How Can I Tell if My Circular Blade Is Dull or Damaged?

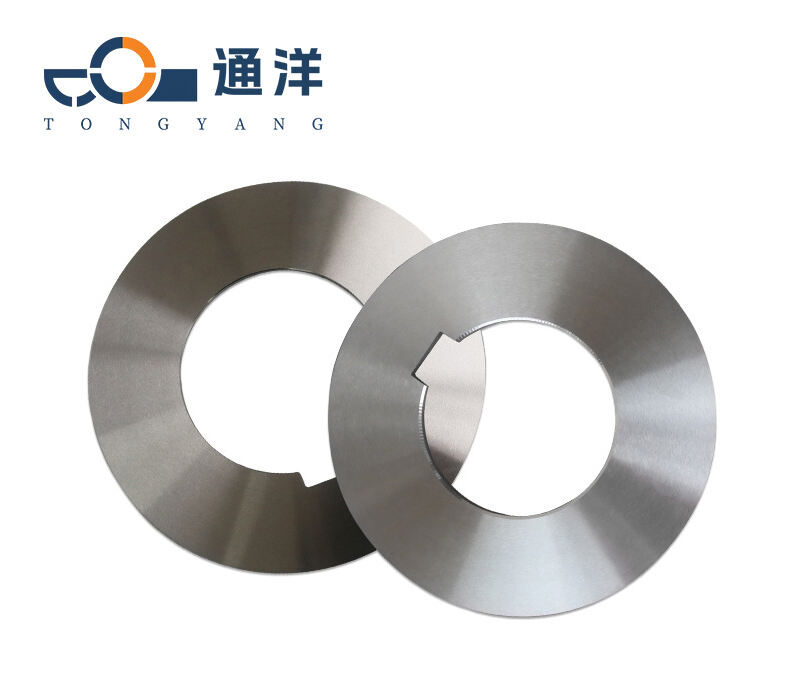

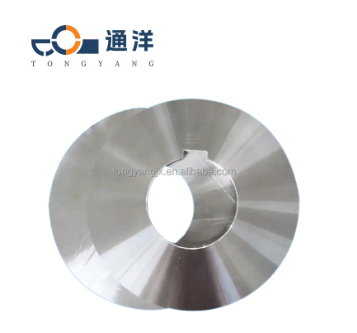

A circular blade is a key tool in many projects, from woodworking and metal fabrication to packaging and DIY home repairs. A sharp, undamaged circular blade makes clean cuts efficiently, while a dull or damaged one can ruin work, slow progress, and even cause accidents. Knowing how to spot signs of dullness or damage helps you maintain performance, avoid waste, and keep your tools safe. This guide explains the clear signs that your circular blade is dull or damaged, how to check for them, and why addressing these issues quickly matters.

Signs Your Circular Blade Is Dull

Dullness happens over time as the blade’s edge wears down from friction and use. It’s the most common issue with circular blades, but it’s easy to miss if you don’t know what to look for. Here are the main signs:

1. Ragged or Uneven Cuts

A sharp circular blade cuts through material in a smooth, straight line, leaving clean edges. A dull blade, however, tears or crushes material instead of slicing it. For example:

- In wood, a dull blade leaves splintered edges, especially on the bottom or back of the cut.

- In metal, it creates burrs (rough, raised edges) or jagged lines instead of smooth finishes.

- In plastic or fabric, it may stretch the material before cutting, leading to uneven or frayed edges.

If your cuts look messy no matter how careful you are, the blade is likely dull.

2. Increased Effort or Machine Strain

A sharp circular blade cuts with minimal force, gliding through material easily. A dull blade requires more pressure to make progress, which you’ll notice in two ways:

- Manual Effort: If you’re using a hand-held saw, you’ll have to push harder or apply more pressure to keep the blade moving.

- Machine Strain: Power saws with dull blades may slow down, make straining noises, or even bog down completely. The motor might overheat, indicated by a burning smell or reduced speed.

This extra effort not only makes work harder but also puts stress on the machine, increasing the risk of damage.

3. Burning or Discoloration on Material

Friction from a dull circular blade generates excess heat as it struggles to cut. This heat can leave visible marks on the material:

- Wood may have dark burn lines along the cut edge.

- Plastic or vinyl may melt slightly, leaving a sticky residue or warped edges.

- Metal might discolor, turning blue or black in spots where the blade overheated.

Burning is a clear sign the blade is dull and working too hard—continuing to use it can ruin your material and damage the blade further.

4. Vibrations or Unusual Noises

A sharp circular blade spins smoothly, making a steady, low noise. A dull blade, however, vibrates more because it doesn’t cut cleanly. You’ll notice:

- Shaking: The saw or machine may vibrate in your hands or on the workbench.

- High-Pitched Sounds: A “chattering” or squealing noise as the blade catches and releases the material.

- Uneven Rhythm: The blade may skip or jerk instead of moving steadily through the material.

Vibrations not only make cutting harder but also accelerate wear on both the blade and the machine.

