Introduction

Be it woodworking or metal fabrication, all industries just cannot do away with ′round blades. Blade longevity is a huge driver of productivity and expenses in the business. Keeping a round blade flying economically makes sense, as does netting performance spares post fact on homogenous designs. A definitive reference guide the round blades life span.

Round Blade: The Material and Coatings

First, you must understand the type of coating and coatings that are used when attempting to extend the life of a round blade. Normal tools materials which are used are check out high speed steel (hss), carbide and natural diamond cut outs. Each material has its own performance features, which ultimately impact durability. Another example, HSS blades have an extended range of materials they can cut through; diamond-coated types allow you to use your blade on harder materials like stone or concrete. Also for maintenance practices correct there sense of the material itself is required.

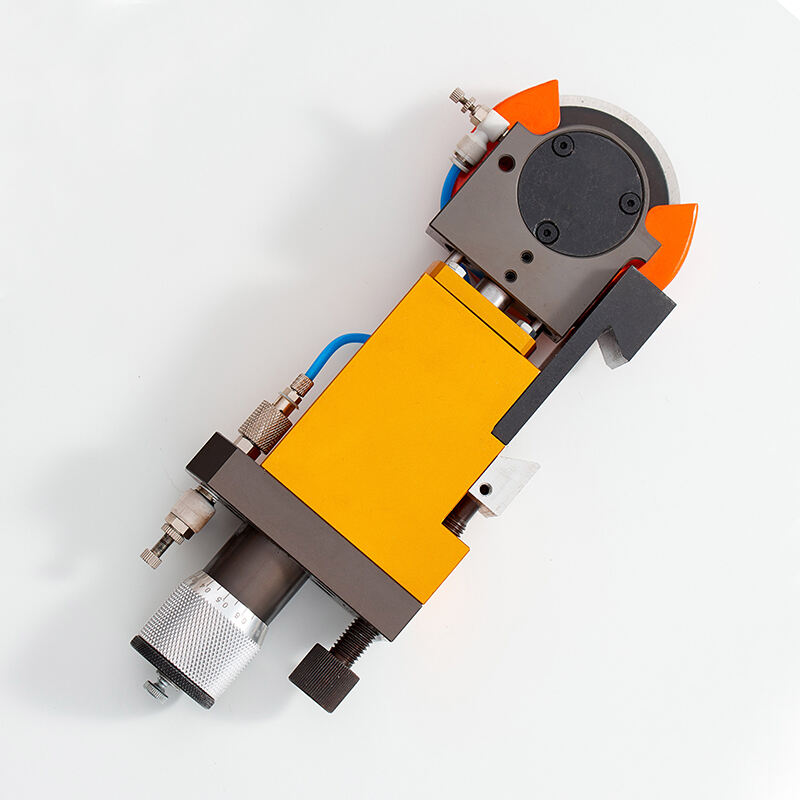

Installation and Working with Proper blade

There are two critical points to avoid harming the blade: one is careful installation, and the other is proper use. 0.001mm Run out The blade should be aligned with axis of machine and do not stammer as that will make surface wear of the surfaces which may ruin them. Never touch blades without gloves — oil from your skin will transfer to metal and cause rust! Hell, don't even drop them and as the most stable blade will eventually have a crack or chip run along its integrity!

Frequent Cleaning and Upkeep

How much does cleaning your blades matter when it comes to performance and durability? Blades should be swept clear of pitch, sap or other debris that can contribute to rusting and clog cutting after use. Using a soft brush, and the cleaning solutions that would be not harmful to the blade structure. A pitch remover helps in case of blades when it comes to cutting wood. Make sure to dry the blade off before putting it away so you do not let any rust form.

A Process of Sharpening and Fine-tuning the Blade

Sharpening — Absolutely the first thing about knife edge. Blades that are not sharp obstruct your goal to maintain; it also increases accidents on the field. Tip: The sharpener should be determined by the material of the blade and brought back to its proper sharpening angles as specified in the manufacturers guidelines. And then, sharpening, and balancing the blade so that it actually ran without chewing up belts or pulleys. Otherwise, the vibrating blade will burn out prematurely.

Low-cost LPT RUST Preventative & Lubricant

A nonmetallic workhorse for the cutting edge that constitutes half of the blades. Then it is cut for use (thereby minimizing abrasion & wear with proper lubrication handling). Then lubricate to minimize some of that heat and friction, and cut. As simple anti–rust solution available online that minimizes rust but especially work in case of humid environment exists, apply light spray of rust protector or oil blade when you not use it.

Look for any damage and wear

So, it requires regular inspection for damage or wear of the blanket. Inspect for any cracks or chips, even warping — which limits the ability of the blade to perform its purpose. Inspect the edge, whether it needs sharpening or a new blade. This will help identify the problems ahead of time, and will thus reduce premature wear and tear on blades.

Round Blade Storage Solutions

Perhaps none greater when it pertains to correct storage, as this will keep blades from being ruined or dulled while not in use. Keeping the blades away in a clean, dry place minimizes rust build-up. Use blade cases, sheaths or magnetic strips to keep blades organized and protected. Not only will this means your blades are stored away safely, but keeping the drawer or surface free from clutter will prevent any accidents developing.

Giving What Material Maintenance Deems Necessary

Not every type of blade is made from the same material so they may require different maintenance styles. Some coatings, like diamond-coated blades may require specific cleaning solutions to safeguard the coating itself. Always refer to the manufacturer for specific care instructions for that type of material. Additionally, coated or composite blades may have some specific maintenance sawing needs.

Training and Safety

Make sure that all operators are trained in how to use and maintain the blade properly, including ensuring safety. If not in use, the rib of a blade will corrode but if practiced well can prolong the service life of this long piece and keep people who operate it safe. Safety precautions including personal protection equipment and blade safety devices should be employed during the operation and use of each unit.

Cost vs Benefit of Keeping Blades in Sharper conditions

This is why blade maintenance is worth investing time and resources. Investing in initial maintenance is however a much smaller cost than repeatedly replacing blades and losing productivity using a well maintained blade. That decreases the frequency that changing blades need to happen, which saves residents time and pushes the purpose of blades as far as it can go.

Conclusion

To sum it up, improving the round blades life cycle is necessary to ensure high-level productivity and keeping costs constant. Being aware of the material which the blades used, proper installation and handling practices together with an appropriate maintenance routine will help in maximizing your round blades performance and service life. The trick to successful blade care is remembering your habits with the blade and adapting to what kind of material it will be used on. When done correctly that means your rounded blade will keep working nicely for each of the cutting jobs which you need them to.

Table of Contents

- Introduction

- Round Blade: The Material and Coatings

- Installation and Working with Proper blade

- Frequent Cleaning and Upkeep

- A Process of Sharpening and Fine-tuning the Blade

- Low-cost LPT RUST Preventative & Lubricant

- Look for any damage and wear

- Round Blade Storage Solutions

- Giving What Material Maintenance Deems Necessary

- Training and Safety

- Cost vs Benefit of Keeping Blades in Sharper conditions

- Conclusion