Introduction

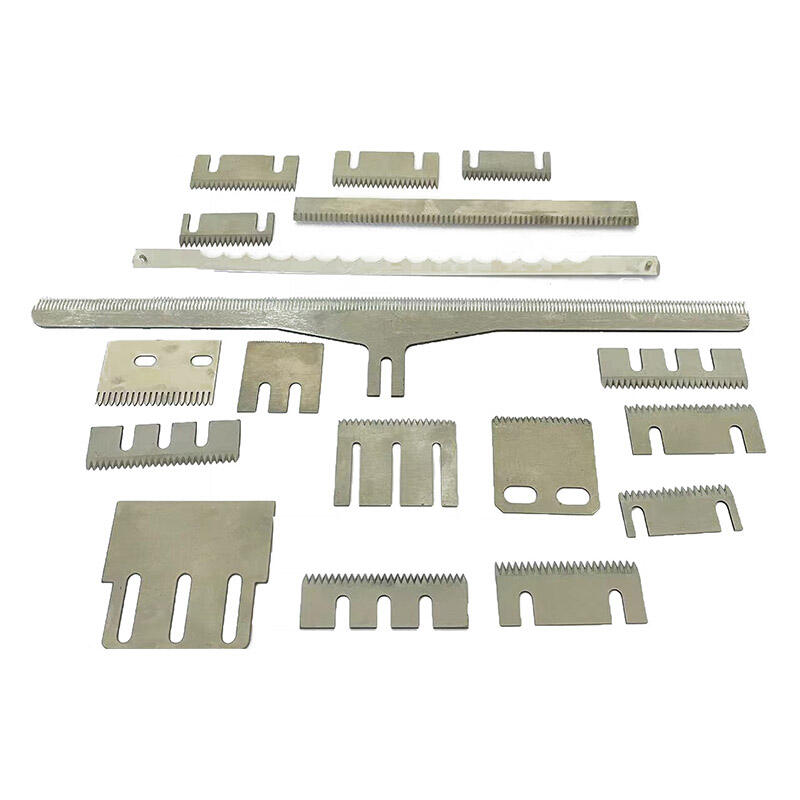

Precision cutting tools are essential for smooth, efficient work. The choice between carbide-tipped circular saw blades and high-speed steel blades impacts workflow. Each has merits for specific uses. This exploration delves into their compositions, performances, and applications to inform critical decisions.

Carbide Circular Saws

Renowned for resilience, carbide saws last through extended exertions. Constructed from the diamond-hard tungsten carbide bonded to steel cores, they withstand wear admirably.

Carbide's Advantages

Stamina and Longevity: Carbide saws outperform steel saws significantly, proving economical ultimately.

Resilience to Attrition: Harder than steel, carbide resists wear from abrasives better.

Keenness Keeps: Retaining sharpness longer, they need sharpening less often, streamlining processes.

Multi-Material Mastery: Versatile across woods, metals, and composites, carbide copes commendably.

High-Speed Steel Saws

Steel saws suit speedy, intermittent cutting. Affordable initially, they demand frequent resharpening as edges erode quickly. For light-duty tasks not requiring longevity, steel satisfies.

Carbide Cutters are Delicate but Sharp

Carbide saw tips lose their hardness at elevated heat levels, an issue when sawing some materials. While very keen, carbide is brittle and may chip with undue force or striking. Carbide-tipped saws also have a higher initial cost than high-speed steel options.

High-Speed Metal is Durable and Enduring

High-speed steel saw blades comprise steel alloys that preserve sharpness at high slicing velocities. Known for withstanding blows without fracturing, HSS saws generate less heat when cutting swiftly.

High-Speed Steel Saws have Certain Benefits

HSS saw blades retain their edge as temperatures rise from quick slicing. The flex in HSS causes it to crack or chip less under pressure. As HSS saws are generally less expensive than carbide varieties, they appeal to budgets that are tighter. HSS saws can also be resharpened more effortlessly, expanding their usable lifetime.

Disadvantages of HSS Blades

Compared to carbide blades, HSS saw blades are less durable and require more frequent sharpening. While HSS blades can cut various materials, they may struggle with harder substances like dense wood or certain metals that carbide performs better on. Additionally, the cutting edges of HSS dull quicker, necessitating regular maintenance to restore their sharpness.

Material Compatibility and Applications

Carbide saw blades tend to be the preferred choice for cutting harder materials like metal composites and wood due to their resilience and long-lasting sharpness. On the contrary, softer substances, plastics, and some metals are where HSS blades have an advantage thanks to their shock resistance and cost-effectiveness, especially when constant sharpening is not critical.

Performance Assessment

Generally speaking, carbide saw blades cut faster and more efficiently because of their hardness and sharpness retention over time. However, HSS blades can be the more budget-friendly selection for less demanding jobs or situations where frequent sharpening is not a concern.

Safety Considerations

Regardless of the blade type, safety should remain the utmost priority. Appropriate safety gear such as protective eyewear and earplugs are mandatory for both carbide-tipped and HSS saw blades. Additionally, adhering to best practices regarding blade installation, operation and maintenance is imperative to prevent harm.

Consider Your Needs

The decision between a carbide-tipped circular blade and a high-speed steel alternative hinges on the demands of the job, the material being cut and the budget. Carbide-tipped saw blades offer long-lasting durability and versatility but require a steeper investment, while HSS blades provide a more cost-effective choice for less rigorous tasks with satisfactory performance. Weighing these differences carefully aids in making an informed choice leading to optimal cutting outcomes and longevity of use over projects.

Table of Contents

- Introduction

- Carbide Circular Saws

- Carbide's Advantages

- Carbide Cutters are Delicate but Sharp

- High-Speed Metal is Durable and Enduring

- High-Speed Steel Saws have Certain Benefits

- Disadvantages of HSS Blades

- Material Compatibility and Applications

- Performance Assessment

- Safety Considerations

- Consider Your Needs