Can Sharpening Extend the Service Life of a Double Round-Blade?

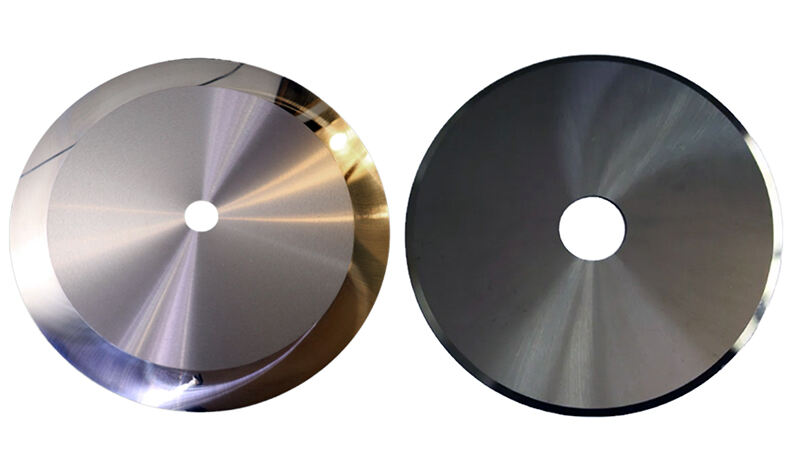

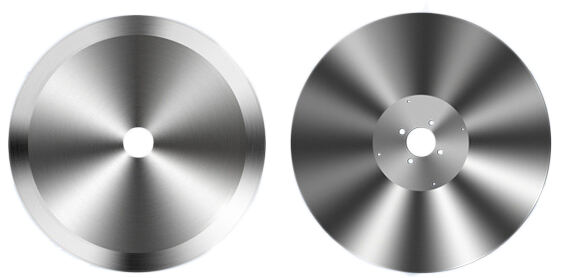

Double round-blades are essential tools in many industries, from food processing and packaging to woodworking and textiles. These blades, with their circular design and two cutting edges, rely on sharpness to perform clean, efficient cuts. Over time, even the highest-quality double round-blade becomes dull due to friction, contact with hard materials, and normal wear. A common question among users is whether sharpening can extend the service life of a double round-blade. The short answer is yes—proper sharpening not only restores a blade’s cutting ability but also significantly prolongs its useful life by reducing wear, preventing damage, and maintaining efficiency. This guide explores how sharpening affects double round-blade service life, the science behind it, and best practices for effective sharpening.

How Dullness Shortens the Service Life of a Double Round-Blade

To understand why sharpening extends a double round-blade’s life, it’s first important to see how dullness harms the blade. A dull double round-blade no longer cuts cleanly; instead, it tears, crushes, or pushes through materials. This inefficiency creates a chain reaction that shortens the blade’s service life:

- Increased Friction: A dull blade’s edge is rounded or jagged, requiring more force to cut through materials. This extra friction generates heat, which can warp the blade or weaken its metal over time. For example, in food processing, a dull double round-blade cutting through tough meats or vegetables will rub against the material, creating heat that damages the blade’s structure.

- Uneven Wear: Dull blades don’t distribute pressure evenly across their edges. This causes certain areas of the blade to wear faster than others, leading to uneven thinning or nicks. Once these weak spots form, the blade is more likely to chip or break during use.

- Excessive Force Damage: Users often apply more pressure to a dull double round-blade to make it cut, increasing stress on the blade’s core and mounting hardware. Over time, this stress can bend the blade, loosen its attachment, or even crack the blade’s center hole, rendering it unusable.

- Material Buildup: Dull blades leave more material residue stuck to their surfaces. This buildup (like food particles, wood fibers, or plastic bits) can corrode the blade or act as an abrasive, further dulling the edge with each use.

In short, a dull double round-blade works harder, wears faster, and is more prone to damage. Without sharpening, these issues compound, leading to premature replacement.

How Sharpening Extends the Service Life of a Double Round-Blade

Sharpening addresses the problems caused by dullness, restoring the double round-blade’s edge and reducing stress on the blade. Here’s how it extends service life:

- Restores Efficient Cutting: Sharpening grinds away the dull, damaged part of the blade’s edge, creating a new, sharp edge. A sharp double round-blade cuts cleanly with less force, reducing friction and heat. This efficient cutting means the blade experiences less wear during each use, slowing down the rate of deterioration.

- Reduces Uneven Wear: By creating a uniform edge, sharpening ensures pressure is distributed evenly across the blade during cutting. This prevents hotspots of wear, keeping the blade’s thickness consistent and reducing the risk of weak spots or cracks.

- Minimizes Stress and Damage: With a sharp edge, less force is needed to cut, lowering stress on the blade’s core and mounting parts. This reduces the chance of bending, warping, or breaking, which are common causes of early blade failure.

- Removes Corrosive Buildup: Sharpening often includes cleaning the blade, removing stuck material or rust that could corrode the metal. This cleaning step protects the blade from chemical damage, preserving its integrity longer.

For example, in packaging industries, a sharp double round-blade cutting through cardboard or plastic films will make clean, quick cuts without dragging. This reduces wear compared to a dull blade that struggles and rubs, extending the blade’s usable life by months or even years.

The Science of Sharpening a Double Round-Blade

Sharpening isn’t just about making a blade “sharp”—it’s a precise process that shapes the blade’s edge to optimize cutting performance and durability. The edge of a double round-blade is a thin, angled surface where the two sides of the blade meet. When sharpened correctly, this edge is straight, smooth, and has the ideal angle for the material it cuts.

