Does Scheduled Upkeep Stop Round-Blade Failures?

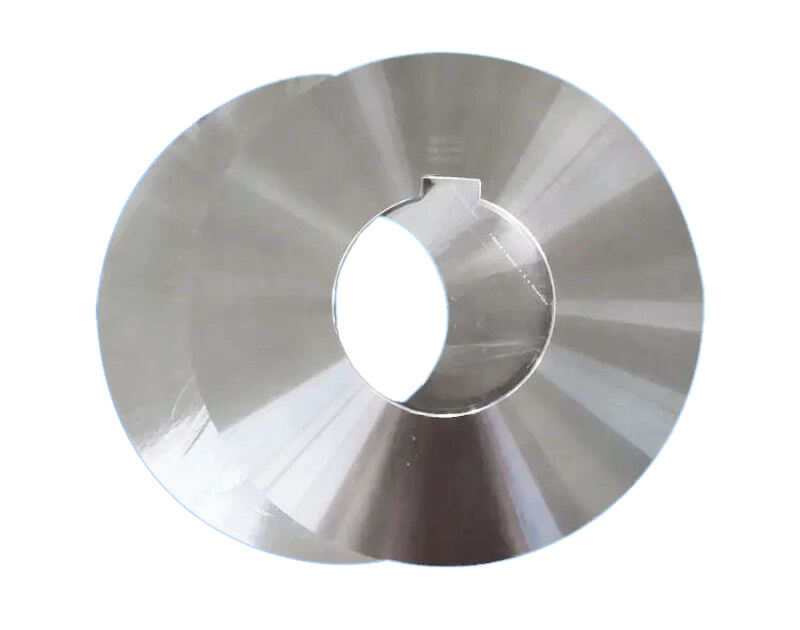

Round-blades are critical tools in industries ranging from food packaging and woodworking to metal fabrication and film slitting. A sudden round-blade failure—whether it’s a broken edge, excessive dullness, or misalignment—can halt production, damage machinery, and even cause safety risks. Many operators wonder if scheduled upkeep (regular maintenance and inspections) can prevent these failures. The answer is clear: while no maintenance plan can eliminate failures entirely, scheduled upkeep significantly reduces the risk of round-blade failures by catching issues early, maintaining performance, and extending blade life. This guide explains how scheduled upkeep prevents round-blade failures, key maintenance tasks, and the benefits for operations that prioritize regular care.

What Causes Round-Blade Failures?

To understand how scheduled upkeep works, it’s first important to identify the common causes of round-blade failures. These failures often stem from preventable issues that worsen over time without maintenance:

- Dullness and Wear: Over time, friction from cutting materials wears down the blade’s edge, making it dull. A dull blade requires more force to cut, increasing stress on the blade and machinery. If left unaddressed, dullness can lead to overheating, warping, or even edge chipping.

- Misalignment: Blades that are not properly aligned with the machine or anvil create uneven pressure during cutting. This uneven pressure causes the blade to wear unevenly, leading to cracks, chips, or breakage.

- Contamination and Corrosion: Debris (like wood chips, plastic fragments, or food particles) can build up on the blade, acting as abrasives that accelerate wear. Moisture or chemicals can cause rust or corrosion, weakening the blade’s material.

- Fatigue and Stress: High-speed rotation or repeated use can create stress on the blade, especially if it’s unbalanced. Over time, this stress leads to micro-cracks, which grow into larger fractures and eventual failure.

- Improper Storage: Blades stored in dirty, damp environments or without protection are prone to damage from rust, dents, or accidental impacts.

Most of these causes develop gradually, making them detectable and fixable with scheduled upkeep before they result in failure.

How Scheduled Upkeep Prevents Round-Blade Failures

Scheduled upkeep involves regular inspections, cleaning, sharpening, and adjustments designed to address the root causes of failure. By incorporating these tasks into a routine, operators can stop failures before they occur.

Regular Inspections Catch Early Warning Signs

Scheduled inspections allow operators to spot small issues before they become major problems. During inspections, operators check for:

- Edge Condition: Signs of dullness (like ragged cuts or increased cutting force), nicks, or chips in the blade’s edge. Even small chips can grow into cracks during use.

- Alignment: Whether the blade sits straight in the machine, with no wobbling or misalignment that could cause uneven wear.

- Balance: Signs of vibration during rotation, which indicates the blade is unbalanced and at risk of stress fractures.

- Contamination: Debris buildup, rust, or corrosion that could weaken the blade or damage the machine.

For example, a weekly inspection might reveal a tiny nick in the blade’s edge. Sharpening the blade immediately removes the nick, preventing it from expanding into a crack during high-speed cutting. Without inspection, that nick could lead to a blade breakage mid-production, causing hours of downtime.

Cleaning Reduces Wear and Corrosion

Debris and residue from cutting materials (like glue, wood sap, or metal shavings) stick to the blade during use. Over time, this buildup acts as an abrasive, wearing down the edge and increasing friction. Moisture in debris can also cause rust, weakening the blade’s material.

Scheduled cleaning removes this buildup:

- After Each Use: Wiping the blade with a clean cloth removes loose debris, preventing it from hardening.

- Weekly Deep Cleaning: Using mild detergents (or specialized cleaners for food-grade blades) removes stubborn residue. For metal blades, drying thoroughly after cleaning prevents rust.

