluable for refining our approach to blade maintenance and ensuring continued operational excellence.

Creating a Data-Driven Blade Replacement Schedule

Analyzing Historical Usage Patterns

Documenting historical usage patterns of paper roll cutting blades is crucial for establishing a proactive replacement schedule. By collecting data on how blades have been used over time, we can determine their optimal replacement intervals based on actual wear and workload demands. For instance, examining past data might reveal patterns that correlate with increased wear during high production periods, allowing for better forecasting. Consistency in data collection not only supports scheduling but also aids in budgeting, ensuring funds are appropriately allocated for timely replacements.

Leveraging Maintenance Logs for Predictive Replacement

Maintenance logs, often overlooked, are a goldmine of information when it comes to scheduling blade replacements predictively. By analyzing these logs, we can identify the typical lifespan of blades and apply predictive analytics to anticipate future failures. Remarkably, studies show that 84% of companies that leverage maintenance logs report enhanced operational efficiency. This data-driven approach not only reduces downtime but also enhances the overall reliability of the machinery, contributing significantly to streamlined operations.

Customizing Intervals Based on Specific Applications

Every application can have a different impact on blade life, necessitating customized replacement intervals. Understanding these nuances allows us to tailor maintenance schedules to the unique demands of each production line. For example, applications involving harder materials might require more frequent blade replacements compared to softer materials. This flexibility can lead to substantial cost savings by avoiding unnecessary replacements while ensuring optimum performance. Custom schedules not only meet specific operational requirements but also extend the overall longevity of the equipment, providing a competitive edge in maintaining quality and efficiency.

Optimizing Blade Usage Through Operational Best Practices

Material Selection Compatibility Considerations

Selecting the right blade materials based on the type of paper being processed is crucial for optimizing paper roll cutting blade lifespan. Incompatible interactions between blade materials and specific paper types can lead to accelerated wear, thereby increasing the frequency of replacements. By understanding and applying the principles of material compatibility, we can significantly enhance production efficiency and reduce downtime.

Machine Calibration for Reduced Blade Stress

Machine calibration plays a pivotal role in ensuring that blades operate within their designed stress parameters. Regular calibration helps prevent misalignment, which can cause uneven wear and diminish the effectiveness of the blades. Implementing routine calibration checks is a straightforward measure that can substantially increase the lifespan of paper roll cutting blades and improve operational efficiency.

Operator Training for Proper Blade Handling

Investing in operator training ensures that staff understand and apply best practices when handling blades, thus minimizing the risk of accidents and damage. Proper handling techniques can mitigate common causes of blade damage, leading to improved safety and performance. Companies that prioritize operator training often report a noticeable decrease in operational costs related to blades, highlighting the value of skilled personnel in blade management systems.

FAQ Section

What material is best for paper roll cutting blades?

The best materials for paper roll cutting blades include high-carbon steel and tungsten carbide due to their durability and prolonged lifespan.

How can I detect when a blade needs replacing?

Indicators such as visible damage to the blade, a decline in cutting quality, and increased production errors suggest it may be time to replace the blade.

What environmental factors affect blade wear?

Humidity, temperature, and wet conditions can accelerate the deterioration and wear of blades, especially if not stored properly.

Why is operator feedback important in blade maintenance?

Operator feedback helps identify potential performance issues early, fostering safety and quality in blade maintenance processes.

Table of Contents

- Factors Influencing Paper Roll Blade Replacement Intervals

- Recognizing Signs of a Dull or Worn-Out Blade

- Maintenance Techniques to Prolong Blade Effectiveness

- Implementing Daily Blade Performance Monitoring

- Creating a Data-Driven Blade Replacement Schedule

- Optimizing Blade Usage Through Operational Best Practices

- FAQ Section