5. Material Pinching or Jamming

A dull circular blade doesn’t cut through material quickly, so the material can close in on the blade, causing it to get stuck. This is common in woodworking, where a dull blade may pinch in the cut, requiring you to force it free. Jamming increases the risk of kickback (the saw jerking backward), which is dangerous. If your blade frequently gets stuck, it’s almost certainly dull.

Signs Your Circular Blade Is Damaged

Damage is different from dullness—it involves physical flaws in the blade that can’t be fixed by sharpening. Damaged blades are unsafe to use and can cause serious accidents if ignored. Here are the key signs of damage:

1. Nicks or Chips in the Blade Edge

Nicks are small, shallow indentations in the blade’s edge, while chips are larger pieces missing from the teeth. They’re often caused by hitting hard objects like nails, staples, or rocks hidden in the material. You can spot them by:

- Visual Inspection: Holding the blade up to light and looking for gaps or uneven spots along the edge.

- Tactile Check: Running a finger gently along the edge (when the blade is cool and not spinning) to feel for rough, jagged spots.

Nicks and chips make cuts uneven and can cause the blade to catch on material, leading to kickback or further damage.

2. Cracks in the Blade Body

Cracks are serious damage that can cause the blade to break during use. They may appear:

- Near the arbor hole (the center hole that attaches to the machine).

- Along the blade’s body, especially between the teeth.

- At the edge, spreading from a nick or chip.

Cracks often form due to excessive stress, like using a blade that’s too small for the material, or from dropping the blade. Even small cracks can grow quickly when the blade spins at high speeds, making the blade dangerous to use.

3. Warping or Bent Blade

A circular blade must be perfectly flat to cut evenly. Warping (a slight curve or twist in the blade) or bending (a more obvious deformation) can happen if the blade overheats, is dropped, or is tightened too much on the machine. Signs include:

- Uneven Cuts: The blade cuts deeper on one side than the other.

- Rubbing Sounds: The blade scrapes against the machine’s guard or throat plate as it spins.

- Visual Distortion: Holding the blade up to a straight edge (like a ruler) shows gaps between the blade and the straight edge.

Warped blades create uneven pressure, leading to poor cuts and increased machine wear.

4. Rust or Corrosion

Rust forms when moisture reacts with the blade’s metal, creating reddish-brown spots. Corrosion is more severe, eating away at the metal and weakening the blade. Signs include:

- Flaky, discolored areas on the blade’s surface.

- Pitting (small holes) in the metal, especially near the edge.

- Stiff movement if rust builds up around the arbor hole.

Rust and corrosion weaken the blade, making it more prone to cracking or breaking. They also make cuts rougher by damaging the blade’s edge.

5. Loose or Missing Teeth

On blades with individual teeth (like saw blades for wood or metal), teeth can become loose or fall off entirely. This is usually caused by severe impact (like hitting a hard object) or wear from using a blade beyond its lifespan. Missing teeth create large gaps in the blade’s edge, leading to uneven cuts and increased vibration.

How to Check Your Circular Blade for Dullness or Damage

Regular checks help catch issues early. Follow these steps to inspect your circular blade:

1. Safety First

- Ensure the machine is unplugged or turned off, and the blade has stopped spinning completely.

- Wear gloves to protect your hands from sharp edges or rust.

2. Visual Inspection

- Hold the blade up to a bright light and examine the entire edge for nicks, chips, or unevenness.

- Check the blade’s body for cracks, rust, or warping.

- Look at the arbor hole for signs of wear or damage, like uneven edges or rust.

3. Test Cuts

Use a scrap piece of material to make a test cut:

- A dull blade will produce ragged edges, require extra force, or cause burning.

- A damaged blade may vibrate, make unusual noises, or cut unevenly.

4. Clean Before Inspecting

Debris like wood chips, plastic, or metal shavings can hide damage. Clean the blade with a brush and mild detergent first, then dry it thoroughly before inspecting.

What to Do If Your Circular Blade Is Dull or Damaged

- If Dull: Sharpen the blade using a sharpening stone, machine, or professional service. Sharpening restores the edge and extends the blade’s life.

- If Damaged (Nicks/Chips): Small nicks can sometimes be fixed by sharpening, which grinds away the damaged area. Large chips or multiple nicks mean the blade needs replacement.

- If Cracked, Warped, or Rust-Corroded: Replace the blade immediately. These issues can’t be repaired, and using the blade is unsafe.

FAQ

Can a dull circular blade be sharpened, or does it need replacement?

Most dull blades can be sharpened 3–5 times before they become too thin. If sharpening doesn’t improve performance, it’s time to replace the blade.

How often should I check my circular blade for damage?

Inspect the blade before each use, especially if you’re cutting material that might contain hidden debris (like reclaimed wood). Do a deeper check weekly for heavy-use blades.

Is it safe to use a blade with small nicks?

Small nicks can be sharpened out, but using a nicked blade before sharpening increases the risk of uneven cuts or kickback. It’s better to sharpen or replace it first.

What causes a circular blade to crack?

Cracks are often caused by hitting hard objects, overheating, using the wrong blade for the material, or dropping the blade.

How can I prevent my circular blade from getting dull or damaged?

Clean the blade after use, store it in a dry case, avoid cutting material with hidden debris, and sharpen regularly. Use the right blade for your material and machine.