- Edge Geometry: Different materials require different edge angles. For example, a double round-blade cutting soft materials like bread or fabric needs a narrower angle (around 20 degrees) for a sharp, delicate edge. A blade cutting hard materials like metal or hardwood needs a wider angle (30 degrees or more) for strength. Sharpening to the right angle ensures the edge stays sharp longer and resists chipping.

- Metal Removal: Sharpening removes a small amount of metal from the blade’s edge. This is necessary to eliminate nicks, burrs, and rounded areas. However, good sharpening removes only enough metal to restore the edge, preserving as much of the blade’s thickness as possible. Removing too much metal during sharpening can thin the blade prematurely, reducing its overall service life.

- Honing vs. Sharpening: Honing (using a steel rod or stone) straightens a slightly dull edge without removing much metal, while sharpening (using grinders or sharpening stones) removes more metal to create a new edge. Regular honing between sharpening sessions can extend the time between full sharpenings, further preserving the blade’s metal.

By maintaining the correct edge geometry and removing only necessary metal, sharpening ensures the double round-blade remains effective for more uses before needing replacement.

Best Practices for Sharpening a Double Round-Blade

To maximize the service life extension from sharpening, it’s important to sharpen a double round-blade correctly. Poor sharpening can damage the blade, reducing its life instead of extending it. Follow these best practices:

- Use the Right Tools: Double round-blades require tools designed for their circular shape. Bench grinders with adjustable rests, specialized round-blade sharpeners, or sharpening stones with guides work best. Avoid using improper tools like file sets, which can create uneven edges.

- Match the Sharpening Method to the Blade Material: Blades made of high-carbon steel, stainless steel, or carbide-tipped require different sharpening techniques. For example, carbide-tipped double round-blades need diamond sharpening tools, as carbide is harder than traditional steel. Using the wrong method can scratch or overheat the blade.

- Maintain Consistent Angle: Keep the sharpening tool at a steady angle relative to the blade’s edge. Most double round-blades have a factory-specified angle (often marked in the blade’s documentation), and deviating from this angle can create a weak edge that dulls quickly.

- Avoid Over-Sharpening: Sharpen only when the blade is noticeably dull. Over-sharpening removes excess metal, thinning the blade and reducing its strength. A good rule is to sharpen when cutting requires more force than usual or when the blade leaves ragged edges.

- Clean and Inspect After Sharpening: After sharpening, clean the blade to remove metal shavings, which can act as abrasives. Inspect the edge for nicks or uneven spots—if present, re-sharpen those areas gently to avoid weakening the blade.

- Hone Regularly: Between sharpenings, use a honing stone or steel to keep the edge straight. Honing takes just a few seconds and can double the time between full sharpening sessions, preserving the blade’s metal.

How Often Should You Sharpen a Double Round-Blade?

The frequency of sharpening depends on how the double round-blade is used, but a general guideline is to sharpen when performance declines. Here are some indicators it’s time to sharpen:

- The blade no longer cuts cleanly, leaving ragged edges or tearing materials.

- More force is needed to make the blade cut through materials.

- Material residue builds up on the blade’s surface more quickly than usual.

- The blade makes unusual noises (like squeaking or grinding) during use, a sign of friction from dullness.

For heavy-use applications (like industrial food processing), a double round-blade may need sharpening weekly. For lighter use (like home woodworking tools), sharpening every few months may suffice. Keeping a log of sharpening dates and blade performance can help identify the ideal schedule for your needs.

FAQ

Can sharpening a double round-blade too much shorten its life?

Yes. Over-sharpening removes excess metal, thinning the blade and making it prone to bending or breaking. Sharpen only when the blade is dull, and avoid removing more metal than necessary.

Does the type of material being cut affect how often a double round-blade needs sharpening?

Absolutely. Cutting abrasive materials (like fiberglass, concrete, or rough wood) dulls the blade faster, requiring more frequent sharpening. Soft materials (like fabric or bread) cause less wear, so sharpening is needed less often.

Can a damaged double round-blade (with chips or cracks) be saved by sharpening?

Minor chips can sometimes be ground away with sharpening, but large cracks or deep nicks often mean the blade is too damaged to repair. Sharpening won’t fix structural issues, and a cracked blade may break during use.

Is it better to sharpen a double round-blade by hand or with a machine?

Machine sharpening (with a proper round-blade sharpener) is more consistent, ensuring even edge geometry. Hand sharpening is possible but requires skill to avoid uneven edges, which can shorten the blade’s life.

How much longer can sharpening extend a double round-blade’s service life?

With proper sharpening, a double round-blade’s service life can be extended by 50% to 100% or more. For example, a blade that would normally last 6 months without sharpening may last 9–12 months with regular sharpening.

Table of Contents

- Can Sharpening Extend the Service Life of a Double Round-Blade?

- How Dullness Shortens the Service Life of a Double Round-Blade

- How Sharpening Extends the Service Life of a Double Round-Blade

- The Science of Sharpening a Double Round-Blade

- Best Practices for Sharpening a Double Round-Blade

- How Often Should You Sharpen a Double Round-Blade?

-

FAQ

- Can sharpening a double round-blade too much shorten its life?

- Does the type of material being cut affect how often a double round-blade needs sharpening?

- Can a damaged double round-blade (with chips or cracks) be saved by sharpening?

- Is it better to sharpen a double round-blade by hand or with a machine?

- How much longer can sharpening extend a double round-blade’s service life?