- Decontamination for Food-Grade Blades: Sanitizing blades used in food packaging with food-safe cleaners prevents bacterial growth and corrosion, ensuring compliance with safety standards.

Clean blades cut more efficiently, run cooler, and experience less wear—all of which reduce the risk of failure.

Sharpening Maintains Performance and Reduces Stress

A dull blade is one of the biggest causes of round-blade failures. Dull blades require more force to cut, increasing stress on the blade and machine components. They also generate more heat, which can warp the blade or damage the material being cut.

Scheduled sharpening ensures the blade remains sharp, reducing these risks:

- Timely Sharpening: Following a schedule (e.g., after 8–10 hours of use for woodworking blades, or weekly for food packaging blades) prevents excessive dullness. Sharpening removes worn material, restoring the blade’s edge and reducing cutting force.

- Proper Sharpening Techniques: Using professional sharpening tools ensures the blade’s edge angle and geometry are maintained. Improper sharpening (like uneven grinding) can create weak spots that lead to failure.

- Balancing After Sharpening: Sharpening can sometimes unbalance the blade, so rebalancing during scheduled upkeep ensures smooth rotation and reduces stress.

Sharp blades cut cleanly with less force, minimizing stress and extending the blade’s life.

Alignment and Adjustments Prevent Uneven Wear

Even a slightly misaligned blade creates uneven pressure during cutting, causing one side to wear faster than the other. Over time, this uneven wear leads to cracks, chips, or breakage. Scheduled adjustments ensure the blade remains properly aligned:

- Checking Machine Alignment: Regularly verifying that the blade is correctly positioned in the machine, with proper tension and clearance from the anvil or other components.

- Adjusting for Wear: As blades wear, their dimensions change slightly. Scheduled adjustments to machine settings (like pressure or speed) compensate for this wear, maintaining proper cutting conditions.

- Replacing Wear Parts: Components like blade holders or bearings that support the blade can wear down, causing misalignment. Scheduled upkeep includes replacing these parts before they affect the blade.

Proper alignment ensures even wear, reducing the risk of premature failure.

Proper Storage Protects Blades Between Use

Blades not in use are still at risk of damage from environmental factors or mishandling. Scheduled upkeep includes guidelines for safe storage:

- Clean and Dry Storage: Storing blades in dry, clean cases prevents rust and contamination.

- Protective Covers: Using blade guards or sleeves prevents accidental dents or nicks from other tools.

- Organized Storage: Keeping blades labeled and sorted by type prevents damage from stacking or improper handling.

Protecting blades during storage ensures they remain in good condition, ready for use without hidden damage.

Real-World Impact: How Scheduled Upkeep Reduces Failures

A study of a food packaging plant illustrates the impact of scheduled upkeep. Before implementing a maintenance routine, the plant experienced an average of 3–4 round-blade failures per month, each causing 2–4 hours of downtime. After adopting weekly inspections, biweekly sharpening, and daily cleaning:

- Blade failures dropped to 0–1 per month.

- Downtime from failures decreased by over 80%.

- Blade lifespan increased by 50%, reducing replacement costs.

Similar results are seen in woodworking and metal fabrication, where scheduled upkeep cuts failure rates and extends blade life.

Key Scheduled Upkeep Tasks for Round-Blades

A effective upkeep plan includes these tasks, adjusted based on blade type, material, and usage frequency:

- Daily: Clean the blade after use; check for visible debris or damage.

- Weekly: Inspect edge condition, alignment, and balance; deep clean if needed.

- Monthly: Sharpen the blade (or as needed based on use); adjust machine settings.

- Quarterly: Replace worn machine components; inspect storage conditions.

FAQ

How often should round-blades be sharpened as part of scheduled upkeep?

Sharpening frequency depends on usage and material. For high-volume cutting of abrasive materials (like particleboard), sharpen every 5–10 hours. For light use with soft materials (like paper), sharpen every 20–30 hours.

Can scheduled upkeep prevent all round-blade failures?

No, but it significantly reduces the risk. Unexpected issues (like hitting a foreign object in the material) can still cause failures, but upkeep catches 80–90% of preventable issues.

Is scheduled upkeep more expensive than replacing blades?

No. The cost of maintenance (labor, tools, sharpening) is far lower than the cost of downtime, machine repairs, and frequent blade replacements caused by failures.

What tools are needed for scheduled upkeep of round-blades?

Basic tools include cleaning cloths, mild cleaners, a blade inspection light, sharpening stones or machines, and alignment gauges. Specialized blades may require manufacturer-recommended tools.

How do I create a scheduled upkeep plan for my round-blades?

Start by tracking blade usage and failure causes to identify patterns. Set inspection and maintenance intervals based on these patterns, and adjust as needed. Consult the blade manufacturer for recommendations.

Table of Contents

- Does Scheduled Upkeep Stop Round-Blade Failures?

- What Causes Round-Blade Failures?

- How Scheduled Upkeep Prevents Round-Blade Failures

- Real-World Impact: How Scheduled Upkeep Reduces Failures

- Key Scheduled Upkeep Tasks for Round-Blades

-

FAQ

- How often should round-blades be sharpened as part of scheduled upkeep?

- Can scheduled upkeep prevent all round-blade failures?

- Is scheduled upkeep more expensive than replacing blades?

- What tools are needed for scheduled upkeep of round-blades?

- How do I create a scheduled upkeep plan for my round-blades?